Introduction

Milk and dairy products are nutritious foods due to the contents of proteins, minerals, vitamins, and fats they have (1). Every year their productions increase in the world. Cheeses are one of the most important dairy products. Around 20 million tons were produced in the year 2016 (2). In several geographic regions such as Latin America and the Caribbean, Asia and others, the artisan fresh cheeses are the preferred food by the population due to factors like tradition, low prices and the relevant nutrient sources.

Artisan fresh cheeses are those made up in the own dairy farms (3) under rustic conditions. The elaboration of these cheeses constitutes an old tradition in the countries of Latin America and they are in the preference of the populations of this region. These manufactures offer sustenance to many families and have an appreciable production volume (4).

In industrialized countries, outbreaks of foodborne diseases associated with milk and dairy products are between 2 % and 6 % (5,6). In developing countries, values ranging from 1 % to 10 % of total outbreaks are reported (7). In Cuba, official reports are 5 %, although it is recognized that it must be higher, if we consider that not all consumers who get sick go to health services (National Direction of Environmental Health, 2016). About 70 % of foodborne disease outbreaks due to the consumption of cheese are due to cheeses made up with unpasteurized milk (8). Between 50 % and 60 % of outbreaks in the United States and Europe, where dairy products have been implicated, the main cause has been the consumption of unpasteurized products (9).

About 70 % of foodborne disease outbreaks by eating cheese are due to cheeses made up with unpasteurized milk (8). Between 50-60 % of outbreaks in the United States and Europe, where dairy products have been implicated, the main cause has been the consumption of unpasteurized products (9).

Staphylococcus aureus (S. aureus) is considered one of the four pathogenic bacteria (Salmonella spp., Listeria monocytogenes and Escherichia coli STEC) which constitute a risk for the safety of cheese production (10,11). Foodborne diseases are widely related to S. aureus which is frequently detected in milk and dairy products (12). Specifically in cheese production, Arcuri et al. (2010) showed that the source of S. aureus contamination could be multifactorial, such as raw milk, processing environment, and handlers (13).

In Cuba, S. aureus is the most identified pathogen in foodborne disease outbreaks according to Ministry of Public Health (2016) (14). Different studies report data ranging from 3-6.8 log CFU/g in artisan fresh cheeses contaminated with S. aureus (15,16,17,18,19). However, there is not a clear perception of the risk by Cuban consumers and, therefore, the possibility of the presence of microbiological hazards in them. Moreover, there is not a standard of quality specifications for this type of fresh cheeses elaborate in an artisan way. These elements justify the objective of this study regarding the description of the food safety problem associated with the presence of Staphylococcus aureus in the production chain of artisan fresh cheese in Cuba.

Artisan fresh cheese in Cuba

Description of artisan fresh cheese

Cheese is described by Codex Alimentarius (CODEX-STAN-283-4, 2013) as being the “ripened or unripened, soft or semi-hard, hard and extra hard product”, which may be coated; and in which the whey protein/casein ratio does not exceed that of milk obtained by:

Coagulating wholly or partly the milk protein, skimmed milk or products, partly skimmed milk, cream, whey cream or buttermilk, through the action of rennet or other suitable coagulating agents, and by partially draining the whey resulting from such coagulation.

Processing techniques involving the coagulation of the protein of milk and/or products obtained from milk, which gives a product with physical, chemical and organoleptic characteristics similar to the product defined. Include unripened cheeses (fresh cheeses) which are ready for consumption shortly after manufacture (CODEX STAN-221-2, 2013).

Artisan fresh cheese is produced by the coagulation of the native microflora in raw milk and the artisan coagulate agent from pigs´ stomach. The coagulum is cut (forming curds), resulting in separating the whey, which is drained from the curds. The curd is salted before being pressed into the wooden molds. (Figure 1).

Figure 1 Flow chart of artisan fresh cheese production in Cuba./ Diagrama de flujo de la producción artesanal de queso fresco en Cuba.

The commercialization of these cheeses takes place informally, practically out of the control of the Public Health authorities (20). Different studies have reported problems in the sanitary conditions of these products (15,16,17,18,19,21).

Cheese production

In Cuba, cheese production is divided into two ways: industrial and artisan. In 2016, the industrial production was 20700 tons and the artisan one was 3751 tons (22). Artisan fresh cheeses are produced by the farm cooperative sector as raw material to the dairy industry for obtaining processed cheese.

Composition results in 95 samples of artisan fresh cheeses in Cuba are shown in Table 1. These cheeses are classified as: semi-fat since the fat content in the dry extract was higher than 25 % and lower than 45 %; soft because of moisture percentage; and without fat was higher than 67 %. These cheeses are not subjected to any ripening process, so they are considered fresh according to the Codex Standard 283-4: 2013.

