Introduction

The present work presents a novel treatment of biomass, in order to obtain sugars mainly for ethanol production. Hydrothermal treatment uses only water to pre-treat straw and break the crystallinity of biomass to obtain sugars for fermentation. It was proved possible to use such treatment for sugar production. Enzymatic hydrolysis was very much enhanced after hydrothermal treatment of rice straw, with the action of enzymes facilitated to break cellulose into smaller carbohydrates.

The search for alternatives to fossil fuels has had the attention of researchers, governmental institutions, among others. The discovery and usage of alternative sources as substitutes for fossil matrices is an emerging topic of debate.1 The two main biofuels used in Brazil are ethanol and biodiesel. Ethanol is mainly obtained from sugar cane, whereas biodiesel is produced from vegetable oils (mainly soy oil) or animal fat.2) An alternative for the obtention of biofuels would be the use of agroindustrial waste and other lignocellulosic raw material, including peels, straws and other parts of plants usually disposed. These can be used for the production of second-generation biofuel, mainly cellulosic ethanol or EtOH 2G.3

One of the agroindustrial wastes with potential use for the production of EtOH 2G is the rice straw that remains from agricultural production. It is estimated that for each kg of grains produced, one kg of straw is obtained. Worldwide, this represents between 650 and 975 million tons of straw per year.4 Rice straw is composed of about 60 % cellulose and hemicellulose.5

Hydrothermal pretreatment is widely used to facilitate the extraction of reducing sugars. This treatment consists in the use of saturated vapor, which causes the breakage of the enclosure of hemicellulose and lignin. This facilitates the access of water to the cellulose matrix, favoring the action of enzymes and the release of reducing sugars.5-6

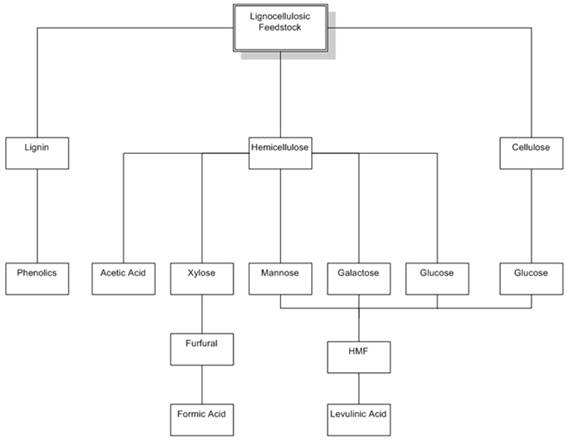

Hydrothermal treatment under pressure favors the hydration of the cellulose structure, dissolving hemicellulose and lignin. Treatments at about 200 °C can release organic acids from hemicellulose. This type of treatment does not require the addition of any chemical compound, enabling the formation of reactive cellulose fibers and the recovery of pentoses. It can also produce a small fraction of the products of lignin degradation with inhibitive potential, such as furfural, 5-(hydroxymethyl) furfural (5-HMF), acetic acid, formic acid and levulinic acid.7,8,9

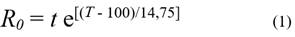

The severity of hydrothermal treatment (Log R0) was calculated using equation (1), suggested by Overend et al..10) The severity factor R0 results from the combination of pretreatment temperature and time. High R0 values can indicate production of reducing sugars (RS) and formation of fermentation inhibitors. The inhibitors and products obtained from feedstock treatment are presented in figure 1.

Where:

t: the time of reaction in minutes

T: treatment temperature in °C

Yu et al. 6 examined efficiency and proposed two experimental designs in order to observe the behavior of: (i) hydrothermal pretreatment, in order to facilitate enzymatic attack in the hydrolysis stage, and (ii) enzymatic hydrolysis, so as to have the best conditions to obtain reducing sugars from pretreated rice straw.

Hence, the objective of this study is to determine the efficiency of a process that combines hydrothermal pretreatment and enzymatic hydrolysis for the obtention of reducing sugars from rice straw.

Materials and methods

Raw material preparation

Rice straw (Oryza sativa, cultivar BRS AG) was provided by Embrapa Terras Baixas (Pelotas, Brazil), 2016 season. The straw was cut, ground in a knife mill and sieved. The portion used was the passing fraction of a Tyler 28 sieve, retained in Tyler 60. This portion was dried at 60 °C for 12 h and stored at room temperature until use.

