Mi SciELO

Servicios Personalizados

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista Ciencias Técnicas Agropecuarias

versión On-line ISSN 2071-0054

Rev Cie Téc Agr vol.23 no.1 San José de las Lajas ene.-mar. 2014

ARTÍCULO ORIGINAL

Two-phase anaerobic digestion of coffee wet wastewater: Effect of recycle on anaerobic process performance

Digestión anaerobia en dos fases de las aguas residuales del beneficiado húmedo de café: el efecto de la recirculación en el funcionamiento del proceso anaerobio

Dr.C. Yans Guardia PueblaI, Dr.C. Suyén Rodríguez PérezII, Ing. Yennys Cuscó VaronaI, M.C. Janet Jiménez HernándezIII, Dr.C. Víctor Sánchez GirónIV

I Universidad de Granma (UDG), Departamento de Ciencias Técnicas, Bayamo, Cuba.

II Universidad de Oriente (UO), Centro de Estudios de Biotecnología Industrial (CEBI), Santiago de Cuba.

III Universidad de Sancti Spíritus, Centro de Estudios de Energía y Procesos Industriales, Sancti Spíritus, Cuba.

IV Universidad Politécnica de Madrid (UPM), Escuela Técnica Superior de Ingenieros Agrónomos (ETSIA), Madrid, España.

ABSTRACT

The present work shows the results of the two-phase anaerobic digestion assessment for the treatment of coffee wet wastewater. The effect of recycle on the anaerobic digestion process was studied. Twooverall organic loading rate (OLR) values of 4,2 and 5,7 kgCOD·m-3·d-1, with same overall hydraulic retention time (HRT) of 21,5 h was evaluated.In a two-phase system wereapplied two recycle rate of 0,4 and 1,0, of the effluent of an UASB-UAF methanogenic hybrid reactor towards an UASB acidogenic reactor. In the anaerobic system with a recycle rate of 1,0 the total chemical oxygen demand (COD) removal was 90%. The introduction of the recycle decreased the concentration of total volatile fatty acids (VFA), but it did not affect their composition, suggesting that the degradation pattern did not change. The presence of the acidogenic reactor in the two-phase system improved the stability of the anaerobic digestion process and increased the efficiency of methanogenic digester.

Key words: anaerobic digestion, coffee wet wastewater, recycle, two-phase system, hybrid reactor.

RESUMEN

El presente trabajo muestra los resultados de la evaluación de la digestión anaerobia en dos fases para el tratamiento de las aguas residuales del beneficiado húmedo de café. Se estudió el efecto de la recirculación en el proceso de digestión anaerobia. Fueron evaluados dos valores de cargas orgánicas volumétricas (COV) generales de 4,2 y 5,7 kgCOD·m-3·d-1, con los mismos tiempo de retención hidráulica (TRH) generales de 21,5 horas. En el sistema en dos fases fueron aplicadas dos tasas de recirculación de 0,4 y 1,0, del efluente de un reactor híbrido metanogénico UASB-UAF hacia un reactor acidogénico UASB. En el sistema anaerobio con una tasa de recirculación de 1,0, la eficiencia de eliminación de la demanda química de oxígeno (DQO) fue del 90%. La introducción de la recirculación disminuyó la concentración de los ácidos grasos volátiles (AGV), pero no cambió su composición, lo que indica que el patrón de degradación de esos ácidos no cambió. La presencia de un reactor acidogénico en un sistema en dos fases mejora la estabilidad del proceso de digestión anaerobia u aumenta la eficiencia del digestor metanogénico.

Palabras clave: digestión anaerobia, aguas residuales de café, recirculación, sistema en dos fases, reactor híbrido.

