Mi SciELO

Servicios Personalizados

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Cooperativismo y Desarrollo

versión On-line ISSN 2310-340X

Coodes vol.10 no.1 Pinar del Río ene.-abr. 2022 Epub 30-Abr-2022

Original article

The value chain as a management tool for the production of consumer rice

1 Empresa Agroindustrial de Granos "Los Palacios". Pinar del Río, Cuba.

2 Universidad de Pinar del Río "Hermanos Saíz Montes de Oca". Facultad de Ciencias Económicas. Departamento de Contabilidad y Finanzas. Pinar del Río, Cuba.

Given the accelerated changes that are taking place in world economies, the Agroindustrial Grain Enterprise "Los Palacios" is forced to use innovative tools that allow it to compete in any market. Hence, Strategic Cost Management is used as an effective tool, together with the application of new cost trends. The diagnosis carried out through surveys, interviews, documentary analysis and observation in certain areas of the enterprise showed that in the production of consumer rice there is no Strategic Cost Management, based on well-founded strategic elements, which leaves the enterprise's personnel exposed to making inadequate future strategic decisions. Based on this, the general objective is defined as follows: to apply a Strategic Cost Management methodology, elaborating the value map in the production of consumer rice as an important element in the determination of cost management in the different production processes of consumer rice. With the implementation of the methodology, a better identification of the links in the value chain was obtained, thus determining those that create value to the product. The work is novel because the new enterprise management system proposed for the production of domestic consumer rice seeks to increase competitiveness, turning it into an improved decision-making system.

Key words: cost; strategy; management; value

Introduction

Over the years, humanity in general has experienced a significant advance in science and technology, which has led a considerable number of researchers to focus on the search for alternatives that contribute to reducing costs, generating value in products and thus increasing profits. This allowed enterprises to stay in the market for a longer period of time and thus be more competent in terms of management.

In different authors, it is common to find references about management, which is defined as the action and effect of managing and administering in a more specific way; a management is a diligence focused on obtaining some benefit through the control and improvement of processes (Mora Pisco et al., 2016).

Strategic cost management consists of looking at the different activities that make up the enterprise's value chain from a global and continuous perspective, which serves to route the enterprise's internal capabilities and project them onto the external environment, procuring information for the prolonged application of business activities (Mallo Rodríguez et al., 2018).

Hence, the value chain is an important form of analysis of the enterprise's activity, but it is, first and foremost, a guide for management; it consists of breaking down the enterprise into its constituent activities, seeking in those that generate value the competitive advantages required, managing to develop them more efficiently and at lower costs, while improving processes and the flow of information and goods.

Rivas et al. (2018) refer that with the application of the value chain it will be possible to optimize the productive process and increase the profitability of the enterprise from the reduction of costs. It should be noted that a value chain will always be sensitive to customer needs, taking into account product quality, delivery time and information flow as key factors.

According to Batista and Estupiñán (2020), enterprises are immersed in highly competitive and globalized environments, so they must begin to worry about the need for good enterprise management, as they are required to be more competitive every day; this need generates the adaptation of information, giving rise to the management of production costs.

With this approach, production costs through the use of cost accounting analyze the interior of the enterprise, presenting information for decision making, while management expands its analysis by taking into consideration the internal and external efficiency of the enterprise, in order to project more convenient results to the market in which they are developed. Since, as Mendoza, Jaramillo and López point out (Mendoza Fernández et al., 2020, p. 97) "the enterprise is a social agent and its actions as well as its omissions have an important impact on society".

Cuba, as a country living in unique conditions, is no stranger to these new management trends. As proof of this, it is constantly updating its economic model in order to achieve a more efficient and sustainable national economy.

In this sense, the responsibility of the Agroindustrial Grain Enterprise (EAIG in Spanish) "Los Palacios" is to plan and carry out the production of rice for consumption which final destination is to satisfy the demand of the different clients that participate as part of the productive chain, guaranteeing efficiently in its productive process the use of material and financial resources and labor force. It also determines the relevant importance of cost management in each of the production processes as a fundamental tool in decision making in the strategic direction as part of the production process in the value chain of consumer rice.

