INTRODUCTION

The decision making in agricultural mechanization is complicated by the high number of factors to be taken into account when planning a technological process in agriculture, but also, if the means to face it are heterogeneous in terms of the machinery park and the edaphoclimatic conditions for the cultivation of sugarcane, the situation reaches a greater degree of complexity.

The use of computer media has proven to be a very effective and efficient tool in decision making, where multiple variables intervene. It provides remarkable results in the reduction of execution time and in absorbing sudden changes providing immediate solutions (Sotto et al., 2006; Martínez et al., 2014, 2014; De las Cuevas et al., 2015; Pereira et al., 2015; Álvarez et al., 2015).

To analyze the operation of the machinery specifically, the software ANAEXPLO, on Excel platform, was developed in the country, aimed at the analysis of the deficit-surplus of mechanized means in the service units of machinery (Sotto et al., 2006). The achievement of maximum veracity, as referred by the author, depends on that the technology proposed for each crop, the aggregations and the correspondent indicators obey to the reality of the production, the concrete conditions of exploitation in each unit and the particularities derived from the type of soil.

However, if in the development of an application for the same purposes, the obtaining of technological charts is included, with the conception from the initial stage of the work of the machinery grouped in platoons, it is possible to obtain integral recommendations at the same stage. That includes the agronomy of the crop, the analysis of machinery exploitation and the demand of supplies, which reduces the time, allows achieving greater precision in the results and minimizing errors.

On the other hand, the work of tillage for the plantation of sugarcane and cultural attention to the crop should be planned in such a sense that meet the requirements with opportunity, quality and environmental sustainability. For that, it is essential to identify the properties of the environment to be transformed and its edaphic limitations, climatic conditions and available equipment (Betancourt et al., 2015). In the productive practice of the country, this is not the case. The work is improperly planned, for example, a soil with problem of stoniness receives the same management as one that has little effective depth, or bad drainage.

It has brought unfavorable results in the plantation and development of sugarcane because a suitable plantation bed has not been established; likewise, soil degradation due to poor management is favored.

The rapid development of information technology, the need to improve soil tillage in Sugar Business Group (AZCUBA), the experience of Sugar Cane Research Institute (INICA) in implementing scientific-technical services, with computer tools for decision-making (Arcia et al., 2004) and the results of more than 40 years of research in tillage, may help improving the soil tillage planning for sugarcane production, by using an automated decision-making system.

The objective of this work is to show the main characteristics of the automated system LabraS developed for the decision making in the planning of soil tillage for sugarcane.

METHODS

Deforestation, leveling, soil preparation, planting, fertilization and post-harvest cultivation are the technological processes designed for planning through the automated system. The recommendations exclude everything related to the standards and dosage of the fertilizer as they corresponds to the Service for the Recommendation of Fertilizers and Amendments (SERFE) and the herbicides and their doses for belonging to the Integrated Weed Control Service (SERCIM).

The existing coders in AZCUBA Business Group were used. They were the identifier of Sugarcane Companies (EA), Base Business Units (UEB), Production Units (UPC) and the Blocks, which served to link with the Unique Database (BDU) and the rest of the scientific-technical services provided by INICA. A sugarcane block is the minimum management unit for issuing the recommendations.

Soil texture refers to the relative proportion of different groups of mineral particles in the soil (Cairo & Fundora, 2007)1. The coding used in the preparation algorithms of the plantation bed defined light, medium and heavy, according to the texture corresponding to the agro-productive groupings of soil for sugarcane established by INICA (Table 1).

TABLE 1 Agro-productive grouping of soils and their texture

| Agroproductive grouping | Texture |

|---|---|

|

Calcium Ferrallitized Ferritized Quartzites Ferrallitized Calcium Fersialitized |

Light Media |

|

Calcium Sialitized Non-Calcium Sialitized Vertisols Calcium Gyalzados Sialitized Ferralitized Gyalzados Alluvials |

Heavy |

Based on the limiting factors for mechanization proposed by Cairo & Fundora (2007) and Santana et al. (1999), effective depth, salinity, drainage, stoniness, slope and compaction were considered on the recommendation of technological indications. It was due to their high weight on technological changes in tillage and for being referred in the digital information of the map 1:25 000, used for evaluating soil physical aptitude by INICA. The characteristics of the information to be processed, the categories of the limiting factor that determine their presence or not in the conditions evaluated and the procedures to be applied were carried out according to the methodology proposed by Betancourt et al. (2011). It should be noted that the absence of any of these factors for this case gives rise to the soils without limitations for the mechanization of soil tillage.

