Introduction

Musculoskeletal disorders (MSDs) are among the main occupational pathologies which affect industrial productivity, result in disabilities and decrease workers’ quality of life [1, 2, 3]. There are approximately 40 million European workers suffering from these occupational diseases and that number is on the rise, with an impact not only on public health but also on economy, affecting between 0.5% and 2% of Gross Domestic Product (GDP) [4].

The tannery workers were exposed to several hazard during the manufacturing process performing their job[5]. Working conditions, such as: inappropriate workstations, incorrect working procedures and the inappropriate use of tools are some of the ergonomic risk factors leading to the development of musculoskeletal disorders, which affect: tendons, nerves, muscles, and the skeletal system, mainly in the upper extremities, namely the shoulder, the neck and the spine [6]. MSDs can afflict 20% - 80% of the working population in a company, leading in some cases to temporary or permanent disabilities, thus causing absenteeism at work [7].

In 2018, Ecuador reported 932 cases of occupational diseases and 26 cases of professional diseases, according to the General Occupational Hazard Insurance of the Ecuadorian Social Security Institute (IESS, by its Spanish initials). However, the record of the diseases most commonly diagnosed was kept only until 2016; out of the 358 professional diseases reported, 16.1% were cases of chronic low back pain and discal hernias and 12.4% were cases of shoulder pain and tendinitis, and spine and upper extremity affections mostly [8]. The same record reveals that in 79.8% of cases, the possible causes are related to ergonomic risk factors and in 12.5% to improper cargo handling [8].

The manufacturing sector accounts for 12.53% of Ecuador's GDP, and is divided into 24 subsectors according to the Extended Classification of Economic Activities (ISIC), which include the manufacture of leather and related products, in factories known as tanneries [9, 10]. Tungurahua is a province where 54.4% of the tanning activity is concentrated, and Ambato is one of the cantons with the highest volume of tanning 1. The hides treated in tanneries have an approximate average weight of 23 - 32 kg when they are wet, so when they are not properly handled, the health of workers is affected; the loads weighing more than 3 kg, in spite of being light, entail the risk of causing lumbar affections in unfavorable ergonomic conditions [11].

When analyzing the jobs in a tannery, specifically in the pre-tanning area, which comprises the stages of: soaking, unhairing, liming, deliming and splitting, the risk factors are related to the manual handling of loads. Including the actions of: moving, dragging and pushing hides, lifting the hides to pile them up and twisting and turning movements, which leads to the development of MSDs in body regions such as the lower and upper back, the shoulders, the neck and the knees [12]. Seventy-five percent of the tasks performed by a worker in a tannery are regarded as activities involving a high risk of developing health conditions and 25% are considered moderate risk tasks [13].

Therefore, the main objective of this research is to evaluate the manual handling of loads and its impact on the musculoskeletal disorders among the pre-tanning workers of a tannery in Ambato city. Taking the results as a basis for the future implementation of: corrective measures, working conditions improvement, the reduction of absenteeism, the enhancement of productivity and the workers’ quality life.

Methods

For the evaluation of the musculoskeletal disorders caused by the manual handling of loads, to the unhairing, splitting and fleshing workers according to the risks determined for each post, the authors applied:

The Nordic-Dutch musculoskeletal questionnaire

ISO 11228-1 on the risks of manual lifting of loads (NIOSH)

ISO 11228 -2 on pushing and pulling

The Guide on load lowering and handling of the National Institute of Occupational Health and Safety (INSHT, by its Spanish initials)

According to the predominant risk factor in each workstation, the author decided to apply the aforementioned methodologies, the risk factors in the workstations of the pre-tanning area it observed in table 1.