The enterprise today faces the challenge of assimilating strong and continuous changes, not only of the environment, but also social, technological, new regularizations and legislations in all the monetary reordering of the country, in order to increase the substitution of imports to satisfy the demand of a vital product such as rice consumption; therefore, it is necessary to make quick decisions and adapt to this changing and complex world in constant evolution of the market. Therefore, it is immersed in a process of constant institutional improvement in order to meet the needs of customers and increase efficiency in its actions as part of the production chain, establishing a management policy that promotes the commitment of management and workers with a focus on processes, aimed at acting on the quality of the final product throughout its production process, so it implements an integrated quality management system.

To guarantee this policy, the enterprise management has the necessary resources to ensure the correct management of quality, environment, human capital, occupational health and safety and technological innovation; it promotes the deployment of integrated objectives to all activities and processes and establishes as a permanent work objective of the center the implementation, maintenance and continuous improvement of the integrated management system in the value chain of rice consumption.

Taking into account the above and the new demands of the economic reality, the enterprise sees the need to rectify and determine a new vision in the cost management system, determining to improve the value chain in the production of consumer rice as a new novel element as there was no previous reference of it. Hence, the objective of this research is aimed at applying a methodology of Strategic Cost Management, developing the value map in the production of consumer rice as an important element in determining the cost management in the different production processes of consumer rice.

Materials and methods

The research was framed in one of the results foreseen in the project of the Accounting and Finance Department of the "Hermanos Saíz Montes de Oca" University in Pinar del Río: "Improvement of the Accounting and Financial Management in the enterprises of the territory", focused on the increase of the economic management in the Pinar del Río territory, specifically in the EAIG "Los Palacios".

Taking into account the particularities of this research, together with the characterization of the entity under study and the special characteristics of the value chains, the objective and scope of the study were first defined, then the information needs were determined and a list of these needs was drawn up, then the sources of information to be used were defined, then the instruments and templates were designed for collecting, processing and analyzing the information obtained, and finally, the report was prepared and presented. The following methods and techniques were used:

The diagnostic process was extended to all areas and structures of the enterprise, using the empirical method of scientific observation, through interviews and direct inspection of the physical areas, including: the directors of agricultural and industrial production; specialists in plant health, soils and fertilizers, irrigation, agricultural production and seed; quality specialist and marketing specialist; specialists in accounting and costs; as well as other members of the board of directors.

The analysis of documents that support the necessary information, based on the resolutions in force for this productive sector.

Field observation or inspection was also used to verify the agricultural productive areas (rice fields), productive areas of the industrial units (drying and milling), technological equipment of the industry, equipment of the agricultural machinery and evaluation of the performance of the human capital.

The analysis and synthesis that made it possible to decompose the theoretical and practical knowledge on the value chain of consumed rice and to elaborate the suggested modifications.

The statistical method was also used through descriptive statistical techniques and the use of tables that concentrate the data provided by the entity under study.

The information obtained in the diagnosis allowed to identify certain information needs, among which are the structure by areas and their strategic objectives, the behavior of the production activity, the level of specialization in food technologies, the production infrastructure, the standards and procedures that guarantee the quality of the product, relations with suppliers and contracted demand, the list of clients and demand for contracted production, as well as potential clients.

Results and discussion

In order to carry out this research, the activities that make up the value chain and the action plans to be applied to them are defined at the beginning of the period; from that moment on, the extent to which the tasks foreseen to be developed in the competitive environment have been fulfilled is assessed, mainly in fundamental issues such as:

The value chain of the business units or enterprise

Enterprise unit or enterprise-competitor relations

The total value chain

The value chain management analysis began with a reference to those activities that add value for the client; it also includes a reference to the process map and the calculation of the efficiency with which the strategic productive activity is developed. Finally, a comprehensive analysis of the structure of the value chain is made, according to possible classifications of the activities included in it, and then its importance as a tool for strategy formation is highlighted.