INTRODUCTION

The anaerobic digestion is a fundamental process that combined with other appropriate methods, either aerobic or physical-chemical, can be a suitable and sustainable technology to treat waste in developing countries. The microbiology of the anaerobic digestion is a complex ecosystem that involves several groups of microorganisms. In the first stage (hydrolysis), the complex organic polymers (polysaccharides, proteins and lipids) are hydrolyzed to organic compounds more simple and soluble (sugars, amino acids and fatty acids). The acidogenesis and acetogenesis are the second and third phases, respectively, where the intermediate groups are degraded by the acidogenic microorganisms forming volatile fatty acids (VFA) which are later on converted into acetate (CH3COOH), carbon dioxide (CO2) and hydrogen (H2) by the acetogenic bacteria. Finally, in the fourth phase (methanogenesis), the methane is originated by the methanogenic population (acetoclastic and hydrogenotrophic bacteria) due to the acetate conversion and by the H2-CO2 route, respectively (Pavlostatis, et al., 1991).In the conventional process, the forming-VFA microorganisms and forming-methane microorganisms stay together inside a reactor, where a delicate balance among those bacteria groups must exist, since both groups differ widely in physiological terms, nutritional needs, growth kinetic and sensitivity to the environmental conditions (Yang, et al., 2003; Dareioti, et al., 2009).

Ghosh and Pohland were the first in suggesting the physical separation of the forming-acids and forming-methane microbial populations in two separated reactors where the optimal conditions for each microorganism group are established, improving, therefore, the stability and control of the process (Pohland and Ghosh, 1971). The first reactor would be used for the VFA production and the second reactor for the methane production. This configuration overcomes the restriction of the conventional method of the anaerobic digestion, increasing the robustness of the system, and facilitating a better application, control and optimization of the process (Dareioti, et al., 2009). In addition, it allows the selection and enrichment of the different groups of microorganisms in each separated reactor, increasing the stability of the process by a better control of the acidogenic phase while preventing the overload and inhibition by toxic compounds (Caramillo and Rincon, 2012). The recycle of the effluent treated in the methanogenic reactor towards the acidogenic reactor is a method that facilitates the hydrolysis of the organic matter in the two-phase anaerobic digestion. Similarly, it improves the extraction conditions of the organic matter and, at the same time, the produced buffer capacity prevents the excessive acidification in the reactor (Stabnikova, et al. 2008). This method provides the dilution of the polluting organic load to the anaerobic reactor and the reuse of the alkalinity produced in the process in the acidification reactor. On the other hand, as the pH of the affluent in this phase can be partially controlled there is a possibility of reducing the operational costs thanks to a decrease in the amount of extra alkalinity added to the system (Azbar, et al., 2001; Demirel and Yenigün, 2002; Kraemer and Bagley, 2005).

As it has been exposed in the previous lines, the recycle of part of the effluent of a methanogenic reactor to the hydrolysis-acidification reactor in the two-phase anaerobic digestion system is a fundamental step to obtain the optimization of an anaerobic process.Furthermore, economic savings can be achieved because the demand of buffer substances for adjusting the pH of the wastewater entering the digester decreases. In consequence, the aim of this work was to assess the operation response of a two-phase anaerobic digestion system under recycle of part of the effluent of the methanogenic reactor towards the acidification reactor.

