Introduction

Conservation Agriculture enables production systems to respond favorably to two perspectives related to climate change, soil degradation and the costs of energy and inputs in the production (Derpsch et al., 2010).

One of the agronomic parameters to assess for determining the efficacy of tillage systems and agrotechnical aspects, is the emergence of plants. Fonseca (1997) and Ribeiro (1998), cited by Alves et al. (2003) showed that crop germination is not influenced by the variation of the speed of movement of the tractor-sowing machine set. On investigations performed by Rodrigues de L. et al. (2010), conventional tillage system provided less suitable conditions for the emergence of bean plants, with respect to minimum tillage.

On the other hand, it is important to know the power demand of agricultural implements, due to its impact on fuel consumption. To do that, it is necessary to identify that there are factors to be considered for a better use of the energy source, such as, the characteristics of the implement, soil type, the content of moisture and clay, the depth and speed of work, whose increase reduces fuel consumption by work area, caused by increasing the work capacity of the whole set of implements. Almeida et al. (2010), showed the relationship between these factors, obtaining an increase in the field capacity together with the increase in working speed.

Salvador et al. (2008), cited by Fernandes et al. (2012) and Milagres et al. (2015), referred that, by increasing the speed of operation, there was an increase in strength and traction power in grain seeders.

Furlani et al. (2008) and Almeida et al. (2010), obtained an increase in hourly fuel consumption, traction and power pull force, while increasing the working speed of the mechanized set, similar to the one obtained by Modernel et al. (2013) and Macedo et al. (2016), who got average values for the power drawbar at speeds of 5.5 and 7.0 km·h-1, 22.17 and 28.33 kW, respectively.

The above mentioned parameters are also influenced by the soil management. According to that, Menezes (2013) verified a minimum increase traction power and energy consumption (MJ·ha-1) in soybean planting of the tillage system reduced with scarification, compared to conventional tillage. However, Kianil and Houshyar (2012) showed an increase in the energy consumed in bean planting using conventional tillage system compared to chisel tillage.

Tillage is a main operation in a crop production system that affects or favors the development of the crop, the quality of the soil and the consumption of energy. Based on that, the objective of this research was to evaluate the operational performance of a tractor bean-seeder set, considering two tillage systems and two speed steps.

Methods

The experiment was carried out in a soil classified as Red-Yellow Dystrophic Clay according to EMBRAPA (1997), belonging to the Faculty of Agronomy in Federal University of Viçosa. The experimental area was approximately 0.25 ha, with 100% of vegetable coverage formed by remains of corn from the previous and weed harvest with predominance of Guinea grass (Panicum maximum) and smooth sow-thistle (Sonchus oleraceus).

Each experimental plot occupied an area of 60 m2, measuring 20 m long and 3 m wide, grouped in blocks separated by strips of 1 m wide.

The experiment was installed in a scheme of subdivided plots, having the gear in the plots and conventional tillage (SLC) and minimum (SLM) systems in the subplots. It had a delineation of random blocks with four repetitions totaling 16 experimental plots. Theoretical working capacity of the units, the traction force, the traction power, the hourly fuel consumption and per area worked and the energy consumption of the operation were evaluated. The results for the parameters evaluated were processed in the SPSS computer statistical package Statistics 21. The study consisted in one analysis of variance to the variable responses for a level of significance of 95% (p <0.05).

Two tire tractors were used. One of them was John Deere brand, model 5705.4x2 TDA traction, with 63 kW (85 HP) of power and to form the convoy and measure the tractive force of the implements suspended to the tractor, the authors worked with a VALTRA Valmet model tractor, E800 model, 4x2 TDA drive, 63 kW (85 HP) and a Seed-Max PC 2125 seed drill-fertilizer machine for direct seeding, with three lines spaced at 0.45 m and 870 kg in weight.

To evaluate the performance of the seeding-tractor assembly, the following gears were used: B1 (position B of the selector lever of groups and position one of the shift lever) and B2 (position B of the selector lever of groups and position two of the lever change), with the engine at 2400 min-1. The displacement speed of the machining set was obtained with the use of a Doppler radar unit installed on the tractor.

To estimate the tensile force required by the implement, the Kratos load cell, with a capacity of 50 kN, was installed between the drawbar of the John Deere tractor and the front hitch of the VALTRA Valmet tractor on a fixed support to keep it in horizontal position and avoid strong impacts. The forces obtained during the path of the plot were added and the result was divided by the number of recorded data. The power in the drawbar was calculated through the product of the traction force by the speed of displacement, according to ASAE S313.2. (1994). The theoretical capacity of work was determined by multiplying the work speed by the work width of the planter. The hourly consumption of fuel was acquired by means of a FLOWMATE M-III flow meter, model LSN40, with impulse-type output signal and precision of 1 mL·impulse-1, installed in the tractor's power system, and dividing this value by theoretical work capacity, fuel consumption per hectare was obtained.

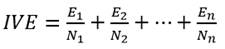

The energy needed to perform the mechanized operation was calculated using the equation utilized by Trujillo et al. (2013).

Where

E |

- Energy required per area sown (MJ·ha-1); |

P |

- Power required by the planter on the drawbar (kW); |

CTt |

- Theoretical work capacity of the set (ha·h-1). |

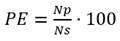

The percentage and index of emergency speed of the plants were evaluated in a length of 10 m in the central line of the plot. The counting of the plants began on the first day of emergency and ended when it stabilized. For the determination of the emergency velocity index (EVI), Equation 2 was used taken from Maguire (1962) and utilized by Zambiazzi et al. (2014) and Kaspary et al. (2017).