Table 1 Composition of artisan fresh cheeses in Cuba./ Composición de quesos frescos artesanales en Cuba.

| Fat (g %) | Protein (g %) | TS (g %) | Moisture (g %) | Salt (g %) | pH | wa | |

|---|---|---|---|---|---|---|---|

| Mean ± SD | 26.92±4.6 | 20.96±3.8 | 52.93±5.7 | 76.65±5.7 | 0.77±0.6 | 5.25±0.1 | 0.96±0.2 |

| Minimum | 20.27 | 13.46 | 37.93 | 67.93 | 0.00 | 5.00 | 0.94 |

| Maximum | 36.03 | 37.85 | 65.00 | 92.32 | 2.96 | 5.50 | 0.98 |

Legend: TS: total solid, wa: water activity

Staphylococcus aureus

Description and growth characteristics

Staphylococcus aureus belongs to family Micrococcaceae, characterized as facultative aero-anaerobic, catalase-positive, non-spore-forming, gram-positive, coagulase-positive, non-motile coccus (occurring singly or in irregular grape-like clusters) (23). The physic-chemical parameters that contribute to S. aureus growth and enterotoxins production is shown in Table 2.

Table 2 Characteristic of Staphylococcus aureus growth and enterotoxins production./ Característica del crecimiento de Staphylococcus aureus y la producción de enterotoxinas.

| Optimal growth | Growth limits | Optimal SE production | SE production limits | |

|---|---|---|---|---|

| Temperature (°C) | 35-41 | 7-48 | 34-40 | 10-46 |

| pH | 6.7-7.5 | 4.5-9.8 | 7.5 | 4.6-9.6 |

| wa | 0.99 | ≥0.83 | 0.99 | ≥0.85 |

| NaCl ( %) | 0-4 | 0-20 | 0 | 0-10 |

| Redox Potential | >+200 mV | ≥200-> +200 mV | >+200 mV | ≥100-> +200 mV |

| Atmosphere | aerobic | anaerobic-aerobic | aerobic | anaerobic-aerobic |

Legend: wa: water activity

From (FSANZ, 2009) (9)

Enterotoxin Production

Staphylococcal intoxication results from the ingestion of staphylococcal enterotoxins (SEs) produced during the growth of S. aureus in food (in amounts >105 UFC/g). The SEs are potent gastrointestinal exotoxins synthesized by S. aureus throughout the logarithmic phase of growth or during the transition from the exponential to the stationary phase. They are active in high nanogram to low microgram quantities (24), and they are resistant to the following conditions: freezing, drying, heat treatment, and low pH, that easily destroy the bacteria that produce them and the proteolytic enzymes; hence retaining their activity in the digestive tract after ingestion. Intoxication symptoms have a rapid onset (30 min - 8 h), including nausea, violent vomiting, abdominal cramping, with or without diarrhea (23).

Staphylococcus aureus in cheeses

Contamination routes

Staphylococcus aureus may be shed directly into the milk via the udder by a diseased animal (subclinical mastitis) or may enter the milk from the external surfaces of the animals, the environment, the milking environment, equipment or from personnel (12,13,25). The factors that affect these contamination routes include: a) Animal-related factors e.g. animal health, herd size, age, and production status. b) Environment-related factors e.g. housing, feces, feed, soil, and water. c) Milking and operation of the milking equipment factors (8).

Other contamination sources are related to the cheese making environment, including equipment, personnel, water, coagulant agent or contamination between final products and raw materials (25). Cross-contamination of raw milk cheeses with S. aureus can occur through inadequate food handling practices during retail sale or at home. Unpackaged cheeses are particularly vulnerable to cross contamination from other foods and utensils. (10,11).

On the other hand, the ability of this bacterium to survive and/or grow in cheese is largely dependent on the manufacturing steps during cheese making, the physic-chemical characteristics of the cheese (pH, salt content, water activity), and the growth requirements of the microorganisms (10).

Occurrence of S. aureus and enterotoxin production in cheese

Staphylococcal food poisoning is one of the most common foodborne diseases worldwide (12). Studies on the occurrence of Staphylococcus aureus contamination in cheeses have been researched and reported. The results are summarized in Table 3.