Table 1 Risk factors in the workstations of the pre-tanning area.

| Risk factor | Methods | Workstation |

|---|---|---|

| Load pushing and pulling | ISO 11228 - 2. Pushing and pulling | Unhairing |

| Load lowering and handling | INSHT Guide | Fleshing |

| Load lifting | ISO 11228 - 1 (NIOSH) Manual lifting and carrying | Splitting |

Manual handling of loads - INSHT Guide

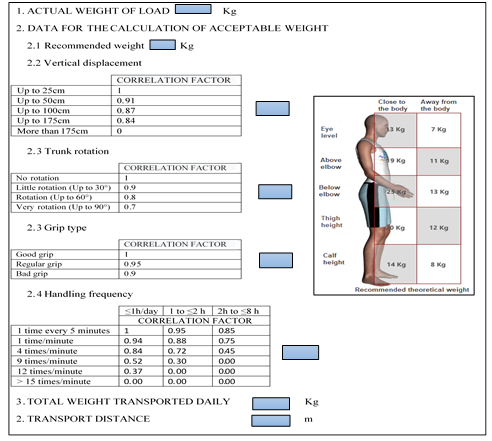

Method based on the recommendations of Royal decree 487/1997, which establishes the procedure for the assessment of risks related to the manual handling of loads [12]. In figure 1 it is reflected the collection of handling data.

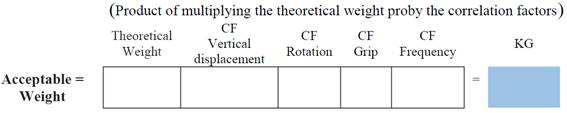

Table 2 defines the parameters that are required to determine the acceptable load weight depending on the working conditions, namely the actual weight of the load in Kg, the recommended weight in Kg and the correlation factors of vertical displacement, trunk rotation, type of grip and handling frequency. It is also necessary to specify the total weight transported daily in Kg and the distance in meters. The acceptable weight calculation it observed in the figure 2.

Table 3 presents the factors to be considered for the calculation of the acceptable weight; first of all, the recommended theoretical weight is selected and then, the weight is calculated by applying the following formula:

AW= Theoretical weight * CF vertical displacement * CFrotation * CFgrip* CFfrequency (Kg)

AW: Acceptable weight

CF: Correlation factor

It is necessary to analyze whether the actual weight of the load is greater than 25 kg or greater than the acceptable weight, in which case it is regarded as a non-tolerable risk and requires corrective actions; otherwise, it will be considered a tolerable risk.

NIOSH Lifting Equation Evaluation Method

This method allows evaluating and preventing the risks associated with tasks that involve the manual handling of loads [14]. The method takes into consideration the Biomechanical, Physiological and Psychophysical factors [15]. The purpose of this method is to obtain the Recommended Weight Limit (RWL) for a specific task from the product of multiplying seven risk factors that reduce the reference weight on the basis of the actual working conditions [16].

The NIOSH Equation calculates the Recommended Weight Limit (RWL) through the formula 1:

LC: |

Load constant |

HM: |

Horizontal distance multiplier factor |

VM: |

Height multiplier factor (vertical distance) |

DM: |

Vertical travel multiplier factor |

AM: |

Asymmetric multiplier factor |

FM: |

Frequency multiplier factor |

CM: |

Coupling multiplier facto |

ISO 11228-2 Manual handling - Part 2: Pushing and pulling

The ISO 11228-2:2007 method establishes the recommended limit values for whole-body pushing and pulling, as well as the criteria for the assessment of risk factors that are considered important to manual pushing and pulling, which allows analyzing the risks to the health of the working population [17]. In order to determine the level of risk, it is necessary to define the initial and sustained force indexes with the formula 2 and 3.