MÉTODOS

Reactors

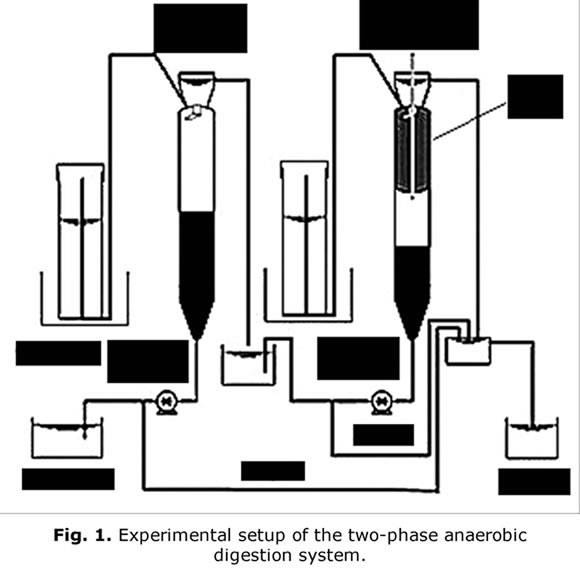

Figure 1 shows a scheme of the configuration of the laboratory scale anaerobic system that was used, which consisted of two reactors that constituted the anaerobic process. The reactors were kept at mesophilic temperature (37±1ºC) in a constant-temperature room. Two-phase anaerobic digestion system consisted of a UASB reactor for hydrolysis-acidification phase and a hybrid UASB-UAF reactor for acetogenesis-methanogenesis phase. In this system, the first reactor was a glass cylindrical reactor, of 0,35 m of height and 0,076 m of diameter and nominal volume of 2,13 L. This reactor was equipped with a Masterflex® L/S® variable-speed modular drive (model HV-07553-75, 6-600 rpm). The second reactor was based on another glass cylinder of 0,43 m of height and 0.076 m of diameter and nominal volume of 2,0 L. This other reactor was fed with a Masterflex® L/S® variable-speed modular drive (model HV-07553-80, 1-100 rpm). In the upper third of the hybrid methanogenic reactor were placed 0,67 L of crushed and sieved zeolite, with a particles diameter between 2,0-4,76 mm and filter height of 0,14 m.

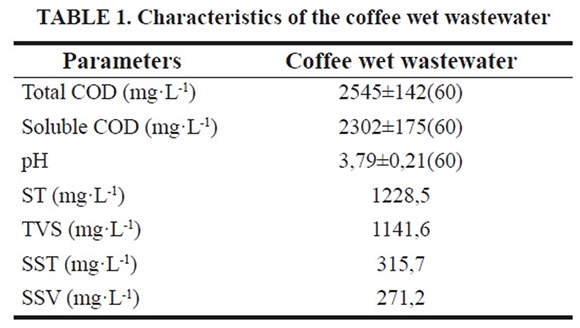

Feed and seed

The inoculum used was granular sludge coming from an industrial scale UASB reactor that processed canned juice wastewaters having a volatile suspended solid (VSS) concentration of 73,5 g·L-1. The laboratory reactors were fed with coffee wet processing wastewater, located in Ixhuatlán community, Veracruz, Mexico. The composition of the wastewater is shown in Table 1. As the coffee wet processing wastewater was acid its pH had to be adjusted using sodium bicarbonate (NaHCO3).

Experimental procedure

The hydrolytic-acidogenic phase reactor and the acetogenic-methanogenic phase reactor of the two-phase system were inoculated, respectively, with 0,64 and 0,4 L of the granular sludge already mentioned. Once the inoculation was completed the start-up phase took place. The start-up of the two-phase system lasted three weeks. When concluding the three week it was considered that the systems had quasi-stationary state conditions, so two recycle rates, 0,4 and 1,0, in a cycle of three weeks each one, were evaluated and denominated Run1 and Run2. The characteristics of the different evaluation conditions are detailed in Table 2. Each OLR evaluation was carried out in a period of 3 weeks. With the aim of increasing the alkalinity available to deliver to the first reactor it was established an internal recycle rate of 0,2 in the second reactor.

Analytical methods

The alkalinity ratio (α) was calculated as the quotient of partial alkalinity at pH 5,75 and total alkalinity at pH 4,30. Total and soluble chemical oxygen demand (COD) analyses were carried out using a HACH COD reactor (digestion at 150ºC for 2 h) according to the closed reflux colorimetric method described in Standard Methods for the Examination of Water and Wastewater (APHA, 1995). Volatile Fatty Acids (VFA) were analyzed with a gas chromatograph (Chromatograph SRI model 8610, with a flame detector, Zebron column, and Helium gas carrier to 30 psi). The biogas production was daily quantified by displacement of the liquid column placed in each of the reactors gas meters. The methane concentration in biogas was measured by gas chromatography (Chromatograph Fisher Gas Partitioner Model 1200, equipped with a detector of thermal conductivity, double column Porapack Q and mesh molecular SA, with Helium gas carrier flow of 25 mL·min-1).

