Mi SciELO

Servicios Personalizados

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Ingeniería Energética

versión On-line ISSN 1815-5901

Energética vol.37 no.1 La Habana ene.-abr. 2016

APLICACIONES INDUSTRIALES

Feasibility evaluation of two solar cooling systems applied to a cuban hotel. Comparative analysis

Evaluacion de factibilidad del uso dos sistemas climatización solar aplicado a un hotel cubano. Análisis comparativo

Msc. Yamile Díaz Torres, Msc.Yarelis Valdivia Nodal, Dr.José Pedro Monteagudo Yanes, Msc. Yudit Miranda Torres

Centre for Studies of Energy and Environment (CEEMA) of the Cienfuegos University

ABSTRACT

The article presents an analysis of technical and economic feasibility of using two configurations of solar cooling in a Cuban hotel. HVAC hybrid schemes are: a cooler of ice water vapor compression (chiller) interconnected in parallel with a smaller capacity chiller, first with a solar-powered absorption cooling system (SACS), and then with a photovoltaic cooling system(PSC). Both were simulated taking into account the weather conditions in the region, thermodynamic calculation methodologies and principles that govern these technologies. The results show that the use of these alternatives contributes to reducing energy consumption and the environmental impact of heating, ventilation and air conditioning systems (HVAC). Economic analysis highlights that PCS is more favorable than the SACS taking into account the cooling cost generation (CCG) but energy assessment indicates that SACS has higher thermal performance for the case study to which it is applied.

Key words: chiller; feasibility analysis; photovoltaic cooling system; solar-powered absorption cooling system.

RESUMEN

El artículo presenta un análisis de factibilidad técnica y económica de uso de dos configuraciones de climatización solar en un hotel cubano. Los esquemas de climatización híbridas son: una enfriadora de agua helada de compresión de vapor (chiller) interconectada en paralelo con una enfriadora de absorción asistida con energía solar térmica (SACS, siglas en inglés), y posteriormente con un chiller asistido por un sistema solar fotovoltaico (PSC, siglas en ingles). Ambos fueron simulados teniendo en cuenta las condiciones meteorológicas de la región, metodologías de cálculo y principios termodinámicos que gobiernan estos sistemas. Los resultados muestran que el uso de estas alternativas contribuye a la reducción del consumo energético y el impacto ambiental de los sistemas calefacción, ventilación y aire acondicionado (HVAC, siglas en inglés). El análisis económico resalta que PCS es más favorable que el SACS, teniendo en cuenta el costo de generación de frío (CCG, siglas en inglés) pero la evaluación energética indica que este último posee mayores prestaciones térmicas para el caso de estudio al cual se le aplica.

Palabras clave: chiller; análisis de factibilidad; sistema de climatización solar fotovoltaica; sistema de climatización solar por absorción .

INTRODUCCIÓN

Solar energy could supply all the present and the future energy needs of the world on continuing basis. This makes it one of the most promising of the unconventional energy source[1].

The use of solar energy in applications such as refrigeration has become an attractive solution in view of the energetic sustainability. In this scenario where it is evident the increased use of fossil fuels for air conditioning of buildings, solar cooling technology seems to be a promising alternative to conventional electrical driven units. The main advantage of solar cooling systems is the coincidence in time between cooling demand from the building and energy supply in the form of solar irradiance. This implies the reduction of primary energy consumption and the decrease of global warning impact of HVAC systems. Absorption refrigeration systems are not yet competitive to mechanical compression ones. For that reason, research and development activities are necessary in order to reduce the cost of using solar assisted air conditioning in buildings.

Solar cooling literature is rich in papers that assess, develop and optimize a wide variety of solar thermal cooling options, particularly absorption cooling systems. Mokhtar et al. proposed a methodology for assessing solar cooling technologies based on the performance of each solar cooling technology as a system taking into account cost and performance parameters in addition to important boundary conditions of weather and cooling demand.[2] Results showed that large-scale cooling plant options are the most economical. On a smaller scale, Fresnel concentrators and thin film photovoltaic (PV) cells are the most economically viable. In terms of overall efficiency however multicrystalline PV cells with vapor compression chillers were the most efficient option of all. Solar resource availability is a major factor in determining the most suitable solar cooling technology for a certain location.