Chemical characterization of rice straw

Rice straw was characterized by its proximal composition, using AOAC methods and determining contents of cellulose and lignin 12, fibers 13 and hemicellulose.14

Determination of enzymatic activity

The enzyme used was Cellic CTec2 (Novozymes). Enzymatic activity was determined using the method of Adney et al. 15, which was adapted in laboratory using filter paper Whatman No. 1. Reducing sugar content (RSC) was determined by the 3,5-DNS method.16

Pretreatment

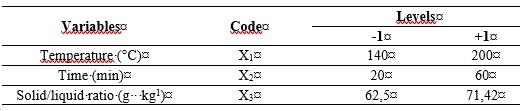

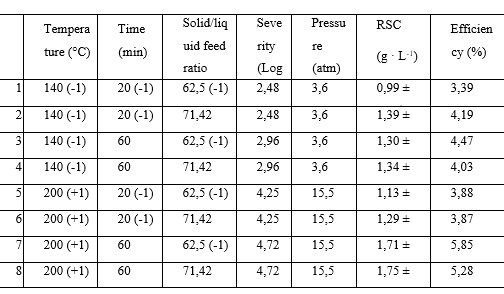

Pretreatment was performed in a teflon vessel with a teflon cap, with total volume of 75 mL. The vessel with cap was placed inside a cylindric recipient made of stainless steel and hermetically sealed, built for this purpose. This set, referred to as teflon bomb, resists to conditions of high pressure and temperature (up to 250 °C). The conditions for the pretreatment are presented in table 1.

The pretreatment was performed in batch, using a complete 2³ factorial design. This experimental design involved the variables of temperature (140 and 200 °C), time (20 and 60 min) and straw/water ratio (62,5 and 71,42 g of straw per kg of water). The set was stored in an incubator with forced air circulation and controlled temperature. The heating rate obtained was 5 °C.min-1, whereas the pressures were 3,6 and 15,5 atm, respectively. Pressures were estimated using a saturated steam table.17

After each batch, the teflon bomb was cooled using running water, until it reached room temperature. The pretreated material was removed from the bomb, separating solid and liquid fractions by filtering. After wash with distilled water, the solid residue was dried in incubator at 105 °C for 12 h, conditioned in Falcon tubes and stored under refrigeration, until its use in enzymatic hydrolysis.

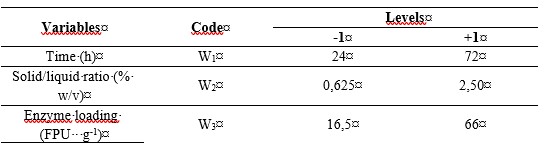

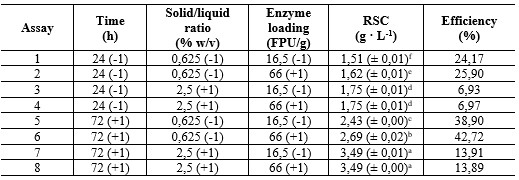

Enzymatic hydrolysis

The enzymatic hydrolysis of rice straw was performed under the conditions defined in the experimental design (table 2). The hydrolysis of non-pretreated straw was performed with ground straw (mesh 60), dried at 105 °C, in a medium of 50 mM sodium citrate buffer solution (pH 5,0).

The enzymatic hydrolysis of pretreated rice straw was performed using the resultant material from pretreatment, following the factorial design (table 2). In both cases, the response variable was the reducing sugar content, determined by 3,5-DNS.16

Determination of enzymatic inhibitors

The determination of degradation products of sugars was performed using a Shimadzu high performance liquid chromatograph (HPLC), equipped with an SPD-20A UV detector, a 25 cm CLC-ODS column, a G-ODS precolumn and a SIL-20A injector. Determinations were performed at constant temperature of 40 °C for column and detector. Elution was performed in isocratic mode, being the mobile phase composed of 90 % ultrapure water and 10 % acetonitrile, with outflow of 1 mL/min. For the detection of acid components, the wavelength used was 220 nm; for HMF and furfural, 284 nm. The total time elapsed was 13 min.

Determination of total phenolic compounds

The total phenolic compounds content was determined using the Folin-Ciocalteu method 18, adapted in laboratory. 50 µL of the sample were added to a mixture of 950 µL of Milli-Q water and 1500 µL of Folin-Ciocalteu reagent. After 3 min of repose, 2 000 µL of sodium carbonate (10 % w/v) were added. The samples were kept in the dark for 4 h at room temperature, and absorbance was read at 765 nm. Gallic acid solution was used as standard.

