INTRODUCCIÓN

One of the more important steps in the production of Cuban rums is the aging process in oak barrel. Traditionally, Cuba has to import barrels because the only oak specie growing in the country, Quercus oleoides, is poor in forests and not useful for cooperage. It is well known that the major geographic areas supplying oak barrels are North America and Europe, especially France and in less extension Spain, Portugal, Russia, Bulgaria and Hungary, with mainly three species involved: Quercus alba at the first area and Quercus robur and Quercus petraea in the second, although Spanish ones (Quercus pyrenaica and Quercus faginea) have been tested in the last years, and some report for chesnut has been made (Caldeira et al., 2002, 2006; Fernández de Simón et al., 2003; Díaz-Moroto et al., 2004).

These oak woods used in cooperage, composed mainly by cellulose, hemicelluloses and lignin, have a wide range of a low molecular weight compounds such as fatty acids, esters of fatty acids, phenols, lactones, terpenes, furanic derivatives and carotenoids, furanic derivatives and carotenoids, which can be extracted by wine and spirits during the aging process.That it can be extracted by wine and spirits during the aging process (Pérez-Coello et al., 1999; Nonier et al., 2004). The chemical composition of oak wood has high variability among trees, species and geographical locations and is influenced by silvicultural practices, the age of the wood, besides other cooperage factors such as type and time of dryness of the wood, split or saw to cut staves, the heat treatment to bend staves and toasting or charring the inner surfaces of barrels. These variations can produce differentiations in chemical composition and sensory characteristics of the wine and spirits aging in oak barrels (Cadahía et al., 2001; Dussot et al., 2002; Fernández de Simón et al., 2003).

At present, in Cuba there are lots of barrels with an unknown origin, American ones which are majority and others from specific countries. Taking into account these facts, the purpose of this paper was to evaluate the volatile compounds among three lots of known origin (American and former Yugoslavia and Soviet Union) and three lots of unknown origin in order to establish differences or similarities among them.

MATERIALS AND METHODS

Materials

Six lots of barrels with different time of use and origin were chosen: Lot 1 former Yugoslavia (Yu), lot 2 American (Am), lot 3 former Soviet Union (SU), and lots 4, 5 and 6 unknown (Uk 1, Uk 2 and Uk 3). A total of 30 barrels per lot were chosen in a random way.

Sample preparation

For each barrel, one stave was taken out and cut in four pieces, all sides planed down in order to eliminate dirties and, in the case of the inner surface in contact with distillates, 10 mm deep was removed. Then, each four sections per stave were ground and carefully sieved to get oak chips (20-40 mesh) and well mixed. With the 30 oak chips samples per lot of barrels, three composite samples per lot were prepared mixing equals portions by weights of 10 stave oak chips.

Preparation of oak chip macerate

Oak chips (20 g) were placed in a tight glass container and 750 mL of hydroalcoholic solution 55% v/v ethanol was added. The time of maceration was 30 days with daily stirring. At the end of maceration time, oak macerate was filtered and the oak chips were washed with the hydroalcoholic solution and, the oak extract made to 1 L with the same hydroalcoholic solution used to wash the chips.

Isolation of volatile compounds

Oak macerate (25 mL) was diluted with distillate water to 100 mL in a volumetric flask. Fifty mL of diluted macerate were placed in a 100 mL Erlenmeyer flask with cap containing 15 g of ammonium sulfate and 50 µL of γ-nonalactone (200 mg/L) in ethanol 95 % v/v) was added as internal standard. The mixture was stirred until complete solubilization. Three extractions were then carried out using 10, 5, and 3 mL of dichloromethane (Sigma-Aldrich, 99.9 %) in a separatory funnel and centrifuged at 700g for 3 min. The organic fractions were combined and dried over night with anhydrous sodium sulfate, and then concentrated to 100 µL under a nitrogen stream. Extractions were replicated two times.

GC-MS analysis

Analyses were performed using a HP 6890 gas chromatograph (Hewlett-Packard Co., Palo Alto, CA) equipped with a mass selective detector model HP 5973. Samples were injected in a split mode injector at 250 ºC (split ratio of 1:70) on SPB-5 (Supelco, 30 m x 0.25 mm x 0.25 µm). The column temperature program was 60 ºC for 2 min and then at 4 ºC/min until 250 ºC, isothermal for 30 min. Helium as carrier gas at 1 mL/min. The detection by the mass spectrometer was performed in the EI mode (70 eV ionization energy). The acquisition was performed in scanning mode (mass range m/z 35-400 u). Identification of the constituents was based on comparison of the retention times with those of authentic samples, comparing their linear retention indices relative and on computer matching against commercial libraries (NIST 02, Wiley 275, Palisade 600 and ADAMS 2001) and FLAVORLIB homemade library mass spectra built up from pure substances. Some of the identifications were confirmed by the injection of the chemical standards into the GC-MS system. Linear retention indices of the compounds were calculated using an n-alkane series. Quantitative determinations were carried out according to the internal standard method without consideration of isolation yields and calibration factors for all compounds. All analyses were replicated two times.