The energy sources, the implements and the aggregates considered the inventory of tractors and implements of the Azucarero AZCUBA Group. Exploitation indices such as the performance per day (ha/day), fuel expense (L/ha) and cost (peso/ha) for work and types of maintenance per equipment brand were taken from the planning indicators established in AZCUBA.

The technological variants and their work in the alternatives per processes and the period between soil preparation tasks took into account the results of the soil tillage research of INICA and other institutions of the country (Gómez et al., 1997; Santana et al., 1999; Crespo et al., 2013; Gutiérrez et al., 2013 and Oliva et al., 2014).

The herbicides and the doses recommended in the preparation of the area for the soil preparation and the preservation for the plantation were carried out prior coordination with the Expert Group of the Integrated Weed Control Service (SERCIM) of INICA.

The updating or modification of the coders of the system were due to the agreements reached in the meetings of the expert group from AZCUBA and INICA.

A methodology was established to request the data of the tillage processes to the sugarcane producer based on four models that identify the existing situation of the areas to be worked and the means of tillage (conformation of the squads, inventory of the equipment and actual days)(Pérez, 2018). They correspond to the information demanded by the software algorithms to recommend technological charts and selection of aggregates.

The operation analysis of the machinery was carried out using the expressions proposed by González & Tzucurov (1986) and González (1993).

The application was developed in a Microsoft Visual Studio 2013 Ultimate environment, the database was supported on Microsoft SQL Server Express Edition 2008 and Microsoft Report Viewer 2012 was used for the reports.

Three users were established: the producer with limited access to the system's coders and the conformation of technological alternatives (AT), INICA, as service coordinator in the territories with permissions to the coders, except the AT and the Administrator (the technologist) with free access.

The validation of the automated system was carried out in the UEB Melanio Hernández that belongs to Sancti Spíritus Sugar Company, using the information of the 2017-2018 campaign.

RESULTS AND DISCUSSION

The software designed for the planning of the tillage processes was named "LabraS" and was created for the Windows platform. The installation was made with facilities to the user for having a package with the following content: LabraS-Setup.exe and Binaries. The execution of the LabraS-Setup.exe file is responsible for carrying out the entire process following a sequence of interactive instructions with the user. Table 2 presents the hardware requirements to perform the installation and successful execution of the application.

TABLE 2 Main hardware requirements for software installation

| Parameters | Minimum Values | Recommended Values |

|---|---|---|

| CPU | 1 GHz | Superior |

| Memory | 512 MB | 1 GB or higher |

| Disc space* | ||

| • With the local database | 2 GB | Unlimited |

| • With the database on another server | 1 GB | Unlimited |

| Monitor resolution | 800 X 600 | 1024 X 768 or higher |

| Windows Operating System | - | 32 bit or 64 bit |

The application for the producer does not require registration; however, to access the rest of the functionalities in the other users, the registration of the application is demanded, which is established for one year of work.

The software environment is shown in Figure 1. The main menus that make up the application are Processes, Recommendations, Reports, Encoders and Tools, located on the top or left side to facilitate interactivity with the user. The side menu is designed to be hiden, if the operator requires it.