IRi |

Risk index due to initial force |

FRi |

Initial force recorded in Newtons |

LFi |

Initial limiting force, obtained from the table |

IRs |

Risk index due to sustained force |

FRs |

Sustained force recorded in Newtons |

FLs |

Sustained limiting force, obtained from table |

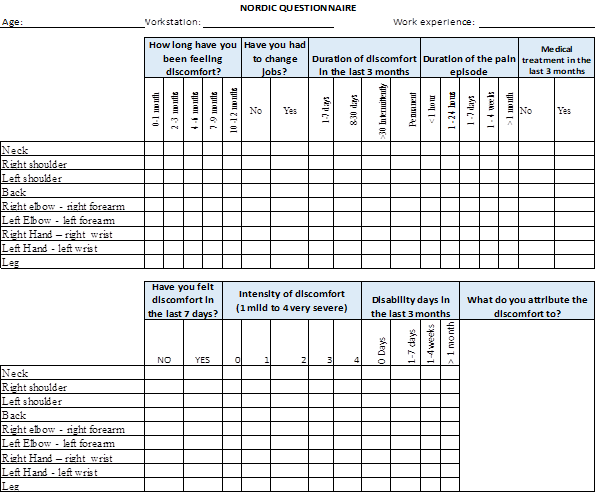

Nordic-Dutch Musculoskeletal Questionnaire

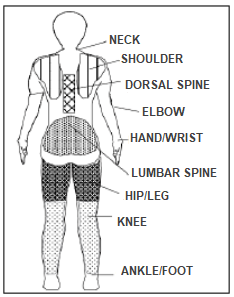

This is a standardized method for determining and analyzing the symptoms of musculoskeletal disorders and individual work-related risk factors. Its format was developed by Vincent H. Hildebrandt and it was published by TNO Work and Employment in 2001 [18]. This method assesses the presence of symptoms at muscle or bone level in nine body segments (neck, shoulders, upper and lower back, elbows, wrists, hands, knees, ankles and feet) of a working population, the regions of the body it observed in the figure 1 [19]. Taking into account the time that they have been experiencing discomfort ranging from 0 to 12 months, the duration of discomfort in the last three months, the intensity of the pain and the severity of the symptoms in relation to their effect on workers’ activities both in the workplace and during their leisure time, according to the figure 3 [20].

The Nordic questionnaire is observed in figure 4.

Results

In the unhairing workstation, after applying the methodology to analyze the risk factors associated with load pushing and pulling (cattle hides), it was observed that the IRi = 1.07 and the IRs = 1.11. Therefore, the two indices are higher than 1, so the risk level is Not Acceptable, which entails health problems among workers due to musculoskeletal disorders, it is observed in table 1.

Table 1 Results of risk assessment for load pushing and pulling.

| RESULTS OF RISK ASSESSMENT FOR LOAD PUSHING AND PULLING | |||

|---|---|---|---|

| PSYCHOPHYSICAL TABLES METHOD (ISO 11228-2) | |||

| General Information | |||

| Company: Tannery | Assessment date: 28/04/2017 | ||

| Workstation details | |||

| Area: Pre-tanning | Workstation: Unhairing of hides | ||

| Description of the activity | |||

| Pulling hides manually on foot from drum to conveyor chain. | |||

| Data | |||

| DESCRIPTION | PUSHING | PULLING | |

| a | Handle height (cm) | Not applicable | 70 |

| b | Distance over which the load is pushed or pulled (m) | Not applicable | 2 |

| c | Push / Pull Action Frequency (movements per minute) | Not applicable | 1 |

| d | Working population (male or female) | Not applicable | Male |

| e | Initial Force (N) - Measurement | Not applicable | 294.00 |

| f | Sustained Force (N) - Measurement | Not applicable | 186.20 |

| g | Initial force (N) -Table | Not applicable | 274.19 |

| h | Sustained Force (N) - Table | Not applicable | 168.06 |

| Calculations | |||

| IRi= | Initial Force | IRs= | Sustained Force |

| Maximum Initial Force | Maximum sustained force | ||

| IRi | Risk index due to initial force | Not applicable | 1.07 |

| IRs | Risk index due to sustained force | Not applicable | 1.11 |

| Risk levels | |||

| IR | Risk zone | ||

| IR ≤ 1 | Recommended or Acceptable | ||

| IR > 1 | Not Acceptable | ||

Source: Grefa (2018) [22]

For the fleshing workstation, the results of the analysis of the risk factors associated with load handling and unloading according to the INSHT Guide revealed that the actual weights handled by the worker at the fleshing stage are high both at the origin and at the destination. Where the RW (Actual Weight) is greater than the AP (Acceptable Weight), the risk level is not tolerable, it is reflected in table 2.