Statistical analysis

Chemical data were analyzed using Statistica 7.0 software (StatSoft, Inc., Tulsa, OK) for mean and standard deviation, Principal Component Analysis (PCA) and Discriminant Analysis (DA). For PCA was used an n x p matrix where p = 96 variables (volatiles compounds concentration) and n = 18 samples analyzed. The graphic of each principal component was used as exploratory criterion for graphic differentiation of samples. For DA it was started from an n x p matrix where p = 4 (the fourth first principal components) an n = 18 analyzed samples, working with four groups and a Lambda Wilkis = 0.0013; F (8, 16) = 174.3 for p ( 0.01 and a tolerance value of 0.01 according to standard stepwise method (Montgomery, 2001).

RESULTS AND DISCUSSION

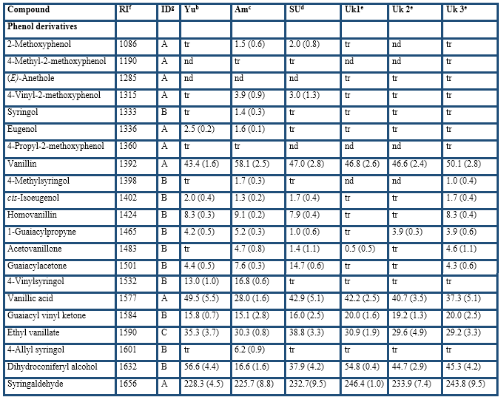

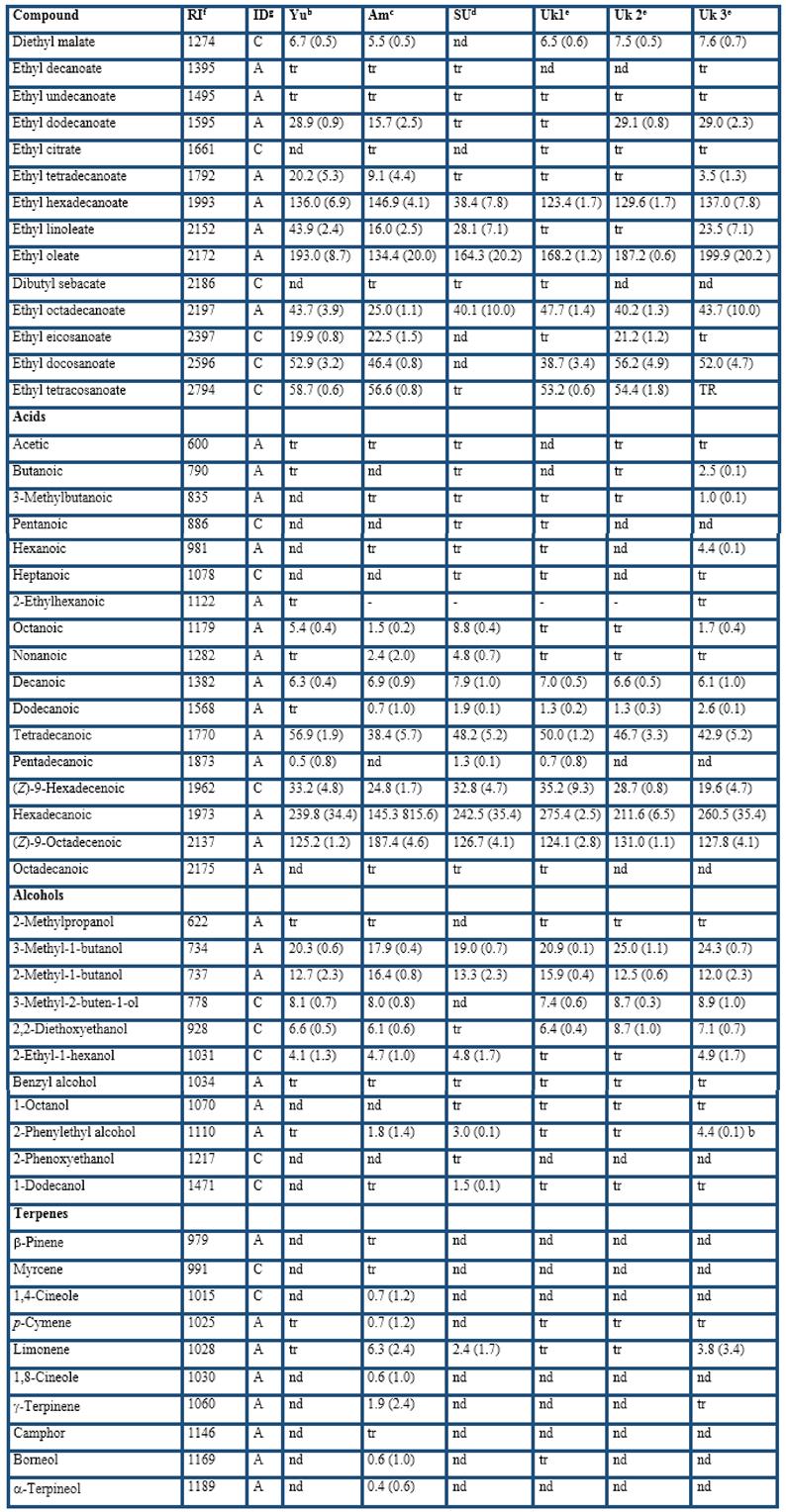

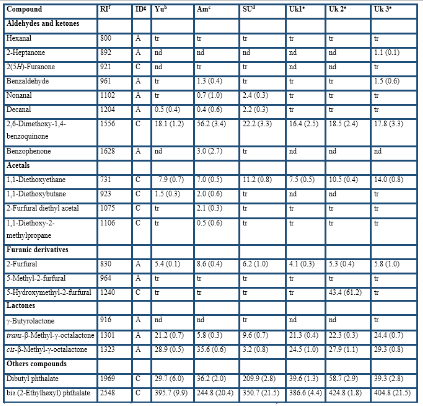

Table 1 shows the 126 volatile compounds found in the oak macerates, including phenol derivatives (40), esters (28), acids (17), alcohols (11), terpenes (10), aldehydes and ketones (8), acetals (4), furanic derivatives (3), lactones (3), and others with different functions (2). The major amounts of compounds were quantified in Am barrels (98), follow of Uk 3 (73), Yu (69), SU (66), Uk 1 (57) and Uk 2 (57) barrels. All lots of barrels presented more lignin derivatives than the rest of compounds type, what it is normal for seasoned and toasted oak wood (Vichi et al., 2007; Fernández de Simón et al., 2009). A major qualitative and, in some cases, quantitative profile of Am oak wood barrels in phenolics, esters, aldehydes and ketones, furanic derivatives, terpenes, and the major concentration of cis-β-methyl-γ-octalactone made this type of barrel different of the rest. On the contrary, SU oak wood barrels had the minor qualitative and quantitative profile in esters, alcohols and oak lactones, which made a difference from the rest of oak wood barrels. Yu, Uk 1, Uk 2 and Uk 3 barrels have a similar behavior, although Uk 3 has a greater qualitative and quantitative profile in this group.

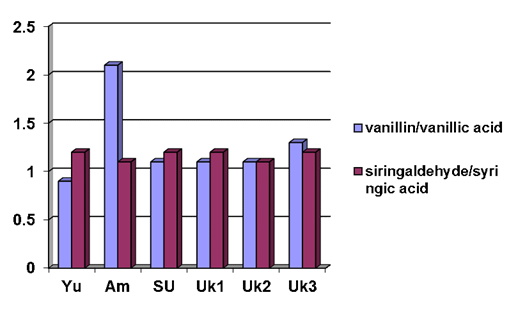

The Am barrels gave the major amounts of vanillin and coniferaldehyde and the minor concentration of syringaldehyde and sinapaldehyde, as show Fig. 1, where vanillin/vanillic acid and syringaldehyde/siringic acid ratios are shown. The major content of vanillin in Am barrels agreed with previous reports (Cadahía et al., 2001).