Scanning electron microscopy (SEM) analysis

SEM images were generated using a Jeol JSM-6610LV scanning electron microscope with an EDS microprobe, in the Southern Center of Electron Microscopy (Centro de Microscopia Eletrônica da Zona Sul — CEME-SUL, FURG, Rio Grande, Brazil). The images were obtained using samples dried at 105 °C for 8 h and covered with gold, using a Denton Vacuum Desk with 19 mA for 120 s.

Experimental designs

The pretreatment was performed using a 2³ factorial design (table 1). The response variable was the reducing sugar content (RSC).

The solid/liquid ratio (straw/water) used is close to the range proposed by Santos et al. 19, Yu et al. 6 and Díaz et al.20 — between 6 and 10 % in weight.

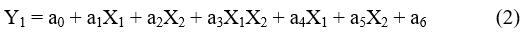

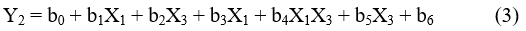

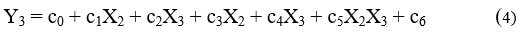

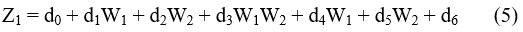

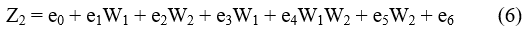

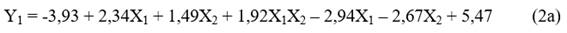

First degree equations were designed in order to describe the correlation between independent variables and the response variable (eq. 2-7).

The enzymatic hydrolysis was performed using another 2³ factorial design (table 2).

The statistical package used to analyze the fit of empirical data to a 2k model was 2(k-p) standard design (Box, Hunter & Hunter) in software Statistica® 7.0. The package was chosen because it gives a short, simple and accurate mathematic model for the statistical fitting of empirical data.

Results and discussion

Rice straw composition

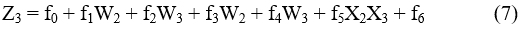

The chemical composition of rice straw (cultivar BRS AG) is shown in table 3.

The cellulose, hemicellulose and lignin contents found in BRS AG are similar to values reported by other authors 21,22 who used other varieties of rice straw with low lignin content. The carbohydrate content above 70 % makes the BRS AG straw an important substrate for the obtention of fermentable sugars. The ash content below 15 % indicates good potential for the biomass to be digested. Also, the moisture content below 10 % can predict low energy demands to dry the material to be processed.

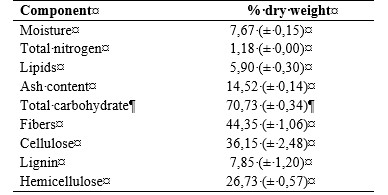

Reducing sugar content (RSC) — sugars produced by enzymatic hydrolysis of non-pretreated rice straw

The enzymatic hydrolysis in non-pretreated raw material promoted the solubilization of reducing sugars, which occurred proportionally to enzymatic activity. This is seen in figure 2, where RSC, expressed in mg of equivalent glucose, is directly proportional to enzymatic activity. It is independent from the enzyme: substrate ratio (FPU · g-1), remaining practically constant between 50 and 100 min of treatment.

The enzymatic hydrolysis of non-pretreated lignocellulosic feedstock releases RS in minimal amounts, rapidly stabilizing due to the inaccessibility of the enzyme to β-glycosidic bonds in cellulose. The efficiency observed was 3,40 % for RS. In a similar study, Yu et al. 6 observed increase in efficiency when performing pretreatment before enzymatic hydrolysis. To increase efficiency in terms of RS, experimental designs were proposed so as to analyze the behavior of the system when submitted to previous hydrothermal treatment and subsequent enzymatic hydrolysis.

RSC — sugars produced by hydrothermal treatment

As observed in table 4, the pretreatment of samples promotes higher release of RS from rice straw, even before enzymatic hydrolysis. This can also be observed in figure 3. The proportion of 62,50 g of straw per kg of water, under treatment at 200 ºC for 60 min, resulted in higher production of RS, as can be seen in table 4, assay 7. Under these conditions, cellulose fibrils may have been more swollen, which allows higher release of RS. On the other hand, lower temperature and shorter pretreatment time do not favor the rupture of fibers in cellulosic material. In these conditions, the pressure exerted over the system was 15,5 atm.