Table 2 Results of risk assessment based on the MMC-INSHT method.

| RESULTS OF RISK ASSESSMENT BASED ON THE MMC-INSHT METHOD | |||

|---|---|---|---|

| Origin | Destination | ||

| RW | Actual Weight of load (Kg) | 16 | 16 |

| AW | Acceptable Weight (Kg) | 3.47 | 6.44 |

| RL | Risk level | Non-tolerable risk | Non-tolerable risk |

| Risk levels | |||

| DECISION | Risk zone | ||

| RW ≤ AW | Tolerable risk | ||

| RW > AW | Non-tolerable risk | ||

Source: Grefa (2018) [22]

The results of the risk assessment for load lifting in the splitting workstation reveal that the LI = 1.40, so 1 <LI <3 and the lifting index (LI) is moderate, it is observed in Table 3.

Table 3 Results of risk assessment for load lifting.

| RESULTS OF RISK ASSESSMENT FOR LOAD LIFTING | ||||||

|---|---|---|---|---|---|---|

| Description | Weight of load (Kg) | LC (Kg) | RWL Origin (Kg) | RWL Destination (Kg) | RWL Activity (Kg) | LI |

| Lifting of hides in the splitting workstation | 10 | 23 | 7.13 | 9.12 | 9.12 | 1.40 |

| Risk level | ||||||

| DECISION | Risk zone | |||||

| LI<1 | Limited risk | |||||

| 1<LI<3 | Moderate risk | |||||

| LI>3 | High risk | |||||

Source: Grefa (2018) [22]

The Nordic MSD questionnaire was applied to six workers in the pre-tanning area. The age group was mainly within the range of 21-30 years (50%). Concerning sex, 100% of the workers survived were men. Concerning working experience, they were mostly in a range of 6 - 10 years (50%) and 2 -5 years (33%). Regarding the hours and days worked, they were 8 and 5 respectively, it is observed in table 4.

Table 4 Sociodemographic variables of pre-tanning workers in a tannery.

| Variable | Frequency | (%) |

|---|---|---|

| Age group | ||

| < 20 years old | 0 | 0% |

| 21 - 30 years old | 3 | 50% |

| 31 - 40 years old | 1 | 17% |

| 41 - 50 years old | 1 | 17% |

| 51 - 60 years old | 1 | 17% |

| > 60 years old | 0 | 0% |

| Sex | ||

| Male | 6 | 100% |

| Female | 0 | 0% |

| Working years | ||

| < 1 year | 0 | 0% |

| 2 -5 years | 2 | 33% |

| 6 - 10 years | 3 | 50% |

| 11- 15 years | 1 | 17% |

| > 15 years | 0 | 0% |

| Working hours | ||

| < 6 hours | 0 | 0% |

| 6 - 8 hours | 6 | 100% |

| > 8 hours | 0 | 0% |

| Days/weeks worked | ||

| 5 days | 6 | 100% |

The musculoskeletal disorders with the highest prevalence among pre-tanning workers were located mostly in the regions of the back (83%), neck (67%), left shoulder (67%) and hand (67%), while the least prevalent were located in the elbow and the leg (33%), as shown in table 5.

Table 5 Most prevalent MSDs among pre-tanning workers organized by body region

| Body Region | Frequency | (%) |

|---|---|---|

| Neck | 4 | 67% |

| Right shoulder | 3 | 50% |

| Left shoulder | 4 | 67% |

| Back | 5 | 83% |

| Right elbow - right forearm | 2 | 33% |

| Left Elbow - left forearm | 3 | 50% |

| Right Hand - right wrist | 4 | 67% |

| Left Hand - left wrist | 4 | 67% |

| Leg | 2 | 33% |

The duration of discomfort in the various body regions, it is observed in table 10. The troubles with the highest occurrence were identified in the back region (67%), with a duration of pain greater than 9 months, the neck (50%), with duration ranging from 0 to 1 month, the shoulder (50%) for a period greater than 9 months, the hand or wrist (33%) from 0 to 1 month and the leg (17%) from 0 to 1 month or for more than 9 months. Table 10 describes that in the last 3 months, discomfort concentrated mainly in the region of the back (83%) and the elbow/forearm (50%), followed by the neck (17%), the shoulder (17%), the hand/wrist (17%) and the leg (17%). The MSDs with the highest prevalence affected both the left and the right sides of the body: shoulder (33%), elbow - forearm (50%) and hand - wrist (50%), as reflected in table 6.