RESULTS AND DISCUSSION

UASB reactor for the hydrolysis-acidogenesis phase Figure 2a shows the evolution of the pH in the effluent of the acidogenic reactor. During the start-up stage, the system showed an average pH value in the effluent of 6,25±0,21, once the pH of the wastewater to be treated was adjusted to an initial value of 6,5. These conditions provided an adequate acclimatization of theacidogenic bacteria in the start-up stage, thus achieving an adequate substrate for the methanogenic bacteria of the next phase. Because a pH of 6,0 was the objective to reach in the effluent of the acidogenic stage, the pH of the wastewater to treat was reduced during the Run1 assessment to values of 6,0 and 5,6 in two consecutive stages (Figure 2a). For this purpose part of the methanogenic effluent was recycled toward the first reactor. When the recycle was induced, a larger hydraulic load having a pH close to 8,0 coming from second reactor enters to the first reactor, causing an eventual increase in H+ concentration in this last reactor, that resulted in an increase of the alkalinity in the system. According to Romli,et al., (1994), the recycle effect influences the conversion of CO2 dissolved to CO2 gaseous, which reduces the consumption of an alkali substance to adjust the pH. Thus, in a two-phase anaerobic system in steady-state conditions the use of an appropriate recycle flow will maintain to a minimum the total operating costs. In Run1 the recycle ratio was 0,4 and it rose up to 1,0 in Run2. For this reason two other pH drops to values of 5,5 and 5,4 were carried out in days 50 and 57, respectively. This pH decrease resulted in an effluent pH interval whose range was 5,80-6,13, and an average value of 6,06±1,17. This pH interval is very close to the interval reported as optimal in the literature, because it provides suitable environmental conditions for the hydrolytic-acidogenic bacteria, besides providing a stable substrate for the methanogenic phase (Bouallagui, et al., 2004; Demirer, et al. 2004, Ponsa, et al., 2008).

As it is observed in the Figure 2b, the recycle did not have a significant effect in the alpha index, because there were not significant differences between the average values observed in the two recycle ratios. When all the data measured in Run1 and Run2 were considered, the alpha index mean value was 0,27±0,02, and the alkalinity mean value was 837 mgCaCO3·L-1. Such low alpha index and alkalinity mean values were expected since the purpose of the acidogenic phase is the VFA production. Therefore, the high concentrations of VFA in this reactor were responsible for the low mean values of those two variables (Leitão, et al., 2006; Perez and Torres, 2008). Figures 2c and 2d show the VFA concentrations and the COD removal efficiency behavior in the effluent of the acidogenic reactor for the two recycle rates evaluated. The compounds that resulted in this second experiment with recycle were acetic acid (55-56%), propionic acid (34-35%) and butyric acid (9-11%), and their respective concentrations were 388-418 mg·L-1, 243-261 mg·L-1 and 65-85 mg·L-1. On the other hand, the interval of the COD removal efficiency varied within the range of 32-38% for both conditions (Run1 and Run2), and the average acidification degree was 35±3%. The analysis of each VFA group showed that the recycle did not influence in the relative composition of them, indicating that the recycle did not affect the degradation pattern of the residual. Romli et al. (1994) observed a similar situation and they reported that the increase of the recycle has the effect of diluting the VFA and the wastewater concentration to treat. Biogas production and methane concentration are observed in the Figure 2e. The biogas production and methane concentration achieved average values of 0,72±0,17 m3·kgCOD-1rem·d-1 and 15±1,7%, respectively.