When lignocellulosic feedstock is submitted to temperatures over 140 °C and pressure above 15 atm, it causes defibrillation.10 In rice straw, cellulose can be found in its crystalline phase, highly ordered and compacted. Therefore, the use of high pressure reinforces the process of separation of polymers and the release of glucose. The release of RS increases as higher temperature and pressure are used in the pretreatment. Saturated steam was obtained in the process using teflon bomb.17

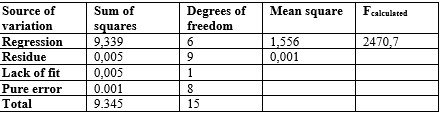

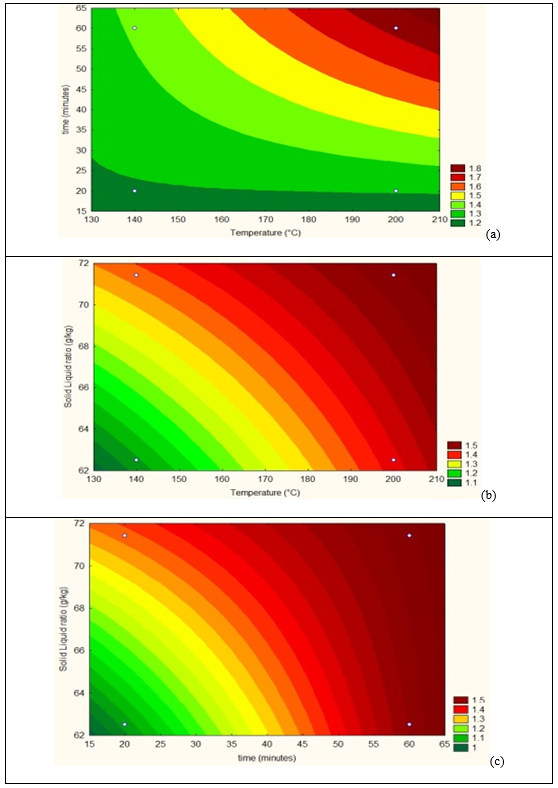

From the results in table 4, it can be inferred that temperature, time and pressure are the predominant variables in the pretreatment. This effect can be corroborated by the contour lines in figure 3 (a-c).

The contour lines demonstrate that the RSC increases proportionally to temperature and time. Díaz et al. 20 showed that higher RS efficiency also presents the same tendency in pretreatment.

The use of pretreatment, especially hydrothermal, is crucial to break the recalcitrance of the lignocellulosic structure for enzymatic hydrolysis. This recalcitrance occurs due to the sealing of lignin, the enclosure of hemicellulose over cellulose and the crystallinity of cellulose itself.6

Fig. 3 RSC contour lines in pretreated samples. (a) Effect of time and temperature; (b) effect of solid/liquid ratio and temperature; (c) effect of solid/liquid ratio and time

The comparison of RSC averages, using Tukey test at 5 %, is presented in table 4. It is possible to observe more uniformity among averages, and the highest production of RS is observed in assays 7 and 8. Both assays were conducted at 200 °C for 60 min.

According to other authors 5,6,23, temperatures below 140 °C can result in low sugar efficiency, whereas heat above 200 °C can cause sugar degradation, and consequently, lower concentration of hydrolyzed material. Yu et al. 6 also observed increase in glucose efficiency related to longer pretreatment times, in consonance with results observed in this study.

Favorable effects induced by hydrothermal treatment include: (i) expansion of surface area, caused by delignification, degradation of hemicellulose and increase in pore size, and (ii) changes in microstructure, including reduction in crystallinity and biomass defibrillation. Due to these factors, hydrothermal pretreatments can also be deemed appropriate for lignocellulosic raw material, in order to enhance its use as substrate for the enzymatic hydrolysis of cellulose.5

Inhibitors and phenolic compounds

The presence of acetic, formic and levulinic acids was not detected. However, the following enzymatic inhibitors were detected: furfural (0,580 ± 0,090 mg · L-1) and 5-(hydroxymethyl) furfural (5-HMF) (1,322 ± 0,522 mg · L-1). The content of furfural that can inhibit enzymatic action is 1 g · L-1, according to 24, whereas the content of 5-HMF that could inhibit reaction medium is 1,5 g · L-1, according.25 Therefore, the contents of furfural and 5-HMF observed in this study did not pose an obstacle to the action of enzymes and yeasts.