Table 3 Studies on the occurrence of S. aureus contamination in cheeses./ Estudios sobre la ocurrencia de la contaminación por S. aureus en quesos.

| Sampling Place | Cheese Type | Country | Detection method | Detection limit (CFUg-1) | Sample size (g) | No. samples analyzed | No. positive samples | % positive samples | 95 % CI | Mean (log CFU g-1) | Level (log CFU g-1) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sale outlets | unripened cheese raw milk | Sweden | - | 100 | - | 37 | 11 | 30 | 20.3-39.7 | 1.6 | <2- >5.5 | Lindqvist |

| Sales outlets | Raw milk cheeses | Belgium | ISO 6888-1: 1999 | 100 | 10g | 71 | 41 | 29 | 22.3-35.7 | - | - | De Reu |

| Farms | fresh cheese | Belgium | ISO 6888-1: 1999 | 100 | 10g | 16 | 1 | 25 | 12.8-37.2 | - | - | De Reu |

| Retail outlets | Turkishunripened van otlu cheese | Turkey | Oxoid Manual | 100 | 10g | 50 | 50 | 100 | 72.3-127.7 | 6.1 | 2.48-7.15 | Tekinsen and Ozdemir, 2006. (29) |

| Farms | artisanal Canastra cheese | Brazil | Downes (2001) | - | 25g | 10 | 7 | 70 | 26.6-113.4 | 5.9 | <2 - 6.3 | Borreli |

| Retail | raw or thermic milk cheese | United Kingdom | Standard Microbiological Methods ( |

- | 10g | 62 | 3 | 4.8 | 3.6-6.0 | - | - | Litlle |

| Farms | goat cheese | Costa Rica | AHPA, 2001 | 100 | 10 | 15 | 3 | 20 | 9.9-30.1 | 2 | - | Araya |

| Farms | raw milk cheese | Sweden | NMKL 66.4: 2003 | 100 | 10g | 55 | 38 | 69 | 50.8-87.2 | 1.38 | <2-4.46 | Rosengren |

| Farms | artisanal fresh cheese | Cuba | NC ISO 6888-1: 2003 | 100 | 10g | 73 | 73 | 100 | 77.1-122.9 | 5.9 | 3.3-7.6 | Martínez |

| Farms | Double cream cheese | Colombia | Colombian Technical Standard 4779 | 100 | 10 | 100 | 31 | 31 | 24.9-37.1 | - | 2.0-4.0 | Herrera & Santos, 2014 (34) |

| Farms | milk, whey, cheese | Norway | NMKL 66.4: 2003 | 100 | 10g | 6 | 2 | 33 | 6.6-59.4 | 1.1 | <2-3.5 | Mehli |

| Total | - | 495 | 260 | 52.5 | 47.9-57.1 | 3.4 (1.1-6.1) | <2-7.6 | - | ||||

Table 3 shows the contamination of different types of cheeses with S. aureus. Samples were taken in farms, retail and sales outlets. The detection of S. aureus was performed using different detection methods. Four hundred ninety five cheese samples were analyzed. The percentage of positive samples was 52.5 %, with an average of 3.4 log CFU/ g and the range of counts was between <2-7.6 CFU/g.

The presence of enterotoxigenic Staphylococcus and its enterotoxins has been frequently identified in raw milk and raw milk cheeses (36). SE enterotoxins may be produced when fermentation is retarded due to the starter culture failure or when S. aureus is already present in high numbers in the milk (>104 to 105 CFU/ml) (37).

If the initial population of the enterotoxigenic strains of coagulase-positive staphylococci, mainly Staphylococcus aureus in milk is high (above 103 CFU/ml); enterotoxins may be produced before the pH drops to inhibitory levels in the cheese production (37). The intake of 20 to 1,000 ng of the enterotoxin can cause typical symptoms of S. aureus intoxication (36).

Staphylococcus aureus in Cuban artisan fresh cheeses

The research was carried out in farms of 95 artisan fresh cheese producers of six provinces of Cuba. Samples of milk, cheeses, molds and utensils used in the cheese making process were taken. Listeria spp., Bacillus cereus, Escherichia coli O157, Salmonella spp., and Staphylococcus aureus were identified; being the last one the most prevalent microorganism. Listeria monocytogenes was not identified (17).

The detection of S. aureus was performed using Rida Count Plates (R-Biopharm), which is a dry rehydratable film medium for the enumeration of Staphylococcus aureus. This method was validated by the Association of Official Analytical Chemists (AOAC), and its performance at CENLAC was evaluated according to ISO 16140 recommendations (2011), following the procedure of Martínez et al. (2013). Ten g/ml of sample were taken and the detection limit of the method was 10 CFU/g or ml. The calculations and expression of the counts resulting from Rida Count Plates were performed according to ISO-7218: 2007.