Hybrid UASB-UAF reactor for the acetogenic-methanogenic phase

Effluent pH values of the methanogenic reactor were observed in the interval of 7,68-8,03, with an average value of 7,9±0,3 (Figure 2a). This pH interval allows concluding that an appropriate performance of the methanogenic phase was achieved. Alpha index values were measured in a range of 0,55-0,68 (Figure 2b) and the total alkalinity mean value was 1231±93 mgCaCO3·L-1. The main pH buffer compounds in an anaerobic reactor are the alkalinity produced by ions bicarbonates (titration until pH 5,75) and the VFA (titration until pH 4,3) (Hass, and Adam, 1995). The limiting steps of this two-stage treatment were the last two phases of the anaerobic process (acetogenesis and methanogenesis) because this agro-industrial wastewater consisted of high carbohydrate concentrations. Taking into account the values of total alkalinity reached, they provided adequate buffering capacity to prevent any VFA accumulation and the imbalance of the system. A factor that affects an anaerobic system is the organic overload generated by the frequent variation in the amount and concentration of this sort of wastewaters due to the variability of the coffee grain harvest. This phenomenon hampers OLR control, inducing a potential risk of overloading the anaerobic reactor by the application of an OLR higher than the one applied initially.

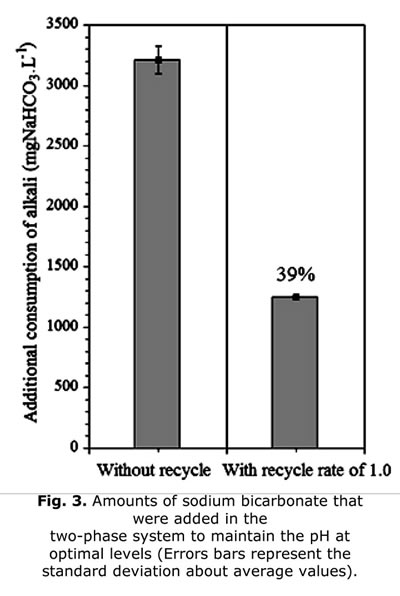

The effluent recycle from the methanogenic reactor towards the acidogenic reactor reduced the sodium bicarbonate consumption required in the latter to increase the pH of the incoming wastewater. In Figure 3 can be seen the amounts of sodium bicarbonate that were added in the acidogenic reactor to maintain the pH at optimal levels. A decrease of 39% in the sodium bicarbonate consumption was reached by the two-phase system with the recycle rate of 1,0, because it increased the alkalinity in the acidogenic reactor. These results confirm that the recycle enables to decrease the operation costs in a two-phase anaerobic system, due to smaller alkalinity consumption. This observation agrees with what has been reported by other authors. For example, in a study carried out by Kida and Sonoda (1992), the alkalinity consumption decreased from 2,6 g L-1 to 2,2 g·L-1 with the introduction of the effluent recycle from the gasification reactor to the liquefaction reactor, with the use of CSTR and AFBR reactors for the acidification and methanogenesis stages, respectively. According to Romli, et al., (1994), an increase of the recycle rate is inversely proportional to the decrease of the additional alkalinity consumption in an anaerobic reactor. Therefore, the effluent recycle allows decreasing the use of an alkaline substance, so it influences significantly in the operation cost of an anaerobic system.

Average acetic and propionic acid concentrations in the effluent were of 76±21 mg L-1 and 43±7 mg·L-1, respectively, whereas the butyric acid concentration was below the chromatograph detection limit. It was observed a tendency toward a decrease of the VFA concentration with the introduction of recycle (Figure 2c), indicating that the anaerobic methanogenic microorganisms were stimulated by this factor because the amount of VFA degraded was higher than without recycle. Recycle allows a better distribution of the anaerobic bacteria, a higher dispersion of the metabolic products produced, and a greater nutrient diffusion. Observed VFA concentration values were lower than the VFA levels reported as inhibitory of the methanogenic bacteria (Wang, et al., 2009). Therefore, the environmental conditions existing in the methanogenic reactor were adequate for the fast conversion of intermediate products of the anaerobic metabolism.