The phenolic compounds content was estimated using the gallic acid analytical curve, and the total phenolic compounds detected in the soluble fraction were 0,402 g · L-1. Santos et al. 26 reported that a phenolic compounds content above 6 g · L-1 affects the enzymatic process. In view of this, the results found demonstrated that hydrothermal pretreatment does not produce a concentration of phenolic compounds that can inhibit enzymes or fermentation.

Solubilized reducing sugars (RS) in enzymatic hydrolysis after hydrothermal pretreatment

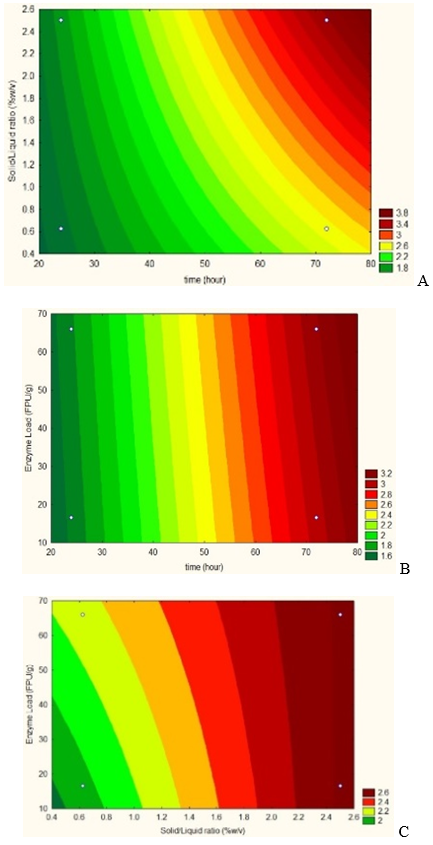

Figure 4A-C show the content of solubilized RS of solid fractions separated in hydrothermal pretreatment (200 °C, 60 min and straw/water ratio of 71,42 g · kg-1).

As can be observed, the content of solubilized RS increased proportionally to reaction time and solid/liquid ratio (figure 4A). As observed by Kim et al. 27, a substrate with high initial concentration of solids results in higher concentration of sugars and higher production of ethanol.

Fig. 4 RSC contour lines in different conditions of enzymatic hydrolysis. A: RS as a function of reaction time and solid/liquid ratio; B: RS as a function of reaction time and enzyme loading; C: RS as a function of solid/liquid ratio and enzyme loading

Figure 4B shows that RSC increases when reaction time is longer. On the other hand, enzyme loading has practically no influence on RS production. Kim et al. 27 observes that glucose efficiency was 40 % for cellulase loadings of 30 FPU · g-1, while the maximum efficiency was 47 % with the loading of 40 FPU · g-1. Therefore, this limitation in efficiency was observed with the increase in enzyme loading.

The correspondence between solid/liquid ratio and RSC can be limited by conditions of agitation of the reagent mass. This can hinder the contact between the solid and the enzymatic solution, in case the solids are in relatively high amount. However, in the concentrations of experiments, the increase in solid/liquid ratio showed to be directly related to the increase in RS concentrations.

Figure 4 C shows the combined effect of solid/liquid ratio and enzyme loading. The increase in mass of solid in the system influences the increase in RS produced. On the other hand, the increase in enzyme loading shows an almost negligible influence, in terms of increase in RS production. Therefore (figure 4C) demonstrates that the influence of enzyme loading on the increase in RS production is minimal.

Table 5 compares RSC averages using Tukey test at 5 %, evincing the variety among averages. A higher RS concentration is observed in assays 7 and 8, both conducted in 72 h of processing and solid/liquid ratio of 2,5 % w/v. Therefore, assay 7, with enzyme loading of 16,5 FPU · g-1, presents a more advantageous condition, requiring less enzymes to produce the same 3,49 g · L-1 of RS. In terms of efficiency, assay 6 presented the highest glucose efficiency: 42,72 %. A common factor among assays 6 (highest efficiency), 7 and 8 (highest concentrations) was the longer hydrolysis time (72 h).