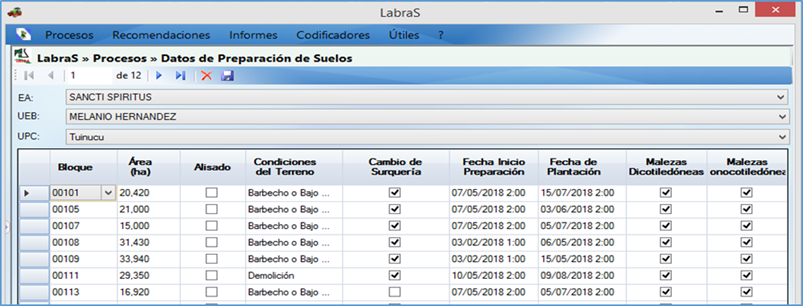

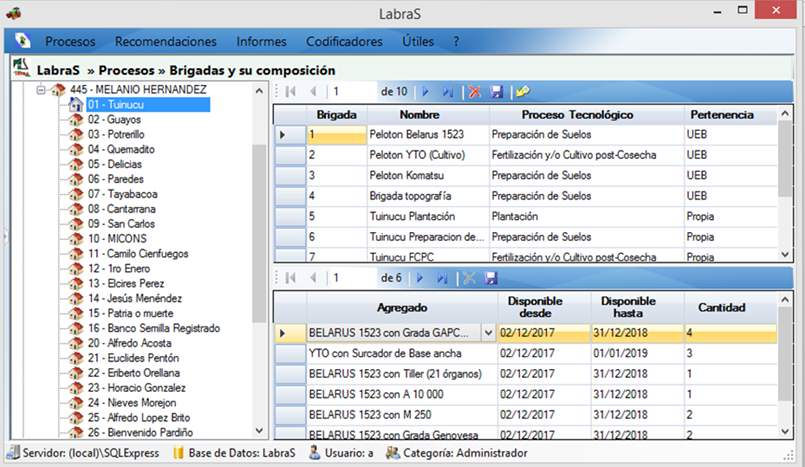

The Processes menu is designed to capture the input data requested from the producer, such as the information on the five tillage processes, the organization of the squads, the inventory of equipment, among others (Table 3). Figures 2 and 3 show, as an example, the windows for the capture of the data of ground preparation and the squads conformation, respectively

TABLE 3 Description of the Processes menu options

| Option | Description |

|---|---|

| Deforestation data | Area/Block/Type of vegetation/Date of execution |

| Basic leveling data | Area/Block/Terrain conditions/Execution date. |

| Soil preparation data | Area/Block/Soil limiting factor/Texture/Soil conditions/Smoothing requirements/Change of furrow/Predominant weeds/Date of execution/Planting time. |

| Planting data | Area/Block/Soil limiting factor/Irrigation/Workforce availability/Date of execution. |

| Fertilization and post-harvest tillage data | Area/Block/Soil limiting factor/Type of Harvest/Strain/Block population/Agricultural yield (t/ha)/Date of execution |

| Brigades or platoons | To conform the structure of the squads, aggregates and quantity, according to the technological process and their belonging. |

| Effective days | The total effective days per technological process per UEB |

| Inventory of energy sources (FE) and implements | FE and the implements that will participate in the tillage of soil according to their pertaining. |

| New machinery | Brands and models of energy sources and implements to recommend in the report of new machinery. |

In general, the capture of information is mostly done through a drop-down list or with the so-called Check Box, as it is also known for its terminology in English, to minimize time and errors when entering information.

It is important to highlight that the accuracy of the information provided by the producer in the data determines the quality of recommendations per block.

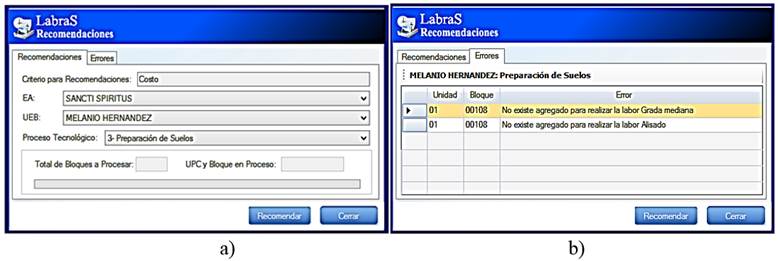

The Recommendations menu has a single option Issue Recommendations that when executed displays a dialog box with two tabs, Recommendations and Errors (Figure 4)

In the recommendations tab, the Sugar Company, the Business Unit and the Technological Process to which the recommendations will be issued are selected. While the information is processed, the total of blocks and the block in process are shown, which facilitates the identification of the block that shows some error in the captured data, if the recommendation for that cause is stopped. The second file presents the work that does not have a declared aggregate in the squads of the specified Unit and that prevents the completion of the technological card. This problem is solved by incorporating the aggregate in the brigade, which is located in the option Brigades or Platoons of the Processes menu.