Otanicar et al.analyzed a variety of solar cooling schemes and revealed some keys details regarding the choice of the system taking into account economically and environmentally aspects: For solar electric cooling system, the cost is highly dependent on the system coefficient of performance (COP) when photovoltaic (PV) prices remain at the current levels but when prices are lowered the impact of COP on cost diminishes.[3] For solar thermal cooling, the cost of solar collection is much lower as a percentage of the overall cost, but the cost of the refrigeration system represents a larger percentage of the total cost. Additionally, the paper reveals that the costs for solar thermal cooling are not projected to decrease as much as PV cooling over the next 20 years due to the relatively stable cost of collection and storage. The tourism sector is one of the main industries in Cuba, also high consumer of electricity, where it is known that 60% of electricity consumption is due to HVAC equipment. In the country using solar cooling technologies discussed above are not recorded. In this scenario the real potential of these systems are not known taking into account the climatic conditions of the region. The objective of this research is to investigate the thermal performance of the operation of the two schemes solar cooling, a SACS and a PSC system using mathematical models to predict the savings in energy and reduction in CO2 emissions. In order to verify the systems’ overall performance, the proposed methodologies is implemented for a hotel facility and the developed model in this study presents a comprehensive analysis that suits Cuba climate and an economic assessment based on the commercialized system components which are commonly existed. The last step was the comparison of both systems in order to find a better solution to apply a hybrid scheme for a cooling production.

GENERAL DESCRIPTION OF THE THERMAL COOLING SYSTEM WITHOUT ANY BACKUP

The SACS consists basically of thermal collectors, a hot water storage tank, lithium bromide solution (LiBr)/water simple effect absorption chiller and a cooling tower which is shown schematically in figure 1. The systems include domestic hot water (DHW) production.

The operation of the system described above generates demand and energy charges which can be assessed using the basic energy balance equations presented by the mathematical models used by Ghait and Abussita , with key assumptions that govern this technology: [5]

- The system is assumed to be under-steady state conditions.

- All phases are in thermal and mechanical equilibrium.

- The water temperature in the tank is uniform.

- Shading of collector absorber plate is negligible

- Assuming negligible heat losses in piping between collector and the tank

- Assuming negligible losses between the storage tank and the generator.

Where G, (W/m2) is the incident solar radiation intensity; Ac (m2) the area of collectors, τ is the transmissivity coefficient of the glass cover; α is the absorptance of receiver’splate surface; FR is the heat removal factor; Tc,i (K) is the inlet fluid temperature; Ta, (K) is the ambient temperature; and UL,(W/m2/K). is the overall heat transfer coefficients. The useful energy it’s given also by the first thermodynamics law, equation (2).

Where ṁ, (kg/s) is the mass flow rate of collectors and Tc,o, (K) is the outlet fluid temperature. Combining Eqs. (1)–(2), the water outlet temperature of the collectors can be expressed as equation (3):

Equation (3), can be used to estimate the collector area required to provide hot water at specified flow rate and temperature.

Storage tank

The energy balance of the storage tank temperature can express by equation (4):

Where Cpw,s,(kJ/kgK); ṁs, (kg/s) and Ts(K)are the specific heat of water, mass flow rate and temperature of water in the storage tank respectively. Cp,t and ṁt are the specific heat and the mass of the empty tank, respectively. UL(W/m2/K) is the overall heat loss coefficient of the tank and As (m2) is the area of the storage tank. Qg, (kW) is the energy received by the generator in the absorption chiller[7].Assuming negligible heat losses in piping between collector and the tank by guarantee good thermal insulation implies that Q=Qu. Losses between the generator circuit and the storage tank are negligible; the amount of heat which is demanded for driving the refrigeration cycle is obtained by the following equation (5).

Where ṁg is the mass flow rate of water, Tg,i and Tg,o, (K) are the water inlet and outlet temperature of the generator, respectively. The amount of heat Qs (kW), stored in a tank for a working day, when the water tank reaches its maximum temperature, can be expressed by the equation (6).