Each of the actions carried out is linked to the leaders and labor collectives in order to commit them to meet the proposed objectives, the defined strategies and, in general, to be able to measure the strategic performance achieved.

Therefore, the research reflects the result of the implementation of the value chain methodology referred to above in one activity of the EAIG "Los Palacios" (production of rice for consumption), which can be generalized to the rest of the activities until the total of the same is reached; this makes it possible to specify the way and the magnitude in which each of the activities influence the overall results achieved, having, in turn, more precise and detailed information on each process, which contributes to improve control, performance evaluation and decision making.

To do this, it was begun by analyzing different theoretical criteria of what a value chain is, starting with Porter (1985), who was the first to popularize it. From his perspective, value chains are considered theoretical models or models to be followed in which the processes that an enterprise and/or industry must carry out to generate value for the end customer are written in detail and systematically.

This criterion is studied and enriched by Díaz (2015), who considers the value chain as a powerful tool for the analysis of strategic planning, which main objective is to maximize value creation while minimizing costs; hence, an enterprise's value chain and the way they perform their individual activities are a reflection of their history, their strategy and their approach to implementing the strategy itself.

While García, Juca and Juca (2016) consider that the value chain is the set of all the activities necessary to achieve a product or services that result in obtaining a significant value at the end of the product, resulting in a great benefit for the producer and consumer.

However, Alvarado and Oddone (2017) emphasize the four essential elements that must be analyzed in an enterprise when it comes to the value chain:

The links and the actors that compose it (includes the steps of elaboration and delivery of a product or service)

Articulations between links and actors (important for smooth operation and allows for the disaggregation of activities)

Appropriation of added value

Chain governance (necessary step to determine the procedures to be adapted by the chain's actors)

All these elements are further developed by Guzmán and Chire (2019) and in this regard they state that the value chain determines the competitive advantages through a method to generate added value, considering the cost and value generators that allow every enterprise to act on the elements that need to be strengthened.

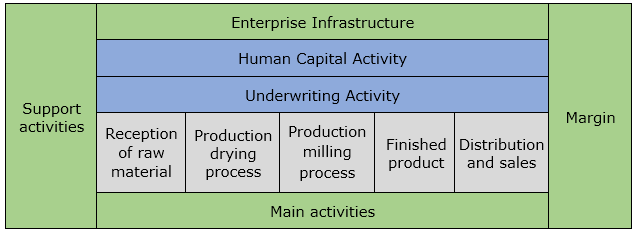

For their part, Linzán, Ruiz and Murillo (2021, p. 19) point out that all these previous researches have focused on defining the value chain as a basic tool or strategic analysis tool that helps an enterprise to establish its competitive advantages, being a means of desegregation or systematic that recognizes all the actions carried out by a company. It is therefore necessary to "understand each enterprise as a set of activities divided into two large groups: primary, those that determine value to the company, and support, which normally help in all the enterprise's activities".

In addition, they consider it appropriate to define the value chain as: "theoretical models with a wide variety of activities where value is generated for the final customer, in all stages of the development of a product or service of an enterprise " (Linzán Saltos et al., 2021, p. 19).

The various definitions analyzed above show the complexity of assuming a single definition of value chain, since in some cases they have been considered as instruments of analysis; in other cases, as tools to facilitate dialogue and the creation of commitments between actors and in the definition of public policies to improve competitiveness; however, Ferro et al. (2020) state that in most studies they have been used as a tool for the preparation of comprehensive diagnoses of an agrifood product. This sector has all kinds of products, including cereals, and rice stands out as one of the main ones in this variety.

The research is focused on this product and no other due to its economic and social importance which, according to Bermúdez Espinoza, Murillo Mora and Ruiz Cedeño (2020) is that although it is considered a product with volatile characteristics in the market due to price instability, it is nevertheless the staple food of at least half of the world's population.

Once the above definitions of the value chain in general and the rice product in particular have been analyzed, the criterion of Bermúdez Espinoza and Murillo Mora (2019) consider that the rice value chain is nothing more than a series of activities and processes required for this cereal to reach the final consumer and in which some stakeholders participate, hence its importance within the competitive market.