Where

E1, E2, En |

- number of plants emerged in the first, second and last count; |

N1, N2, Nn |

- number of days from sowing to the first, second and last count. |

The emergency percentage (PE) was established according to Equation 3.

Results and Discussions

In B1 gear an average speed of 5,06 km·h-1 was reached, while in B2, gear the average speed established was 6,99 km·h-1.

In Table 1, the means of the variables shown are very representative taking into account the low dispersion of the data shown by the variation coefficients. The ANOVA does not report significant influence of the gear on the rate of speed and the percentage of emergency, as well as for the number of plants per m, which coincides with the results obtained by Alves et al. (2003).

The tillage systems did not affect the parameters measured in Chart 1 related to the emergence of the plants, which does not coincide with that obtained by Rodrigues de L. et al. (2010).

Similar to what was achieved by Furlani et al. (2008), Almeida et al. (2010), Modernel da Silveira et al. (2013) and Macedo et al. (2016), the values of force and traction power are shown in Table 2, which express the effect of the increase in the speed of displacement (95% confidence) on these variables. The efficiency of traction in both gears is low, being able to use a lower power tractor.

The tillage systems significantly influenced the FT and PT, with higher SLC values, explained by the greater volume of earth mobilized by the seeder organs of the planter when the ground was more shredded, while in the SLM the furrowing organs of the planter only separated the small soil aggregates that remained in the superficial layer of the soil.

The working capacity of the seeding-tractor assembly and the hourly consumption of fuel, shown in Table 3, increased with the increase of the working speed, agreeing with Almeida et al. (2010), and had a statistical significance for a 95% confidence. The non-influence of the tillage systems on these parameters could be observed, reporting differences that are not statistically significant.

It was demonstrated that the increase of the working speed from 5.06 to 6.99 km·h-1 for planting, had no significant influence on fuel consumption per ha at 95% confidence and there were statistically significant differences were reported in the tillage systems. The SLM consumes less Diesel, which demonstrates the repercussion of the rolling resistance in the SLC, since the soil is looser.

The energy invested in working one hectare of soil, shown in Table 4, expresses its statistically significant variability influenced by the factors taken into account, with a tendency to increase according to the increase in the speed of work.

A higher energy consumption was reported in the sowing for the SLC given by a higher traction power, disagreeing with that obtained by Menezes (2013) and concordant with Kianil y Houshyar (2012).

TABLE 1 Means of indexes of emergency speed (IVE), percentage of emergency (PE) and plants per linear meter (P / m), in relation to the tillage systems and the work gear

| IVE | PE | P/m | ||||

|---|---|---|---|---|---|---|

| Gear | Gear | Gear | ||||

| B1 | B2 | B1 | B2 | B1 | B2 | |

| SLC | 18.77 a* | 19.09 a | 76.47 a | 85.30 a | 11.75 a | 12.50 a |

| SLM | 18.50 a | 19.56 a | 74.47 a | 79.01 a | 11.00 a | 11.50 a |

| CV (%) | 13.9 | 11.5 | 12 | |||

* Means followed by the same letter are not statistically different from each other, with a significance level of 5%.

TABLE 2 Tensile Force Means (FT) and Traction Power (PT), in the sowing of the different tillage systems, in relation to the work gear

| FT (kgf) | PT (kW) | |||

|---|---|---|---|---|

| Gear | Gear | |||

| B1 | B2 | B1 | B2 | |

| SLC | 211.31 a* | 272.6 c | 2.89 a | 4.84 c |

| SLM | 131.92 b | 186.55 d | 1.81 b | 3.56 d |

| CV (%) | 27 | 35 | ||

* Means followed by the same letter are not statistically different from each other, with a significance level of 5%.

TABLE 3 Means of theoretical work capacity (TC), hourly consumption of fuel and fuel consumption by area in the sowing of the different farming systems, in relation to the work gear

| CT (ha·h-1) | L·h-1 | L·ha-1 | ||||

|---|---|---|---|---|---|---|

| Gear | Gear | Gear | ||||

| B1 | B2 | B1 | B2 | B1 | B2 | |

| SLC | 0.452a* | 0.585b | 7.38 a | 9.78 b | 16.35 a | 16.70 a |

| SLM | 0.454a | 0.630b | 7.00 a | 9.43 b | 15.42 b | 14.97 b |

| CV (%) | 15 | 5 | 15 | |||

* Means followed by the same lowercase letter, do not differ statistically from each other, with significance level of 5%.

TABLE 4 Means of Energy Consumption (MJ·ha-1) in the sowing of the different tillage systems, in relation to the work gear

| MJ·ha-1 | ||

|---|---|---|

| Work March | ||

| B1 | B2 | |

| SLC | 23.03 a* | 29.70 c |

| SLM | 14.38 b | 20.33 d |

| CV (%) | 27 | |

* Means followed by the same lowercase letter, do not differ statistically from each other, with significance level of 5%.

Conclusions

The tillage systems did not affect the emergency speed index (IVE).

It is recommended to use B2 gear because it offers less power and energy consumption (MJ·ha-1).

Fuel consumption per hectare and energy consumption (MJ·ha-1) were lower for the minimum tillage system.

The results for bean planting are more advantageous in the minimum tillage system.