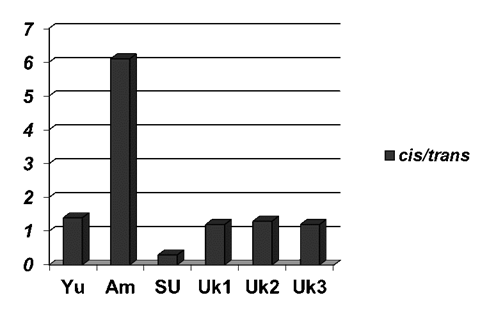

Very important compounds like trans-β-methyl-γ-octalactone and cis-β-methyl-γ-octalactone were in very similar concentrations in Yu, Uk 1, Uk 2, and Uk 3 barrels, having the major content of total lactones. The Am barrels showed the major concentration of cis isomer and the minor of trans isomer, whereas the SU barrels have the lower level of total lactones, which is agree with some report for Russian oak (Mosedale et al., 1999). Cis/trans ratio (Fig. 2) for Yu, Uk 1, Uk 2 and Uk 3 barrels are below 2.0 which agreed for European oak wood whereas Am barrels has a value of 6.1 which is typical for American oak wood. The values found for cis/trans ratio agreed with those found for some authors where this value was higher in American oak wood than in European ones (Pérez-Coello et al., 1999; Pérez-Prieto et al., 2002). SU barrels show a value of 0.3, and this value is closer to European oak wood than to American Q. alba. In general, it is considered that the American white oak (Q. alba) and Q. robur and Q. petraea from France, have the major concentrations of oak lactones versus the rest of European oaks, with a major concentration of cis isomer in American white oak (Pérez-Coello et al., 1999; Díaz-Moroto et al., 2004).

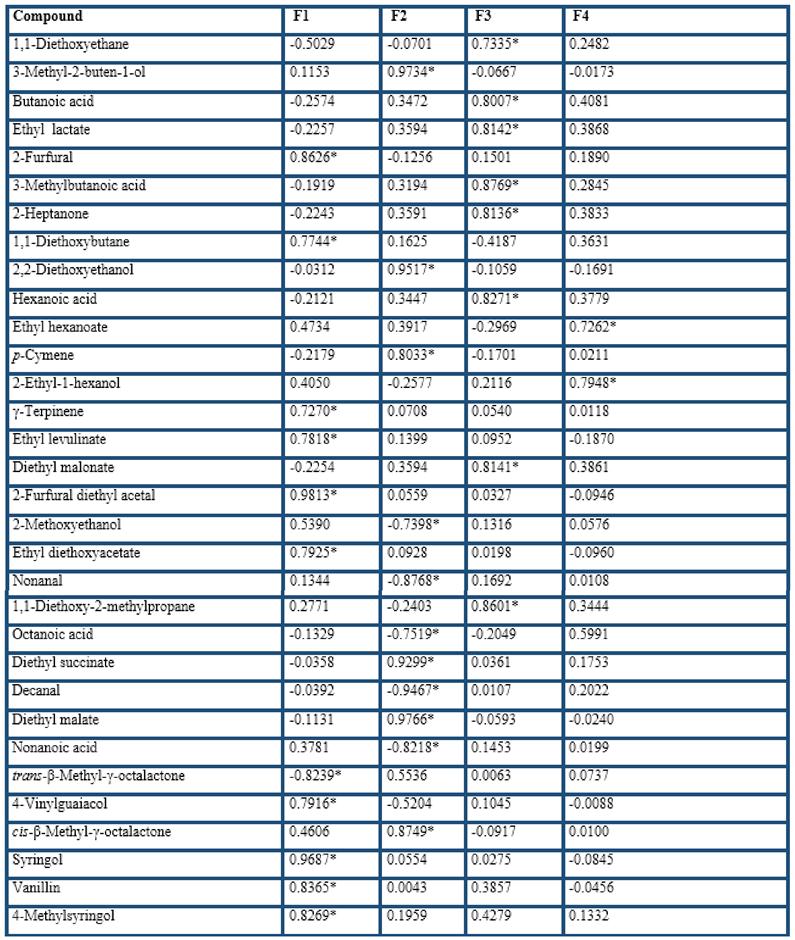

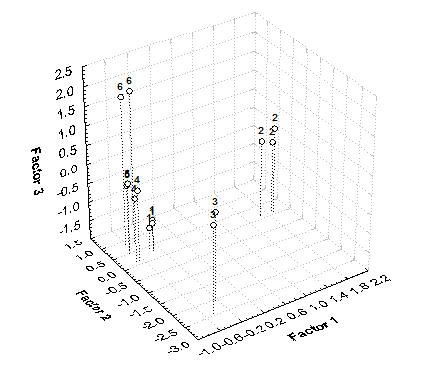

PCA analysis showed that four principal components with eigenvalues greater than 1 explained 82.8 % of variance (F1 34.4 %, F2 22.7 %, F3 14.8 %, and F4 10.9 %). The graphical representation of three first principal components showed four groups well defined with an appreciated statistical distance among the groups (Fig. 3). Group 1 was the more represented and it was formed by samples of Yu, Uk 1 and Uk 2 barrels; to the second group corresponded samples representing Am barrels; the third group was formed by samples of SU barrels and the fourth group consisted of the samples of Uk 3 barrels.