Ts,max (K) is the water temperature at storage tank. Tf,I is the inlet water temperature entering the tank. At night it is vital to assume that storage tank is cleaned properly for DHW application when air conditioning system is switched off.

Absorption chiller

For the absorption chiller, the COP can be expressed as equation (7), where Qc(kW) is the amount of cooling energy generated by the chiller’s compressor.

Overall thermal model

By substituting equations (4) and (1) into equation (7) integrating the heat transfer processes associated with the solar collector, storage tank, and absorption chiller obtaining the cooling load concerning the systems can be given by equation (8):

This mathematical model allows a wide range of cooling load, Qc, (kW) varying the system design parameters such as the collecting area, mass flow, as well as choosing the appropriate optical parameters according solar technology, to meet the thermal demand chiller Qg(kW). The performance of solar cooling system (COPs) can be given by equation (9). It´s finding by the COP multiplied by η, solar array efficiency [8]:

GENERAL DESCRIPTION OF THE PHOTOVOLTAIC COOLING SYSTEM WITHOUT STORAGE

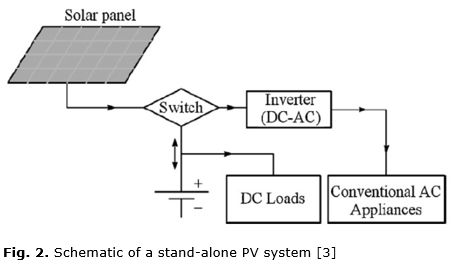

The system is similar to the conventional system HVAC but the energy demand is covered by the electricity obtained by PV modules and if required from the public grid. A PCS without storage typically consists by four basic components: photovoltaic modules, an inverter circuit and a vapor compression AC unit which is shown schematically in figure 2.

Electrical power generation PV array

For the PV cooling system described above, the prediction of PV module performance in terms of electrical power output in the field, is modeled by the expressions presented by Skoplaki and Payvos. The power output of PV array can be calculated from the equation (10) [9].Where Pmax,ref, (W) is the nominal electrical power of photovoltaic generator at under standards conditions (STC), GT(W/ m2) is a solar radiation on tilted plane module GTref, is a solar radiation at STC, equal 1000 W/ m2, γ (ºC-1)is the temperature factor for powerequal to -0.045 for crystalline silicon modules. Tc, (ºC) is the cell temperature, is calculated using the equation (11), presented Evans [10].

The operation cell temperature NOCT employed in equation (11), it is common to use it as an indicator of module temperature. It is an important parameter in module characterization since it is a reference of how the module will work when operating in real conditions. Furthermore, in PV system design and simulation programs, many calculations are based on the determination of module temperature from ambient temperature and NOCT. Tamb (ºC) is the environmental temperature. The traditional linear expression for the PV electrical efficiency is given by equation (12), presented in [11].

In which ηref is the module’s electrical efficiency at the reference temperature Tref equal 25ºC, at solar radiation flux of 1000 W/m2.

FEASIBILITY ANALYSIS

Final total investment costs determine annual capital cost and therefore have a strong influence in the economic and financial values such as payback and cost of primary energy. The payback period is defined as the period of time (i.e. no. of years) required for the return of investment and can be expressed mathematically by equation (13).

Various author ranked the solar cooling technologies according to the cooling generation cost (CGC), expressed in equation (14), [2][12]. CGC takes into account the capital cost of the solar field, the cooling equipment, the thermal storage, the land and the problems of supply–demand mismatch and how performance of the system changes with conditions. It also includes the costs of annual maintenance throughout the life time of the plant embedded in the finance parameter α.

Where Capex is the capital cost [$/kWh cooling capacity], α is the ratio between the capital investment and the annual fixed payments, M is the annual maintenance cost [% of Capex per year], ΣO is the annual operation cost [$/kW cooling capacity], FLH is the usable cooling yield expressed as the number of full load hours per year [h/year].