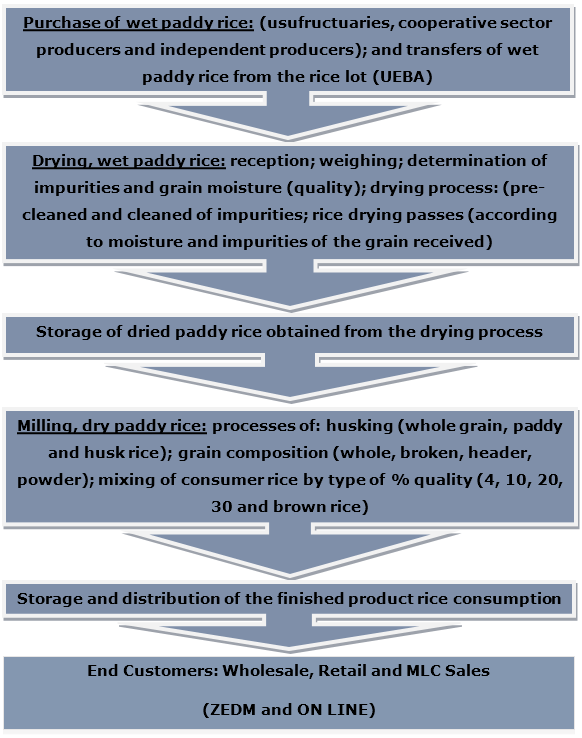

In the specific case of Cuba, the value chain of the consumer rice product is structured by the interaction of three agents that define the links: agricultural production, rice plots, usufructuaries and cooperatives (primary link), industrial Base Enterprise Units (UEB in Spanish) that process rice as a fundamental raw material, where the rice drying and milling process is carried out separately (industrial link) and finally its commercialization (marketing link), which specific processes provide added value to the product, that in this case, the product is wet paddy rice, which is used to produce the product in its different assortments, according to the composition of whole and broken grains, that is, by quality (4%, 10%, 20%, 20%, 30% and brown rice) and those by-products that accompany in the process (powder, header and broken rice), which reach the final consumer.

The following is a proposal of the process flow of the consumer rice product, starting with the primary link, which are the agricultural producers: rice lots, usufructuaries and cooperatives, until reaching the final consumer.

Wet paddy rice production

Soil preparation: (dike breaking, breaking, crossing, leveling of soils)

Sowing: (fertilization, sowing and seed cover; marking and raising of dyke)

Insurance policy payment expense

Cultural care: irrigation, fertilization, herbicide and fungicide applications (as needed)

Services received: irrigation, aviation, runway, transportation, roads, maintenance and construction of irrigation systems

Harvesting wet paddy rice

Transportation of wet paddy rice

Dry paddy rice production

Receipt and weighing of wet paddy rice: Received by transfers from agricultural UEBs, purchases from the cooperative sector and other eventual producers; determination of impurities and grain moisture (quality process)

Storage of the wet paddy rice received (forming of the drying lot)

Drying process: (pre-cleaning and cleaning of impurities; wet paddy rice drying passes (according to moisture and impurities of the grain received)

Storage of dry paddy rice obtained from the drying process (dry paddy rice lot)

Resting of dry paddy rice before milling in storage silos

Rice production consumption

Dried paddy rice entering the milling area

Cleaning pass through dry paddy rice pre-cleaning machines

Weighing of dry paddy rice after precleaning

Filling of sheller feed box

Dry paddy rice husking process in: (brown grains, paddy and husk rice)

Rice separation process by grain composition into whole and broken grains (whole, broken, header, powder)

Polishing and grain separation process

Mixing process of rice consumption by type of quality % (4, 10, 20 and 30); or brown rice

Packaging process

Storage of the product rice consumption

Delivery of the rice product to customers as contracted

Transportation and after-sales customer service

In addition to the above, it is essential to keep in mind in the drying and milling process the consumption norms of the fundamental inputs necessary to obtain a ton of consumed rice, which are present in the corresponding process (Table 1).