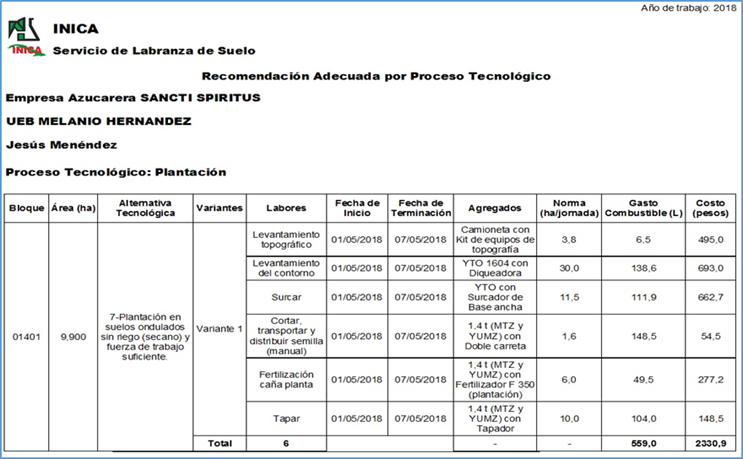

The Reports menu includes all the recommendations regarding technological charts, analysis of the exploitation of machinery, supplies (filters, lubricating oils, greases, tires, belts, etc.), demand for herbicides for soil preparation, proposal of new machinery, among others. Table 4 presents the reports of limiting factors for mechanization and technological charts.

TABLE 4 Reports of the limiting factors for mechanization and technology charts

| Report | General description |

|---|---|

| Map of the most limiting factor for tillage | The map is generated in the MAPINFO software from the most limiting factor selected by the software. |

| Summary of the most limiting factor for tillage | It shows the area and the percentage of limiting factors at UPC, UEB and EA level, as selected by the user. |

| General recommendation per technological process | It defines the possible variants per technological alternatives. It is designed for the consultation of the software operator. |

| Appropriate recommendation per technological process | It presents the technological chart per management unit according to the selected technological process. It is the one given to the producer in the recommendations manual. |

| Ideal recommendation per technological process | It identifies the ideal variant per technological alternative whether or not there are aggregates in the platoon. It is designed to consult the software operator. |

| Summary per block | It presents the technological charts of all the processes to be carried out for the minimum management unit (the block) in a single report. It is delivered at the request of the client. |

An example of a suitable recommendation for planting is shown in Figure 5.

The recommendation presents the tasks, the start and end dates, the aggregates and the main operating parameters for tasks depending on the area selected. It should be noticed that for the plantation the start dates coincide for all operations as it is the case in practice, but in processes such as soil preparation and post-harvest cultivation, this parameter includes the time between work established in the coder of the software and the one defined by the group of experts. In this way, it was demonstrated the possibility of obtaining in the same recommendation process, the technological chart for cultivation based on the technological process, which is based on the analysis of exploitation of the machinery and the demand for inputs.

Table 5 shows the reports related to the exploitation analysis and the demand for inputs.

TABLE 5 Reports linked to the exploitation and demand of inputs analyses

| Reports | General description |

|---|---|

| Squad Analysis | It determines the displacement and workload per months and year of the peloton. It is delivered at the request of the client. |

| Balance of energy sources and implements | It shows the balance in terms of deficit and excess of energy sources and implements separated from the UEB from the work specified in the technology charts. |

| General analysis | It presents four alternatives. 1. |

| New machinery | It presents the proposal of new equipment to be introduced. |

| Herbicide demand | It shows the demand for herbicides for conditioning and preservation of the area at UPC, UEB and EA levels. It is delivered in the manual of recommendations to the producer. |

| Demand for inputs | It presents the demand for inputs such as filters, tires, etc. per quarter for the tillage campaign. It is delivered in the manual of recommendations to the producer. |

| Inventory Equipment | It relates the inventory of energy sources and implements used in the software to issue recommendations. |

The description of the options on the Encoders menu is presented in Table 6. Those corresponding to Empresa, UEB and UPC coincide with those of the Unique Database of the Sugar Cane Research Institute and the rest are specific to the software.