The economic assumptions are:

- Maintenance is assumed to be constant throughout the life time of the plant (25 year), it is normally provided in the contract as a percentage of Capex. Values between 0.5% and 3% of Capex are reported in the literature for the solar field and the cooling equipment

- Operational cost are mainly dominated by the cost of electricity needed to run the chilled water pump, cooling tower, condenser water pump, and air handling unit (AHU).Since we assume that this demand is met by extra PV cells which price is included in Capex, operational costs are assumed to be zero.

Meteorological data

The global radiation and ambient temperature is shown in figure 3a. Integrating a total available solar energy of 6 967MJ is obtained, corresponding to 6.54 kWh/(m2day). For winter day, figure 3b. The total available energy of 4 653.44 MJ is obtained, corresponding 5.04 kWh/(m2day). Both examples are good agreement whit historical data for Cuba.

Measurements daters for figure 3, were taken outside the building of the meteorological center of Cienfuegos Cuba.

RESULTS AND DISCUSSION

Case study 1: solar-powered absorption cooling system. Energy performance

The building considered in the study is a hotel with 149 rooms available for tourism. The main building has a capacity of one hundred thirty six rooms (136), a block of thirteen (13) cabins located in the pool area. The HVAC systems of the hotel are two water chillers model, CHAWT-1402-AT-BP-RC-100 C1-VT, with a cooling capacity: 404 kW each, 115 Tons of refrigeration (TR) chilled water flow GW-70 m3 / h. Temperature Input / output: 11/6 ° C. The available roof area is 1500 m2 for the installation of solar collectors.

This installation is considered as a transit hotel, so during daylight hours from 10:00 am to 4:00 pm a maximum of 50 TR it´s only need to satisfy their air conditioning needs on the ¨areas nobles¨ circuit that it’s compound of offices, store and administrations departments. To cover the same mixed air conditioning scheme, which incorporates a solar absorption air conditioning to existing conventional HVAC systems is proposed.

For the SACS system, the key elements are: solar collector array: 180 (468 m2) Flat plane collector EURO-20 AR. The absorption chiller: COGENIE LT-5 with a capacity of 176 kW and COP equal to 0.69. The Hot water is driven to the generator side at temperature of 85ºC. This SACS was analyzed under the following operating system: At 08:30 am when the sunshine on the roof reaches about 200-250 W/m2, the primary circuit pump is switched on and circulate water in a closed circuit, made by the solar field and heat storage tank, gradually raising the temperature of the fluid until it´s reaches 80ºC. Then hot water is driven to the generator circuit. The system doesn’t use auxiliary heating system. The main requirement is that the absorption chiller should be operational at 10:00 am at 60% of its cooling capacity. The system operates until 16:00 hours (minimum requirement, could be more, depending on environmental conditions), when comes into operation the conventional system, because the thermal load in the hotel increases. When it’s not needed to heat or cool the water or is sent through a heat exchanger for DHW, raising water it to its operating temperature of 60ºC. The heat delivered to the absorption chiller can be calculated by integrating the product of the flow rate through the chiller with the temperature drop across the generator. The flow rate through the chiller is constant. The operation of the chiller is summarized in figure 4a), for a typical summer day and a typical winter day it´s show in figure 4b). In the figure plot shows inlet/outlet temperature of chilled water (CHW), hot water (HW) – left axis, and the coefficient of performance of the chiller (COP)-right axis.

In a typical summer day the chiller begins operating at 10:00 am, when 39 800 l of water at the set point of 88ºC have been accumulated. Operation continues for over 6 hours, during this period of time a 7 592.39 MJ of hot water from the tank is supplied to the chiller. Return chilled water from the cold air handlers enters the chiller and is cooled approximately 4.5-6.7ºC in standards conditions, the chilled water flow rate is constant. A total chilled water production of 3 977.9 MJ, corresponding to an average chiller COP of 0.53 is obtained, slightly lower than the value that can be calculated using the manufacturer´s technical literature. The instantaneous COP plotted oscillates between 0.45 and 0.75, the low values corresponding to peaks in the heat delivered at the generator circuit.