Another aspect to be observed is the influence of hydrothermal treatment on enzymatic hydrolysis, causing increase in efficiency from 3,4 % to 42,7 %. Other authors that used similar processes observed this type of behavior, with expressive increase in glucose efficiency.6,27

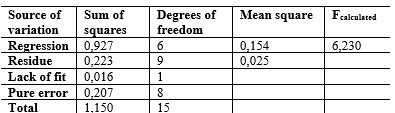

Mathematical modeling of factors and responses

Increase in RS production was observed using hydrothermal treatment. Therefore, two experimental designs were proposed in order to explore the best conditions of: (i) hydrothermal treatment, so as to facilitate the access of enzymes to cellulose in rice straw, and (ii) enzymatic hydrolysis, so as to obtain the best conditions for RS production. Release of RS was observed in two moments: (i) during hydrothermal treatment (Y1) and (ii) during enzymatic hydrolysis (Z1).

Contour lines for hydrothermal treatment were obtained (figure 3A-C). The equationing shows the mathematical behavior of RS extraction as a function of the factors analyzed. ANOVA was used for statistical analysis of significance for the model obtained (table 6).

Among the equations obtained, the ones that presented terms referring to non-significant variables (p > 0,05) were eliminated. Therefore, only equation (2) validated the experimental data:

Where:

Y1: RS obtained by hydrothermal treatment

X1: temperature in °C

X2: time in minutes

Equation (2a) demonstrated correlation of R² = 81 % and good adherence of the model to experimental data.

Contour lines for enzymatic hydrolysis were obtained (figure 4A-C). The equationing shows the mathematical behavior of RS extraction as a function of the factors analyzed. ANOVA was used for statistical analysis of significance for the model obtained (table 7).

Among the equations obtained, the ones that presented terms referring to non-significant variables (p > 0,05) were eliminated. Therefore, only equation (5) validated the experimental data:

Where Z1 is the RS obtained by enzymatic hydrolysis, W1 is the time in hours and W2 is the solid/liquid ratio (% w/v).

Equation (5a) demonstrated correlation of R² = 99 % and good adherence of the model to experimental data. It was observed that Fcalculated was three times higher than Ftabulated, which demonstrates that the model is significant and predictive, according to the ANOVA.

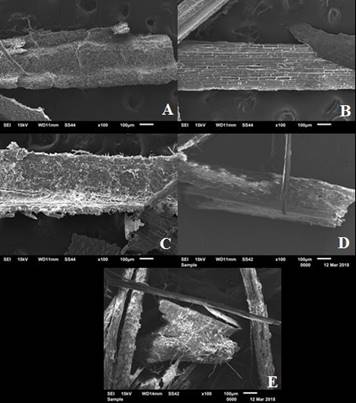

Scanning Electron Microscopy (SEM)

The main purpose of hydrothermal pretreatment is to facilitate the access of enzymes to the cellulose inside rice straw.

The effect of hydrothermal pretreatment can be observed in the microphotographs (figure 5B and 5C). They show alterations in cellulose fibers, which facilitate the access of water and enzymes. Hence, it is expected that the more substantial structural alteration is, the higher the degree of enzymatic hydrolysis will be.

Fig. 5 Images of rice straw generated by a scanning electron microscope (SEM), before and after hydrothermal pretreatment

donde:

(A) BRS AG rice straw before undergoing any pretreatment; (B) BRS AG rice straw pretreated at 140 °C, 20 min and 62,5 g of straw/kg of water; (C) BRS AG rice straw pretreated at 200 °C, 60 min and 71,42 g of straw/kg of water; (D) BRS AG rice straw after enzymatic hydrolysis (24 h, 0,625 % w/w of solid, 66 FPU/g); (E) BRS AG rice straw after enzymatic hydrolysis (72 h, 2,5 % w/w of solid, 66 FPU/g).

Conclusion

The enzymatic hydrolysis of non-pretreated rice straw (cultivar BRS AG) produces 3,40 % of sugars (expressed as equivalent glucose). The pretreatment of rice straw in teflon bomb at 15,5 atm promoted the solubilization of 5,85 % equivalent glucose. The enzymatic hydrolysis of pretreated rice straw provided 42,72 % of reducing sugars (expressed as equivalent glucose). The contents of enzyme inhibitors were 0,580 mg · L-1 for furfural and 1,322 mg · L-1 for 5-HMF. The microscopy exam of structures of cellulose and hemicellulose fibers demonstrate that rice straw is substantially altered in both treatments. Therefore, the results suggest that hydrothermal pretreatment with teflon bomb can obtain reducing sugars.