A beneficial effect of the recycle in terms of the organic polluting degradation was observed. The average total COD removal was 90±1%, while for the soluble COD removal it was 93,2±0,87% (Figure 2d). In the hybrid reactor UASB-UAF, the development of a microbial biofilm attached to an inert medium (zeolite) produced a greater retention of active biomass, thus enhancing stability in the two-phase system. Other authors have reported similar results (Parawira, et al., 2006; Zinatizadeh, et al., 2006 a,b; Singh and Prerna, 2009; Selvamurugan, et al., 2010). Recycle also allowed the increase of the applied OLR in the anaerobic system in two-phases. An increase of the OLR of up to 5,7 kgCOD·m-3·d-1 did not affect the performance of the process, maintaining high degradation efficiencies of the organic matter (Figure 2d). Several authors have confirmed that the methanogenic hybrid UASB-UAF reactor is very efficient in retaining high amounts of biomass under conditions of applied organic overload (Zinatizadeh, et al., 2006 a,b; Singh and Prerna, 2009).

The average total biogas production in the methanogenic reactor of the two-phase system was 0,13±0,02m3·kgCOD-1rem·d-1. In Run1, when a recycle rate of 0,4 in the acidogenic reactor was considered, the methane concentration in the biogas produced varied in an interval of 59-67%; whereas increasing the recycle rate to 1.0 in the same reactor, the methane concentration decreased to 52-59%; which indicated that the increase in the recycle rate decreased the methane concentration in the biogas. According to Romli et al. (1994), an increase in the recycle rate eventually increases the CO2 production in the biogas.

CONCLUSIONS

In the two-phase anaerobic digestion system, recycle cased an alkalinity reutilization that resulted in a rise in the pH of the acidogenic reactor.

There circulation did not affect the VFA production in the acidogenic anaerobic reactor, but reduced its concentration in the effluent.

Total and soluble COD removal efficiency in the two-phase system was higher, reaching values above 90%.

In the two-phase system with a recycle rate of 1,0 from the acidogenic reactor to the methanogenic reactor, the consumption of sodium bicarbonate was 39% lower than same conditions without recycle. Recycle increased the OLR applied in the two-phase system without being affected the COD efficiency removal, but at the expense of a decrease in the concentration of methane in the biogas.

ACKNOWLEDGEMENTS

The authors would like to thank the support from Dr. Adalberto Noyola-Robles, Dr. Juan Morgan-Sagastume,M.Sc. Margarita Cisneros and Ing. Roberto Briones, technicians at UNAM (Mexico D.F., Mexico),The support of Agro-Industrias Unidas de México S.A. is gratefully acknowledged. The senior author would like to thanks the SEP of Mexico and the UPM (Madrid, Spain) the scholarships granted.

Nota: La mención de marcas comerciales de equipos, instrumentos o materiales específicos obedece a propósitos de identificación, no existiendo ningún compromiso promocional con relación a los mismos, ni por los autores ni por el editor.

REFERENCIAS BIBLIOGRÁFICAS

1. AZBAR, N., URSILLO, P., SPEECE, R.: Effect of process configuration and substrate complexity on the performance of anaerobic processes, Wat. Res., No. 35: 817-829: 2001.

2. BOUALLAGUI, H., TORRIJOS, M., GODON, J., MOLCTTA, R., CHEIKH, R., TOUHAMI, Y., DELGENES, J., HAMDI, M.: Two-phase anaerobic digestion of fruit and vegetable wastes: Bioreactors performance, J. Biochem. Eng., (21): 193-197, 2004.

3. CARAMILLO, R., RINCON, J.: Effect of inhibitory compounds on the two-phase anaerobic digestion performance of diluted wastewaters from the alimentary industry, Chem. Eng. J., (193-194): 68-76, 2012.

4. DAREIOTI, M., DOKIANAKIS, S., STAMATELATOU, K., ZAFIRI, C., KORNAROS, M.: Biogas production from anaerobic co-digestion of agroindustrial wastewaters under mesophilic conditions in a two-stage process, Desalination, (248): 891-906, 2009.

5. DEMIRER, G., CHEN, S.: Effects of retention time and organic loading rate on anaerobic acidification and biogasification of dairy manure, J. Chem. Technol. Biotechnol., (79): 1381-1387, 2004.