Table 6 Prevalence of MSDs over time, according to the survey Conducted.

| Time of discomfort by body region | Frequency | (%) | Last 3 months |

|---|---|---|---|

| Neck | 33% | ||

| 0 - 1 month | 3 | 50% | |

| 7 - 9 months | 1 | 17% | |

| >9 months | 0 | 0% | 33% |

| Shoulder | |||

| 0 - 1 month | 1 | 17% | |

| >9 months | 3 | 50% | |

| Back | 83% | ||

| 0 - 1 month | 1 | 17% | |

| >9 months | 4 | 67% | |

| Elbow - Forearm | 33% | ||

| 0 - 1 month | 1 | 17% | |

| 2 -3 months | 1 | 17% | |

| >9 months | 1 | 17% | |

| Hand - wrist | 50% | ||

| 0 - 1 month | 2 | 33% | |

| 7 - 9 months | 1 | 17% | |

| >9 months | 1 | 17% | |

| Leg | 33% | ||

| 0 - 1 month | 1 | 17% | |

| >9 months | 1 | 17% |

The prevalence of MSDs according to the side in which workers is observed in table 7.

Table 7 Prevalence of MSDs according to the side in which workers experienced discomfort.

| Side affected | Left | % | Right | % | Both | % |

|---|---|---|---|---|---|---|

| Shoulder | 1 | 17% | 1 | 17% | 2 | 33% |

| Elbow - Forearm | 1 | 17% | 0 | 0% | 3 | 50% |

| Hand - wrist | 2 | 33% | 0 | 0% | 3 | 50% |

The most prevalent MSDs in the last 3 months were characterized by a duration of discomfort from several days to permanent ailments, as shown in table 8. The body regions affected for the longest periods were the back with permanent discomfort (50%), followed by the left elbow-forearm from 1 to 7 days (33%) and the hand-wrist from 1 to 7 days (33%). With respect to the intensity of the pain experienced, out of the total sample evaluated, 17% to 67% reported a very high intensity of discomfort, 17% to 33 %, a high intensity, and 17 %, a moderate intensity. Out of the body regions analyzed, those with the highest frequency of intensity were the back (67%) and the left shoulder (50%), reporting severe pain.

Table 8 Duration of discomfort in the last 3 months and assessment of the intensity of discomfort

| 1-7 days | 8-30 days | >30 days intermittently | Permanent | 1 Low | 2 Moderate | 3 High | 4 Very high | |

| 1 | 1 | 1 | 1 | 1 | ||||

| 17% | 17% | 17% | 17% | 17% | ||||

| 1 | 1 | |||||||

| 17% | 17% | |||||||

| 1 | 1 | 1 | 1 | 1 | 3 | |||

| 17% | 17% | 17% | 17% | 17% | 50% | |||

| 1 | 1 | 3 | 1 | 4 | ||||

| 17% | 17% | 50% | 17% | 67% | ||||

| 1 | 1 | |||||||

| 17% | 17% | |||||||

| 2 | 1 | 1 | ||||||

| 33% | 17% | 17% | ||||||

| 1 | 1 | 2 | ||||||

| 17% | 17% | 33% | ||||||

| 2 | 1 | 2 | 1 | |||||

| 33% | 17% | 33% | 17% | |||||

| 1 | 1 | 2 | 2 | |||||

| 17% | 17% | 33% | 33% | |||||

Discussion

According to this study and the numerous investigations carried out, they are proved that industrial workers are the most likely to suffer from musculoskeletal disorders. The tanning industry is considered as high risk for the development of MSDs [23]. Despite technological advances, the reality of this industry is that the processes still require manual work, which implies overexertion, forced postures and handling of heavy loads.

This study reveals novel results and provides important data on the MSDs suffered by the workers in the pre-tanning area of the leather industry, linked to the work conditions. The findings of this research show that the force exerted by the worker when pulling loads for the unhairing stage carries a risk, since the application of the ISO 11228-2 method indicates that the indexes IRi = 1.07 and IRs = 1.11 are values greater than 1, thus evidencing an unacceptable level of risk.