Table 2 show loading factors for each principal component. In F1, there were among compounds with statistical significance 2-furfural, γ-terpinene, trans-β-methyl-γ-octalactone and vanillin; in F2, p-cymene, o-guaiacol, decanal and cis-β-methyl-γ-octalactone, these with great importance because of their relevant in different sensory characteristics (Caldeira et al., 2002; Pérez-Prieto et al., 2002; Fernández de Simón et al., 2003, 2009). On the contrary, in F3 the compounds with statistical significance are irrelevant for the aging process and their sensory impact, except for 1,1-diethoxyethane, because this type of compound has aromatic strength (Puech et al., 2003). As all these compounds have different sensory properties, could be possible to expect certain differences in the aroma among oak macerates belongs to each group classified by PCA.

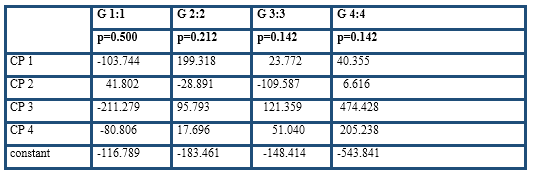

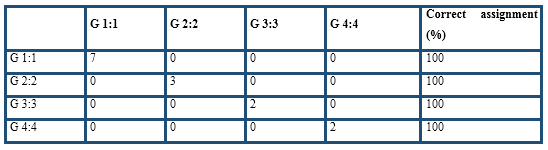

A discriminant analysis was done with the four first principal components. Table 3 shows the discriminant functions for the four groups where in the classify functions for group 1 (Yu, Uk 1 and Uk 2 barrels) and group 2 (Am barrels), the F1 was the more contributing, especially for the group 2, whereas in the classifying functions for the group 3 (SU barrels), the major contribution belongs to F2 and; for the group 4 (Uk 3 barrels), the main contribution was for the F3. The classification matrix (Table 4) shows how the classification functions predict the membership of the observations, where all samples were correctly classified (in the diagonal matrix). The cross validation employed, the know “U Method” (Leave-one out), where each observation is classified using the classification functions (or Fisher's lineal discriminant functions), derived from the rest of the observations gave a 100% of correct classifications, having a similar result showed in Table 4. As the cross validation is a better measure of the discriminating power of the classification functions, it may considerer that the estimated classifications functions can be used to predict correctly to which group belongs a new sample of the oak woods studied.

Table 1 (cont.)

a Mean (standard deviation); tr: ≤ 0,1 μg/g of wood; nd: none detected. bformer Yugoslavia barrels. cAmerican barrels. dformer Soviet Union barrels. eunknown origin barrels. fRetention index on HP-5MS. gID: the reliability of the identification proposal is indicated by the following: A, mass spectrum and retention index agreed with standards; B, mass spectrum and retention index agreed with literature data; C, mass spectrum agreed with mass spectral database.

Fig. 1 Vanillin/vanillin acid and syringaldehyde/syringic acid ratio in barrels. Yu: former Yugoslavian, Am: American, SU: former Soviet Union; Uk1, Uk2 and Uk3: Unknowns 1, 2 and 3.

Fig. 2 Cis/trans relationships for oak lactones isomers in barrels. Yu: former Yugoslavian, Am: American, SU: former Soviet Union; UK1, Uk2 and Uk3: unknowns 1, 2 and 3.

CONCLUSIONS

It was established that the three lots of barrels with known origin (American, former Yugoslavian and former Soviet Union) gave a different compounds profile according to its origin and belongs to different types of wood, as it was confirmed by PCA and DA. Two lots with unknown origin (Unknown 1 and 2) gave a compound profile like former Yugoslavian barrels and belongs to the same group defined by multivariate analysis and, for that reason, we assume that these barrels coming from Europe. The Unknown 3 barrels, although belongs to a different group in PCA to the rest, is closer to come from Europe than from other origin because their quantitative compound profile is closer to former Yugoslavian than American or former Soviet Union origin, mainly if we are bearing in mind the cis/trans ratio of β-methyl-γ-octalactone.