In a typical winter day, figure 4b) the chiller begins operating at 11:00 am, and the operation continues for over 5 hours, the total heat energy delivered is 3 110.39 MJ and the total chilled water production of 5 000.39 MJ. The instantaneous COP oscillates between 0.5 -0.8, corresponding to an average COP of 0.62 a better performance than in summer day. In resume for a whole year the SACS supplies the cooling requirements of the hotel during 6 hours. The overall system predict 300 303 kWh of cooling per year.

Case study 2: Photovoltaic cooling system. Energy performance.The proposed system was implemented for same facilities. The cooling demand of the building could be covered during 11:00 am until 4:00 pm by a chiller CHAMT-601 with 159 kW cooling capacities. For this case it’s needed a photovoltaic solar arrays of 454 PV modules JAP6 60-245/3BB750 m2 for produce enough energy to cover the demand from 10:00 am to 4:00 pm, and 5 inverters SMA TRIPOWER 17 000 TL. Figure 5, show the theoretical electric power and electrical efficiency of the PV array evaluated by using equation (10) and equation (12).

In the case of summer conditions, the chiller CHAMT-60 requires 54.70 kW of compressor input power to deliver 159.20 kW of unit capacity. These working conditions are reached from 9:30 a.m. until 5:00 pm. The energy delivered by the photovoltaic array is obtained by integrating the area under the curve shown in the previous figure. It´s predicts that this system delivers a total of 619 kWh per day during a typical summer day and 428 kWh in one typical winter day. This will also allow delivering to the local grid a total of 288 kWh and 154 kWh, respectively. The PCS system supplies the cooling requirements of the hotel during 6 hours. The overall system predict 235 356 kWh of cooling per year.

FEASIBILITY COMPARISON OF BOTH SYSTEMS:

The cost of a solar cooling installation is a direct function of the design of the entire system, the weather conditions of the region and the choice of technology constantly developing by changing the relationship between the surface of solar panels and air conditioning load or volume storage. In the paper the investment costs are the sums of all the component of each system. The cost of the main components is calculated by multiplying the size of each component by specific cost shown in table 1. No funding subsidies are included.

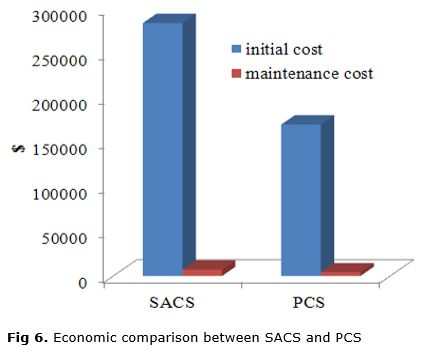

Compared to conventional HVAC equipment, these systems are expensive. According to several case studies analyzed, the investment costs of both technologies in a high percentage exceed operational costs as shown in figure 6. It seems an increase of 40% of SACS regarding the PCS. Due to the complexity of the scheme SACS system some components like additional pumps, cooling towers, thermal collectors, storage tanks and relevant controllers are pricey.

Considering the energy performance of both schemes plus the costs of these facilities apply the expression 14 obtained the CGC of SACS and PCS are 13.7 ¢/kWh and 0.10. ¢/kWh respectively. The result also showed that SACS has slightly longer payback period compared to PCS estimated to be 10 years and 6 years in that order. For the SACS systems the savings means 232.7 Tons CO2 reductions of carbon emissions, equivalent also to remove 42 cars out of roads or savings 541.11 barrels of crude oil. For the PCS systems, included the energy delivered to the local grid. Estimated saving represents 307.4 Tons CO2 the reduction of carbon emissions, removing 56 cars out of roads and savings 714 barrels of crude oil.

CONCLUSION

In this paper, the energy and environmental performance of a SACS system and PSC system were evaluated and both technologies were compared, considering mathematical models that describe these systems. In summary, the outcomes of this paper are outlined below:

- SACS system predicts 300 303 kWh/year cooling. On a typical summer day the system could work a little more than 7 hours, when solar field will reach peak temperatures between 95ºC and 100ºC. The instantaneous COP oscillates between 0.45 and 0.75 and the low values will correspond to peaks in the heat delivered at the generator circuit. On a typical winter day, the COP will improve oscillates between 0.5 -0.8; but the meteorological conditions will allow the system to work an average of 5 hours. This configurations offer the advantage of the availability of hot water for HWD.