For example, in an ergonomic risk analysis of the manual handling of loads in a body shop company, where different methodologies were applied, including the ISO 11228 -2, applied in this study. It was determined that in four of the workstations related to the preparation of materials, the risk level was slightly dangerous for 42.86% of workers, dangerous for 28.57% and highly dangerous for 28.57% [24]. the high risks are occasioned by heavy loads and moving items manually, which have been reported as the potential contributors for MSDs [25].

Exceeding the recommended limits to pull a load represents a potential risk of causing damage and discomfort at the level of the spine, shoulders, arms and wrist, mainly due to the excessive force required to manually move heavy loads. In addition to the different heights at which the load is handled, it forces the worker to force the spine when tilting and pulling the load, the force that the worker must maintain for a certain time to cover the established distance and for an 8-hour work day.

In the case of fleshing, the ergonomic risk factor is generated by the unloading and handling of hides. By applying the INSHT technical guide for the assessment of risks due to the manual handling of loads, it was obtained that the RW = 16 kg> AW = 6.44 kg, so the risk level is not tolerable, intensifying the strain on the spine and the fatigue of the arms when performing movements above the shoulders. As mentioned in a study conducted in a warehouse of the retail sector in Arequipa - Peru, the warehouse salesman and warehouse operator posts present a non-tolerable risk level for loads greater than 3 kg, as the working conditions are unfavorable for the manual movement of hides, in terms of space, lighting and training [26].

To assess the load lifting index in the splitting post, it is applied the ISO 11228-1 method (NIOSH method) and obtained that the Lifting Index (LI) is 1.40, whose value is greater than 1 but less than 3, so the risk level is moderate, mainly due to trunk rotations between 30 ° and 70 ° and a handling height of 135 cm. As revealed a study carried out at Tenería Díaz CIA LTDA, the splitting post carries a moderate risk level (LI = 2.52) [14]. The lifting heavy items and performing the same or similar tasks repetitively increase the potential of musculoskeletal disorder suffering [27]. In this study work conditions an experience, working hours, weight of load and manual lifting heavy hides involves the risk of musculoskeletal disorders in areas such as the lower and upper back, the shoulders, the hips, and the knees, which may result in low back pain, sciatica, discal hernias, scoliosis, muscle pain and so on.

With respect to the Nordic musculoskeletal questionnaire applied, 100% of the workers in the leather industry reported ailments in various body regions, but mainly in the back (83%). As reported by Tacuri Patricia in a study on the MSDs of a sample of 24 operators from an industry, 100% of them presented musculoskeletal discomfort, mostly in the lumbar region [28]. Similar to the research carried out by the Institute of Biomechanics of the University of Valencia specifies that the affections in the lumbar segments of the spine are associated with the manual handling of loads, in spite of the automation and modernization of the industrial sector. This research also mentions that back injuries are painful, hinder mobility, lead to medical leaves and are one of the causes of early disability [29].

The disorders with the highest prevalence were those located in the back (67%) with pain lasting more than 9 months, followed by those located in the neck (50%) with a duration from 0 to 1 month and the shoulder (50%) for more than 9 months. In the case of the disorders reported in the last 3 months, they were most frequent in the back (83%).

Limitation of the research includes the small sample size to which the different types of methods and corresponding survey were applied. Similarly, the research covers only risks from manual handling of loads, excluding other ergonomic risk factors such as repetitive movements and forced postures. Another limitation that can be pointed out is the accuracy of the instrument used, the Nordic questionnaire, with respect to the medical assessment. In addition, the study did not consider the quality of life and psychological aspects that can lead to musculoskeletal disorders. Nevertheless, a reality of the work environment is demonstrated in a more specific way.

Conclusions

In conclusion, two out of three posts analyzed reveled a high level of risk related to ergonomics hazard, which caused musculoskeletal discomfort.

As a results, 100% of the pre-tanning workers studied presented ailments at muscular and bone level in various body regions, mostly in the back - spine, the neck and the shoulders, and the age of the operators most afflicted by the MSDs ranged from 21 to 30 years old.