Table 1 Consumption norms for one ton of rice consumption

| Index | U/M | Quantity |

|---|---|---|

| Energy Consumption Electricity | KW/T | |

| Diesel Consumption | L/T | |

| Energy Consumption Electricity | KW/T | |

| Sacks | One | 23.5 |

| Descaling Rollers | Rod./T | 0.014 |

Source: Prepared by the authors

The areas and times required for each activity were also defined (Table 2).

Table 2 Required areas and times according to activities

| Activities | Areas | Weather |

|---|---|---|

| Agricultural production of wet paddy rice | Rice lots | 5 to 6 months |

| Receipt and weighing of wet paddy rice: received by transfer from agricultural UEBs, purchases from the cooperative sector and other eventual producers; determination of impurities and grain moisture (quality process) | Drying | 1 hour |

| Storage of the wet paddy rice received (forming of the drying lot) | Drying | 16 hours |

| Drying process: (pre-cleaning and cleaning of impurities; wet paddy rice drying passes (according to moisture and impurities of the grain received) | Drying | 5 days |

| Storage of dry paddy rice obtained from the drying process (dry paddy rice lot) | Silos | 4 hours |

| Resting of dry paddy rice before milling in storage silos | Silos | minimum: 30 days |

| Dried paddy rice entering the milling area | Milling | constant |

| Cleaning pass through the pre-cleaning machines | Milling | constant |

| Weighing of rice after pre cleaning | Milling | constant |

| Filling of the husker feed box | Milling | 2 hours |

| Dry paddy rice husking process in: (brown grains, paddy rice and husk) | Milling | constant |

| Process of separating rice by grain composition into whole and broken grains (whole, broken, header, powder) | Milling | constant |

| Polishing and grain separation process | Milling | constant |

| Mixing process of rice consumption by type of quality % (4, 10, 20 and 30); or brown rice | Milling | 6 hours |

| Packaging process | Milling | 30 ton/hours (3 times) |

| Storage of the product rice consumption | Warehouse | 8 hours |

| Delivery of the product rice consumption to customers as contracted; (sales or own consumption) | Warehouse | According to customer's request |

| Transportation and after-sales service to customers | ||

Source: Prepared by the authors

As a result, the main activities that generate value in the production process were determined:

Purchase of wet paddy rice from farmers and rice lot transfers

Activities in the drying process: reception and weighing; pre-cleaning and cleaning of impurities; drying passes of wet paddy rice (according to moisture and impurities of the grain received) and storage costs (silos) of the dry paddy rice obtained

Activities in the milling process: entry of dry paddy rice into the area for husking, separation by grain composition into whole and broken grains, grain polishing and mixing by product quality

Activity of the final product packaging process rice consumption

Storage of the finished product in the process of aging, resting and loading for transport at the time of sale

They do not generate value:

Transportation service for the sale of the product from the producer's warehouse to the wholesaler or retailer's warehouse

After-sales services

Taxes, fees and contributions

Security and protection costs for custodians in the unit

Maintenance services for occasional breakdowns during the industrial production process

Expenses due to internal and external interruptions outside the production process

Losses and shortages of stored material goods, as well as shrinkage and deterioration in excess of the standards established in the production process, whether attributable to specific culprits or assumed by the entity, as well as the surplus of such goods

A new value chain is proposed to the EAIG based on its main or primary activities for better production and, in turn, a better competitive advantage in the market (Table 3).

Table 3 Main or primary activities

| Inbound logistics | Operations | Outbound logistics | Distribution and sales management |

|---|---|---|---|

| Receipt of raw materials and production services from suppliers | Planting, harvesting and transportation | Movement to the warehouse | Product distribution |

| Storage | Drying and storage process | Product storage | |

| Own production services | Husking and blending of whole and split grains | ||

| Production | Packaging according to grain mix | ||

| Quality control |

Source: Prepared by the authors

This value chain can be summarized by showing four key processes:

Reception of raw material

Production drying and milling process

Finished product

Distribution and sales process

Thus, the entity's value chain would be made up as follows (Fig. 1).