TABLE 6 Description of the Encoders menu options

| Option | Description |

|---|---|

| Company | It shows the Sugar Companies. |

| UEB | It presents the UEB for the EAs. |

| Production units | It shows the UPCs according to the UEB and the selected EA. |

| Blocks | It relates the blocks of the selected UPC. |

| Technological alternatives | It allows the configuration of technological alternatives per technological processes. |

| Energy sources | It relates and configures the energetic sources of tillage |

| Implements | It relates and configures the implements. |

| Aggregates | It establishes tillage aggregates. |

| Work | It defines the tillage tasks and the aggregates with their exploitation rates to execute it, such as yield, fuel expense and cost. It allows establishing expert criteria for the selection of aggregates. |

| Inputs | It defines the general inputs used, such as oils, lubricants, filters, etc. and the general components of equipment such as the engine, speed box, differential, etc. |

| Term between labors | It defines the deadlines between labors per technological process. |

| Variants per technological alternatives | It defines the variants and their work per technological process. It allows to establish expert criteria for the selection |

| Herbicide for soil preparation | It specifies herbicides for conditioning and preservation of areas in soil preparation and doses |

| Inputs against equipment | It defines the capacity and period of changing of the inputs used for each component per equipment brand. |

| Select limiting factor | The limiting factors for machining are selected per minimum management unit (The block). |

| General data | The general encoders used by the software are shown, such as Technological processes, Limiting factors per process, Criteria for recommendation, among others. They are read only. |

The Tools menu is designed primarily to facilitate the exchange of information with the environment, to provide security and to protect the information (Table 7).

The UEB Melanio Hernandez has an extension of 12,791.8 ha destined to the cultivation of sugarcane, distributed in 15 Cane Production Units. The validation tests of the software were carried out in a total area of 6,430.76 ha. They were performed in 1,717.35 ha for soil preparation and planting processes and in 4,713.41 ha for fertilization and post-harvest cultivation.

The results obtained were satisfactory. The functionality of the algorithms in the selection of the limiting factors for the mechanization of the soil tillage, the adequate selection of the technological alternatives per the characteristics of the block, the variants and their tasks according to the selected alternative and the availability of the equipment was demonstrated. It was also proved, the feasibility of the calculations from the expressions and procedures used in the balance of machinery for both tractors and implements, the planning of work, the demand of supplies for maintenance and soil preparation herbicides and the proposal of new equipment (Pérez, 2018; Álvarez, 2018).

It is important to note that the LabraS software in version 2.0.0 is registered by the National Copyright Center (CNDA) with the Registry 2124-07-2017 (Betancourt et al., 2017).

Table 7 Description of the Tools menu options

| Option | Description |

|---|---|

| Configuration | It sets the operation index for the selection of aggregates and the year of work. It also defines the center that will issue the recommendations to be shown on the cover |

| Users | It defines the users that operate the software. |

| Change password | It facilitates the change of password depending on the user. |

| Import information | It provides the import of the system encoders, the single database and producer encoders. |

| Export information | It facilitates the export of system encoders and producer coders. |

| Import map of the limiting factor | It allows the import of the map generated in MAPINFO with the representation at the UEB level of the limiting factors |

| Save database | It facilitates the realization of the system's security copy. |

| DatabaseUtilities | It allows access to delete data, restore a backup or delete the database by running complementary software. |

| Register LabraS | It facilitates the registration of the application to move from roll of producer to INICA or administrator. |

| Finish | It closes the application. |

CONCLUSIONS

LabraS software for tillage planning was designed on a Windows platform, with easy installation and operation; a structure with five menus (Tools, Encoders, Reports, Recommendations and Processes) and three user roles (producer, INICA and the administrator).

The main reports include distribution of soil limiting factors for tillage, technology charts for technological processes, analysis of machinery exploitation and demand for inputs.

Validation of LabraS software in UEB Melanio Hernández provided satisfactory results in the testing of algorithms, procedures and calculation expressions.

texto em

texto em