Introduction

The techniques of evaluation and improvement of irrigation systems allow knowing the parameters involved in the application of water, based on field tests carried out under normal working conditions, as well as determining the precise changes to improve the irrigation process (Ucker et al., 2013). With these changes, it is possible to achieve savings in water, labor, energy, etc., an improvement in crop yields and the reduction of erosion risks and soil and groundwater contamination (Ouazaa et al., 2013).

The management stage consists in the establishment of irrigation schedules, the operation of the system according to such calendars and the maintenance thereof. Irrigation schedules in a well-managed system are developed mainly based on the water demands of the crop generated by climatic conditions (Agilar, 2013; Vélez et al., 2013).

Micro-irrigation systems require more technical capacity than other pressurized irrigation systems. Modern micro-irrigation is a water management and nutrition system (Valipour, 2014). The lack of exhaustive agricultural research and field experience in many locations is sometimes a problem for the designer. In addition, the lack of trained personnel for its operation can lead to failures in well-designed and installed systems (Rodríguez et al., 2014).

More than 40 years ago, the first micro-irrigation systems were commercially established in Cuba, benefiting mainly citrus, banana, fruit, sugarcane and vegetable crops (Carmenates-Hernández et al., 2017a). It cannot be ignored that micro-irrigation has provided yield increases of around 30-50% in the beneficiary crops with savings of 30-40% of water and 20-30% of energy, however, high capital investments are required to its establishment (Carmenates-Hernández et al., 2017b).

At present, numerous leading commercial companies, dedicated to sale components of micro-irrigation systems, are located in Cuba, which allows accessing to the most advanced technologies. It is clearly one of the contributing factors, in certain measure, to the rapid expansion of areas under irrigation with these technologies in the last 10-15 years (Carmenates-Hernández et al., 2014). This brings with it new technological problems, among them: a) Emitters that are used in micro-irrigation systems are not previously evaluated and there are no specialized laboratories in the country for hydraulic and mechanical evaluation, nor standardized methodologies that enable determine and certify its quality; b) The technical preparation of the personnel in charge of the management and operation of the micro-irrigation systems is insufficient; c) Sometimes it is not possible to maintain a section of adequate dimensions in the root zone of the plant in which moisture close to the field capacity is maintained and d) The quality of groundwater is not evaluated in terms of the high content of calcium and magnesium carbonate, which results in the obstruction of the emitters (Carmenates-Hernández et al., 2016). Therefore, the objective of this work was to propose a methodology to improve the management of micro-irrigation systems in Ciego de Ávila Province, which contributes to a better functioning of these systems.

Methods

The research was carried out in University of Ciego de Ávila and in areas of UBPC “El Tezón” belonging to “Ceballos” Agroindustrial Company, in the cultivation of guava with a typical Red Ferrallitic soil. The methodology used for the evaluation of dripper-type emitters was established in the International Standard ISO 9260 (1991) entitled Irrigation Equipment for Agriculture Drippers - Specifications and test methods (ISO. 9260, 1991). The emitters selected for the study were those found in the irrigation systems of UBPC “El Tezón”.

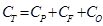

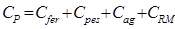

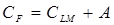

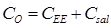

To determine the influence of water quality on the seals, the physical-chemical analyzes of the wells that supply the areas where the research was performed, were carried out according to the classification of water quality for irrigation of FAO (2013) and the value of pH that is related to the danger of seals according to Nakayama y Bucks (1991). A mathematical simulation model developed by Bralts (2010) was used to evaluate different filling situations in an irrigation subunit. The model consists in that the uniformity of the flow of the emitters is affected by the hydraulic, manufacturing and sealing factor.or the calculation of irrigation system management, the criterion of Bralts et al. (1981) was used, which is based on statistical uniformity, based on the uniformity coefficient and uniformity of system distribution, obtaining a management graph for irrigation.The development and validation of the methodology proposed to improve the management of micro-irrigation systems, were developed from the results reached in this experimental research work. It was validated during three years in conditions of production in UBPC “El Tezón” for the cultivation of guava. In the validation, five indicators were used: number of sealed emitters (NEO), percentage of seals (O), flow variation due to the sealing effect (ΔqO), crop yield (R) and net profit (Bn). The net benefit was determined from the following equations: Being:

Where Bn is the net benefit ($); CT the total cost ($); Bb the gross profit ($); R the crop yield (t / ha); Pv the sale price of the crop ($ t-1); As the system area (ha); CT the total costs ($); CP production costs ($); CF fixed costs ($); CO operating costs ($); Cfer fertilizer costs ($); Cpes the costs of pesticides ($); Cag water costs ($); CRM repair and maintenance costs ($), CLM costs of mechanized activities ($); CEE the costs of electric power ($); Csal salary costs ($); To amortization costs ($); Cs the total cost of the system, ($); Ka the amortization coefficient (adim.); T the lifetime of the installation (years), Cag the cost for water consumption ($); Va volume of water applied to the crop (m3) and Pa thewater price ($/m3).

To calculate the volume of water applied, the following equation was used:

Where Va is the volume of water applied, Ne number of emitters, Nl number of sides, qe flow of the emitter, Nr irrigation number, Tr watering time and O percentage of sealing.The transformations caused by the application of the proposed methodology with respect to the variant used by the production were statistically verified by the two-tailed hypothesis test, considered an alternative of general inequality. The hypothesis of nullity (H0) and the alternative (H1) were formulated so that if the calculated Student T-statistic (T) is greater than its critical value (Tc) for the level of significance (() of 0.05 it makes the decision to reject H0 and accept H1; showing that the compared means differ statistically:

Results and Discussion

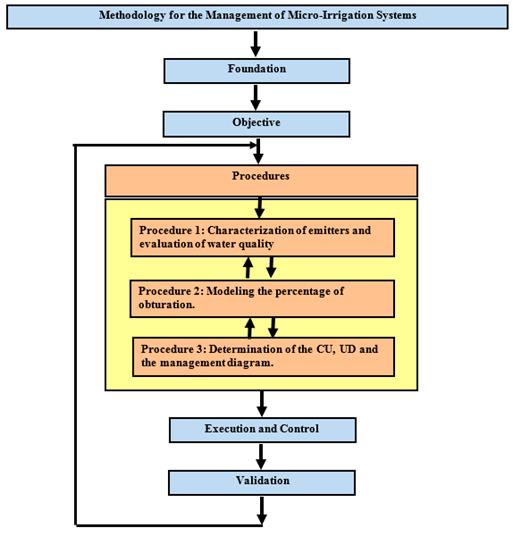

Structure of the Methodology: The essential procedures for the conformation of the proposed methodology are shown in Figure 2, which presents the following structure:

Fundamentation of the Methodology: The phenomenon of obturation is one of the aspects that has a notable impact on micro-irrigation systems that present efficiencies below those recommended. In the scientific literature, different methods are presented that contribute to improve the effects of this anomaly; but in general they appear as isolated procedures that are not always satisfactory for particular situations.

The proposed methodology is of great importance for micro-irrigation systems in Ciego de Ávila Province because it is one of the provinces in Cuba with the largest number of micro-irrigation systems and given the characteristics of the groundwater that these systems apply, they are potentially affected by the obturation of emitters, which justifies the need to develop a methodology to solve this situation satisfactorily

Objective of the Methodology: The objective of the methodology is to reduce the percentage of obturations in micro-irrigation systems to improve uniformity coefficient and the crop yield.

Procedures of the Methodology: The proposed methodology consists of three general procedures integrated among themselves in a systemic way, which constitutes their main element to achieve the improvement of the irrigation system based on the reduction of emitter’s obturation. These are:

Characterization of emitters and evaluation of the quality of irrigation water.

Modeling of the percentage of obturation.

Determination of the CU, UD and management diagram by Bralts criterion.