Finally, the analysis of the links that make up the total value chain of the rice product shows the total value chain for rice consumption in the vertical direction in figure 2.

Advantages and impacts of the application of the methodology

The present research responds to the application of a methodology that has been generalized in several enterprises in the province of Pinar del Río, due to the advantages of its implementation, among which the following stand out:

Determination and elaboration of the value chain map for the production of rice for consumption

Improvement of the calculation of the total unit cost in the different stages that generate value in the chain in the total production of rice consumption in the enterprise and the agricultural and industrial UEBs

Improvement of the links that make up the total value chain in the production of consumer rice

Improvement of the accounting transfer between the cost centers of the production accounts in both agricultural and industrial processes that are part of the value chain

Definition of direct and associated cost centers; identification of direct, indirect and financial expenses for each cost center in the different stages of the value chain of the production of consumed rice

Increased efficiency by analyzing the costs of inputs, labor and production services that are accounted for at each stage of the value chain from product to final destination

Greater competitive advantage in relation to other periods, by reducing the cost per ton of the rice product by 646.47 pesos in 2020 compared to 2019, which in value terms means 1,282,919.72 pesos

A rationalization of the workforce in the value chain processes and an impact on the payment systems applied at each stage is achieved, obtaining a positive evaluation of the results in the expenses and income of each one of them in the chain that integrates it

Correct preparation of cost sheets for the rice product at the different defined stages of the agricultural production process, drying and milling, once the value chain has been determined, thus achieving better projection of expense and income budgets

Preparation of cost sheets for the production of wet paddy rice for the different technologies applied in both the cold and spring rice seasons; and in turn by production sectors (state and cooperative)

Positive impact on the evaluation of the real economic-productive analysis of the expense budgets in the cost centers of the value chain in rice production in its different stages

An economic, technological, ecological and environmental impact is achieved by taking into account the technical instructions of the crop with its correct application, achieving an integrated management in the use of resources, pest and disease management, also making an adequate use of biological means throughout the value chain

Contributes to improving internal control in the use of inputs and production services linked to the different stages of the rice production process in the value chain of the product

Allows the management of the entity and the UEBs to make timely economic and financial decisions, achieving efficient cost reductions for different concepts in the value chain in the production of consumer rice

Maximizing the use of rice by-products (harvest residues, dust, husks, husks, husks, fourth grain) as a source of cost reduction in the value chain by more than five percent and increasing income from sales

Identification of a new product in the value chain based on the broken rice by-product (rice flour), generating income of 3,974,376 pesos during the period

The enterprise today faces the challenge of assimilating strong and continuous changes, not only of the environment, but also social, technological, new regularizations and legislations in all the monetary reordering of the country, which makes it necessary to make quick decisions and adapt to the evolution of the market. Hence the need to insert the analysis of the value chain management in the production of consumer rice, allowing to define the main and support activities of the company, its value map according to the authors of the applied methodology, as well as its position in relation to the total chain in its vertical analysis.

From this point of view, the Methodology for the Analysis of Strategic Management of the value chain that is applied, allows the EAIG "Los Palacios" to carry out superior strategies to discover new competitive advantages with respect to the rest of the rice companies in the country, since it has a superior tool for the business decision-making process. In addition, its application for a year and a half has allowed to prove the advantages of this to the management of the entity, by having a procedure for the restructuring of its flow of activities, reducing work times in each process, achieving a human improvement, all without delaying the delivery time to the customer, which makes it more satisfied and allows renegotiating sales prices based on the quality of the product, which increased its final performance.