6. HASS, D., ADAM, N.: Use of a simple titration procedure to determinate H2CO3 alkalinity and volatile fatty acids for process control in waste-water treatment, Water SA, (21): 307-318, 1995.

7. KIDA, K., SONODA, Y.: Treatment of coffee waste by slurry-state anaerobic digestion, J. Ferment. Bioeng., (69): 354-359, 1992.

8. KRAEMER, J., BAGLEY, D.: Continuous fermentative hydrogen production using a two-phase reactor system with recycle, Environ. Sci. Technol., (39): 3819-3825, 2005.

9. LEITÃO, R., HAANDEL, A., ZEEMAN, G., LETTINGA, G.: The effects of operational and environmental variations on anaerobic wastewater treatment system: A review, Bioresour. Technol., (97): 1105-1118 2006.

10. PARAWIRA, W., MURTO, M., ZUAUYA, R., MATTIASSON, B.: Comparative performance of a UASB reactor and an anaerobic packed-bed reactor when treating potato waste leachate, Renew. Energy., (31): 893-903 2006.

11. PAVLOSTATHIS, S., GIRALDO-GOMEZ, E.: Kinetics of anaerobic treatment: a critical review, Crit. Rev. Environ. Control, (21): 411-490, 1991.

12. PEREZ, A., TORRES, P.: Índices de alcalinidad para el control del tratamiento anaerobio de las aguas residuales fácilmente acidificables, Ingeniería Sanitaria, (10): 41-52, 2008.

13. POHLAND, F., GHOSH, S.: Developments in anaerobic stabilization of organic wastes: The two-phase concept, Envir. Letters, (1): 255-266, 1971.

14. PONSA, S., FERRER, I.., VAZQUEZ, F., FONT, X.: Optimization of the hydrolytic-acidogenic anaerobic digestion stage (55ºC) of sewage sludge, Wat. Res., (42): 3972-3980, 2008.

15. ROMLI, M., GREENFIELD, P., LEE, P.: Effect of recycle on a two-phase high-rate anaerobic wastewater treatment system, Wat. Res., (28): 475-482, 1994.

16. SELVAMURUGAN, M., DORAISAMY, P., MAHESWARI, M.: An integrated treatment system for coffee processing wastewater using anaerobic and aerobic process, Ecological Engineering, (36): 1686-1960, 2010.

17. STABNIKOVA, O., XUE-YAN, L., JING-YUAN, W.: Anaerobic digestion of food waste in a hybrid anaerobic solid-liquid system with leachate recirculation in an acidogenic reactor, Biochem. Eng. J., (41): 198-201, 2008.

18. WANG, Y., ZHANG, Y., WANG, J., MENG, L.: Effects of volatile fatty acid concentrations on methane yield and methanogenic bacteria, Biomass & Bioenergy, (33): 848-853, 2009.

19. YANG, K., YU, Y., HWANG, S.: Selective optimization in thermophilicacidogenesis of the cheese-whey wastewater to acid acetic and butyric acids: partial acidification and methanation, Wat. Res., (37): 2467-2477, 2003.

20. ZINATIZADEH, A., MOHAMED, A., ABDULLAH, A., MASHITAH, A., ISA, M., NAJAFPOUR, D.: Process modeling and analysis of palm oil mill effluent treatment in an up-flow anaerobic sludge fixed film bioreactor using response surface methodology (RMS), Wat. Res., (40): 3193-3208, 2006.

21. ZINATIZADEH, A., MOHAMED, A., NAJAFPOUR, D., ISA, M., NASROLLAHZADEH, H.: Kinetic evaluation of high rate POME digestion in an UASFF bioreactor, Process Biochem., (41): 1038-1046, 2006.

Recibido: 20 de mayo de 2012.

Aprobado: 5 de septiembre de 2013.

Yans Guardia Puebla. Universidad de Granma (UDG), Departamento de Ciencias Técnicas, Carretera Manzanillo, km 17 ½, Peralejo, Bayamo, CP 85100, Cuba. Correo electrónico: yguardiap@udg.co.cu