S. aureus counts in milk and cheese samples were more than 4 log CFU/ (ml or g) (Table 4). Differences in the counts of S. aureus in cheese with respect to those found in milk can be explained by the existence of other contamination sources during the production process, such as utensils, environment and personnel. These results reveal deficiencies in the manufacture of artisan cheeses, where the greatest risk is that these products are marketed fresh, with insufficient time to allow the lactic acid bacteria to be produced naturally and produce an adequate concentration of lactic acid and act as bio-preservers (Sources, 2014).

Table 4 Contamination with S. aureus in the process of artisan fresh cheese./ Contaminación con S. aureus en el proceso de queso fresco artesanal.

| Sampling n= 95 | Mean(log CFU/g o ml) sampling x cm2 | Ranger count (log CFU/g or ml) sampling x cm2 |

|---|---|---|

| Milk | 4.5± 0.8 | 3.0-6.0 |

| Farm (hands) | 1.7± 0.5 | 0.5-3.0 |

| Environment of milking | 1.4± 0.4 | 0.6-2.9 |

| Milking tank | 2.3± 0.7 | 0.7-4.6 |

| Cheese producer (hands) | 0.6 ± 0.4 | 0.1 -1.7 |

| Environment of cheese making | 1.3± 0.3 | 0.3-1.9 |

| Utensils | 2.8± 0.6 | 1.0-4.6 |

| Coagulant Agent | 2.4 ± 1.1 | 0.8- 4.8 |

| Cheese | 4.8± 0.7 | 4.0-6.9 |

| Storage Environment | 1.5 ± 0.7 | 0.3-3.0 |

Artisan processing brings with it the risk of direct manual handling to which the raw material is subjected. This favors the dissemination and growth of contaminating microorganisms, spoiling and pathogenic bacteria, which constitute a risk to the health of consumers (10).

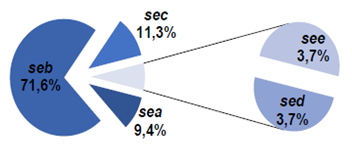

The highest risk of S. aureus is its ability to produce thermostable enterotoxins when it is found in counts greater than 1x105 CFU/ (ml o g) (36). Enterotoxin gene fragments were detected in 68.8 % of the 77 isolates of Staphylococcus aureus.

Legend: sea: enterotoxin gene SEA, seb: enterotoxin gene SEB, sec: enterotoxin gene SEC, sed: enterotoxin gene SED, see: enterotoxin gene SEE

Legend: sea: enterotoxin gene SEA, seb: enterotoxin gene SEB, sec: enterotoxin gene SEC, sed: enterotoxin gene SED, see: enterotoxin gene SEEFigure 2 Distribution of Staphylococcus aureus isolates with presence of enterotoxin gene fragments./ Distribución de aislamientos de Staphylococcus aureus con presencia de fragmentos de genes de enterotoxinas

In this study, the seb gene was the most frequently found (Figure 2). This result agrees with that reported by Hummerjohann et al. (2014), who identified SEB enterotoxin of Staphylococcus aureus as the major contaminant in Swiss cheese made from raw milk (62 %) (36).

Legal framework on cheese production in Cuba

To ensure food security of the population, the Cuban government created mandatory rules designed to control the quality of the milk and dairy products. The National Office of Standards (NC) is the National Standard Body of the Republic of Cuba, representing the country in the International Organizations and Regional Standardization. The preparation of the Cuban standards is usually performed through the Standardization Technical Committee, taking into consideration the general standards and requirements of the Codex Alimentarius. In the case of the dairy sector, a set of criteria has been established taking into consideration the requirements of the Codex in CAC/RCP 57-2004 (2009): Code of Hygienic Practice for Milk and Milk Products (38).

Some standards in Cuba are:

NC 932: 2012 Sanitary System Food. Milk and dairy. General health requirements

NC 38-04-07: 1990 Sanitary food system. Milk. Hygienic control in the milk production units

NC ISO 5538: 2010 Milk and dairy products - sampling - inspection by attributes

NC 448: 2006 Raw milk. Quality specifications

NC 585: 2015. Microbiological requirement for food. Sanitary requirement

However, there are no regulations establishing under which hygienic-sanitary conditions the artisan fresh cheeses must be produced and marketed, or if they have microbiological requirements.

Conclusions

In the present paper, aspects related to the production process of artisan fresh cheesees in Cuba are exposed. From the microbiological point of view, Staphylococcus aureus was found in concentrations close to those that have been described as enough for the production of enterotoxins, where the genes responsible for the expression of enterotoxin production were identified in 68.8 % of the isolates. It is a need to implement Good Dairy and Good Hygiene Practices in the production process as an initial approach for the implementation of Good Manufacturing Practices that contribute to a greater safety of artisan fresh cheeses.