Referencias bibliográficas

Alvarado, J., & Oddone, N. (2017). Fortalecimiento de la cadena de valor de turismo en Pedernales (República Dominicana). En Fortalecimiento de cadenas de valor rurales (pp. 243-292). Comisión Económica para América Latina y el Caribe. https://repositorio.cepal.org/handle/11362/42469 [ Links ]

Batista Hernández, N., & Estupiñán Ricardo, J. (2020). Gestión Empresarial y Posmodernidad. Indo American Books. [ Links ]

Bermúdez Espinoza, L. E., & Murillo Mora, M. K. (2019). Análisis de la cadena de valor en el consumo de arroz para Manabí. Revista Caribeña de Ciencias Sociales, junio. https://www.eumed.net/rev/caribe/2019/06/consumo-arroz-ecuador.html [ Links ]

Bermúdez Espinoza, L. E., Murillo Mora, M. K., & Ruiz Cedeño, S. del M. (2020). Actores de la cadena de valor del arroz en Manabí. Un estudio documental. Polo del Conocimiento, 5(8), 743. https://doi.org/10.23857/pc.v5i8.1621 [ Links ]

Díaz Cáceres, N. (2015). La creación de valor compartido: Estrategia de sostenibilidad y desarrollo empresarial. Cultura Latinoamericana, 22(2), 207-230. https://editorial.ucatolica.edu.co/index.php/RevClat/article/view/1629 [ Links ]

Ferro Valdés, E. M., Martínez Maqueira, Y., Gigato Toledo, A., Castro Barrio, A. M., & Velázquez Toledo, N. (2020). Análisis de la cadena de producción de maíz en el Valle San Andrés, La Palma. Revista ECOVIDA, 10(1), 91-108. https://revistaecovida.upr.edu.cu/index.php/ecovida/article/view/190 [ Links ]

García Saltos, M. B., Juca Maldonado, F., & Juca Maldonado, O. M. (2016). Estudio de los eslabones de la cadena de valor del banano en la provincia de El Oro. Universidad y Sociedad, 8(3 (E)). https://rus.ucf.edu.cu/index.php/rus/article/view/411 [ Links ]

Guzmán, J. H., & Chire Fajardo, G. C. (2019). Evaluación de la cadena de valor del cacao (Theobroma cacao l.) peruano. Enfoque UTE, 10(1), 97-116. https://doi.org/10.29019/enfoqueute.v10n1.339 [ Links ]

Linzán Saltos, L. L., Ruiz Cedeño, S. del M., & Murillo Mora, M. K. (2021). Caracterización de la cadena de valor del cacao en Manabí y sus mejoras. Mikarimin. Revista Científica Multidisciplinaria, 7(3), 17-26. http://45.238.216.13/ojs/index.php/mikarimin/article/view/2587 [ Links ]

Mallo Rodríguez, C., Gago Areces, M., & Meljem Enríquez de Rivera, S. (2018). Contabilidad de costos y estratégica de gestión. Garceta. https://dialnet.unirioja.es/servlet/libro?codigo=712505 [ Links ]

Mendoza Fernández, D. L., Jaramillo Acosta, M. C., & López Juvinao, D. D. (2020). Responsabilidad social de la Universidad de La Guajira respecto a las comunidades indígenas. Revista de ciencias sociales, 26(2), 95-106. https://doi.org/10.31876/rcs.v26i2.32426 [ Links ]

Mora Pisco, L. L., Duran Vasco, M. E., & Zambrano Loor, J. G. (2016). Consideraciones actuales sobre gestión empresarial. Dominio de las Ciencias, 2(4), 511-520. https://dominiodelasciencias.com/ojs/index.php/es/article/view/276 [ Links ]

Porter, M. E. (1985). Competitive advantage: Creating and sustaining superior performance. The Free Press. [ Links ]

Rivas García, Y., Reyes Ávila, I. R., Arzuaga Arjora, A., & Vázquez Betancourt, P. (2018). Construcción de la cadena de valor genérica en la unidad empresarial de base "Cárnico Bayamo". Provincia Granma, Cuba. Observatorio de La Economía Latinoamericana, septiembre. https://www.eumed.net/rev/oel/2018/09/cadena-valor-generica.html [ Links ]

Received: February 10, 2022; Accepted: March 18, 2022

texto en

texto en