Each of the phases plays a fundamental role for the satisfactory fulfillment of the proposed objective. In this way the first procedure constitutes an important instrument for the definition of the hydraulic and mechanical characteristics of the emitters that will be used in the system and the determination of the quality of the water and its possible effect on the obturation. The second procedure is based on the use of a mathematical tool that simulates satisfactorily the magnitude in which the phenomenon of obturation could occur in the micro-irrigation system and the third procedure evaluates the behavior of the uniformity coefficient and the uniformity of distribution compared to different situations of system management from which the management diagram is constructed.

Execution and Control: The execution and control phase was directed from the point of view of management to compliance with the standards established for the system to operate with high efficiency, which has to be adequately controlled by all the people involved with this activity and is an important factor for achieving satisfactory results.

Validation of the Proposed Methodology: The results of the validation process are presented in Table 1 in which it was found that, the proposed methodology (M) produced better results compared to the treatment used in production (P), in terms of reduction the number of sealed emitters, the percentage of obturation and the deviation of the flow due to the sealing phenomenon. However, it achieved a significant increase in performance and net profit, which was demonstrated by statistical analysis from obtaining a value of the T-Student statistic calculated above the critical value for all the validation indicators evaluated.

All of the above confirmed that it can be used safely as an instrument for the management of micro-irrigation systems in the cultivation of guava in areas that have characteristics similar to those described in this research. It was possible to obtain an average yield increase of 3.79 t / ha with the application of the methodology.

TABLE 1 Validation indicators of the proposed methodology

| Indicators | Methodology | Production | T | TC |

|---|---|---|---|---|

| NEO | 34 | 75 | 41.77 | 4.30 |

| O (%) | 5.74 | 12.50 | 26.45 | 4.30 |

| ΔqO (%) | 5.50 | 14.00 | 187.36 | 4.30 |

| R (t/ha) | 60.13 | 56.34 | 5.76 | 4.30 |

| Bn ($) | 105092.59 | 87969.49 | 223.98 | 4.30 |

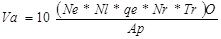

Diagram of irrigation system management and water distribution applied

The data obtained were adjusted to a normal distribution function, from this adjustment a relation was established between the applied sheet and the fraction of soil that is sufficiently irrigated. This result allowed to carry out the management process based on the experimental data, which influences the improvement of uniformity parameters, distribution and efficiency of system application. The relationship between the volumes of water applied to guava crop with Nann PC emitters, the efficiency of application, the deficit coefficient and the coefficient (f) that expresses the adjustment of the sheet applied to the normal distribution function is presented in Figure 1.

As the applied sheet increases, there is a gradual decrease in the deficit coefficient from a value of 0.24 which corresponds to a sheet of 0.80 milliliters to 0.029 for a sheet of 351 milliliters that then increases slightly. There is also an increase in application efficiency.

In the case of (f), a noticeable decrease occurs from a value of 1.66 for a sheet of 280 milliliters to 0.20 for a sheet of 373 milliliters. Finally, a stabilization was observed with a value of 1.2 for a sheet of 290 to 330 milliliters.

The management diagram is a very important tool for the irrigation system management process because the existing relationships between the deficit coefficient (Cd) and the volume of water required (Vr) are established considering its influence on the efficiency of application (AE). This information gives us the steps to follow during the management of the system, enabling water and energy savings with increases in crop yield.The diagram obtained from the experimental data allows conducting the irrigation considering the operating parameters of the system under production conditions as a basis.

Conclusions

The management graph obtained using Bralts criterion establishes the relationships between the deficit coefficient (Cd) and the volume of water required (Vr) considering its influence on the efficiency of application (AE) and indicates the steps to follow during the management of the micro-irrigation system, enabling water and energy savings with increases in the yield of guava crop.

With the validation of the proposed methodology in an irrigation subunit of “El Tezón” UBPC, a better management of the micro-irrigation system and increased the average yield of the guava crop by 3.79 t / ha were achieved.