- PCS system predicts 235 356 kWh/year cooling. The energy delivered by the photovoltaic array will be 619 kWh on a typical summer day and 428 kWh in one typical winter day. This will also permit delivering to the local grid a total of 288 kWh and 154 kWh respectively, the system could work an average of 6 hours. The COPs range from 0.4-0.6, low values it´s caused by low efficiency performance of PV array.

- Economic results show that the photovoltaic cooling system is favorable in comparison with the SACS. An exhaustive sensitive analysis show a strong influence of initial investment cost on the payback and in the CGC. But energetic comparison indicates that SACS has more thermal applications.

RECOMMENDATIONS

- It’s convenient the study of the use of solar photovoltaic–thermal (PVT) collectors. It’s a promising technology that was receiving wide attention. Cooling of the PV modules by the heat transfer fluid flowing through the PVT collector then leads to an increase in the overall energy collection and conversion efficiencies of the system. Also with this collector is obtained thermal energy for hot water applications.

- A reduction of this cost is necessary to increase the feasibility of solar driven cooling systems. Further comprehensive, prompt research and development activities are necessary in Cuba in order to promote this kind of air conditioning hybrid system schemes.

REFERENCIAS

1. SRINIVASA KR, R. Low cost solar cooling system. International journal of Engineering and innovative technology (IJEIT). 2013;4. ISSN 2277-3754.

2. MOKHTAR MA, M.; BRAUNIGER, S.; AFSHARI, A.; SGOURIDIS, S.; ARMSTRONG, P.; CHIESA, M. Systematic comprehensive techno-economic assessment of solar cooling technologies using location-specific climate data. Applied energy. 2010;87:3766-78. ISSN 0306-2619.

3. OTANICAR TT, R PHELAN P. Prospects for solar cooling-An economic and environmental assessment. Solar Energy. 2012;86:1287-99. ISSN 0038-092X.

4. Zhai XQQ, M Li Y, Wang RZ. A review for research and new design options of solar absorption cooling systems. Renewable and Sustainable Energy Reviews. 2011;15:4416-23. ISSN 1364-0321.

[5. GHAIT FA. Energy analyses of an integrated solar powered heating and cooling systems in UAE. Energy and Buildings. 2014;70:117-26. ISSN 0378-7788.

6. DUFFIE JAB. Solar Engineering of Thermal Processes. 3a ed. USA: John Wiley & Sons, Inc.; 2006. ISBN 978-0-470-87366-3. Disponible en: http://refhub.elservier.com/S0378-778(13)00721-4/sbref008.

7. J DARKWA J. Theoretical and practical analysis of an inte-grated solar hot water powered absorption cooling system. Energy. 2012;39:395-402. ISSN 0360-5442.

[8. DÍAZ. Y M, et al. Análisis energético de un sistema híbrido de producción de frío. Ingeniería Energética. 2015;36:38-49. ISSN 1815-5901.

9. Skoplaki E, et al. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Solar Energy 2009; 83:614-24. ISSN 0038-092X. DOI

10. Evans DL, et al. Cost studies on terrestrial photovoltaic power systems with sunlight concentration. Solar Energy. 1977;19:255-62. ISSN 0038-092X.

11. JAN A. New absorption chiller and control strategy for the solar assisted cooling system at the German Federal environment agency. International Journal of Refrigeration. 2014;39:48-56. ISSN 0140-7007.

12. EICKER U, et al. Economic evaluation of solar thermal and photovoltaic coolingsystems through simulation: An analysis in three different cities in Europe. Energy and Buildings. 2014;70:207-23. ISSN 0378-7788.

Recibido: Mayo 2015

Aprobado: Septiembre 2015

Yamile Díaz Torres. Eng in Mechanical Engineering in 2004, the Bs. Eng in Industrial engineering in 2011, and the MS degree in Energy Efficiency in 2013, a professor at the Centre for Studies of Energy and Environment (CEEMA) of the Cienfuegos University and a PhD student. e-mail: ydtorres@ucf.edu.cu