INTRODUCTION

Probiotics are dietary additives, formed by live microorganisms that have a beneficial effect on the health of the host (FAO/WHO 2002). Generally, the application of these additives in animal production is related to the stabilization and protection of the gastrointestinal ecosystem, improvements in metabolic and digestive processes, as well as in the modulation of the immune system. These effects allow to increase the productive yields and, therefore, the availability and quality of milk, meat and eggs destined to the population (García et al. 2016). Currently, probiotics are an alternative to the use of antibiotics promoters of animal growth, since the use of the latter is limited or prohibited in many countries, due to the appearance of residual effects in food and problems of microbial resistance, associated with human and animal diseases (Blajman et al. 2015 and Gao et al. 2017).

In animal studies, microorganisms grown in the laboratory or commercial probiotics are used. The scaling from the laboratory to an industrial stage is not a trivial process, so for conceiving commercial probiotics, technologies must be designed to guarantee their development and efficiency. In this sense, the most important aspects are the adequate selection of the strain or strains, culture medium and fermentative conditions that allow obtaining a high level of viability during the process (FAO 2016). In general, in the available scientific literature, there is not abundant information about the production processes of probiotics or their economic studies, perhaps because they belong to transnational companies and, sometimes, associated with research groups that do not have the publishing of these aspects among their objectives.

In Cuba, at industrial scale, there is no production of probiotics for animals although several multidisciplinary groups study this subject and have microorganisms with these characteristics. Among them, there are strains of Lactobacillus (Brizuela et al. 2001, Rondón et al. 2012 and García et al. 2016), Bacillus (Milián et al. 2014) and yeasts (García et al. 2012b). In addition, it should be highlighted that high prices of probiotic products in the international market make them not affordable for their application in Cuban cattle rearing.

This study synthesizes the development of probiotics intended to animal production and the achievements of their research in Cuba

TECHNOLOGICAL PROCESS FOR OBTAINING PROBIOTICS

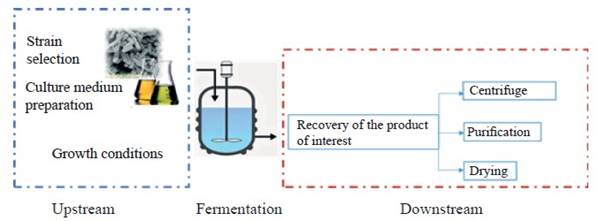

In the technological process for the development of probiotics, fermentations constitute the essential step and should be correctly defined for reaching high productive yields. Besides, two types of processes are included, which are known as upstream and downstream (figure 1). The former comprise the selection of the microorganism or microorganisms, their growth conditions and culture medium preparation. The second covers the recovery of the product of interest through different unit operations (Soccol et al. 2007). Figure 1 shows the fundamental elements of each stage.

UPSTREAM PROCESS. SELECTION OF PROBIOTIC STRAINS

The selection of microbial strain or strains is the first step towards the conception of a probiotic product. These should be Generally Recognized as Safe (GRAS) microorganisms, able to survive in the gastrointestinal tract and tolerate low pH and high concentrations of bile salts (Pintado et al. 2014). Other desirable characteristics are the ability of adherence of the probiotic strains to the intestinal epithelium for subsequent colonization (Endo and Gueimonde 2016), to be genetically stable microorganisms and to possess high growth rates. In addition, the chosen strain must maintain its viability and probiotic activity during the manufacturing, transport and storage processes (Dima et al. 2014 and Anadón et al. 2016). According to FAO/WHO (2002) reports, probiotics should have a minimum concentration of 106-107 cells mL-1 or g-1 of product to ensure its effectiveness. Likewise, other aspects should be considered, such as dose, frequency and application method, physiological state and age of the host.

The beneficial effects of probiotics do not depend on the strain origin. In fact, it is very difficult to confirm the source of a microorganism (FAO / WHO 2001). The specificity of the action depends on the strain or strains that are used in the products (Endo and Gueimonde 2016), so before its production, commercialization and application must be correctly identified, characterized in vitro and evaluated in vivo. In addition, the efficacy of probiotic preparations can be increased when more efficient strains are selected, mixtures of strains are used, genetic manipulations are carried out or when probiotics and synergistic components such as prebiotics are combined (Bomba et al. 2002). However, because there is no single methodology for the evaluation of probiotics, since different doses and application methods of these additives are used, inconsistent results may be obtained as there are strains with specific actions and others are multifunctional.

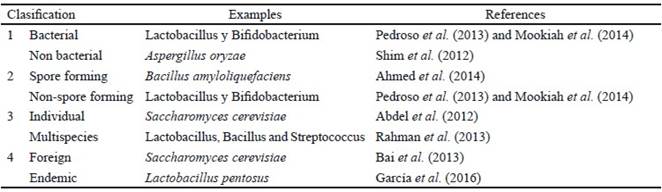

Taking into account the above characteristics, FAO (2016) classified probiotics into four large groups that are related and exemplified in table 1.

According to Anadón et al. (2016), the microorganisms most commonly used as probiotics are strains of Lactobacillus, Bifidobacterium, Bacillus, Enterococcus genera and yeasts. In the available scientific literature, most of the studies only take into account in vitro tests to demonstrate the probiotic potentials of strains. Some examples of these are those developed with Lactobacillus plantarum (Cebeci and Gürakan 2003), Lactobacillus acidophilus BS and Lactobacillus salivarius AWH (Orłowski and Bielecka 2006), Bacillus amyloliquefaciens B-1895 and Bacillus subtilis KATMIRA1933 (AlGburi et al. 2016). All these microorganisms grew at low pH and at high concentrations of bile salts, they were able to produce antimicrobial compounds and inhibit the growth of pathogenic species, which gives them potentialities as probiotics.

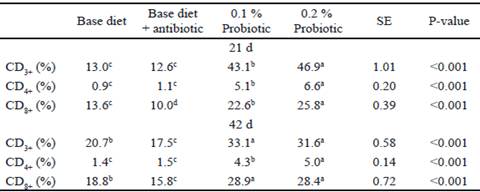

In animal production, a great variety of these microorganisms are obtained and evaluated in different species and animal category. In this sense, Bai et al. (2013) showed the stimulation of the immune system, without affecting productive yields, when they used a multispecies probiotic with Lactobacillus fermentum JS and Saccharomyces cerevisiae in concentrations of 107 cfu•g-1 and 106 cfu•g-1, respectively (table 2) in the diet of broilers.

Table 2 Effect of multispecies probiotic on subpopulations of intestinal intraepithelial lymphocytes in broilers at 21 and 42 d (Bai et al. 2013

a, b, c, d Values with different letters in the same line differ at P<0.05

CD3+ = T cells of poultry; CD4+ = auxiliary T lymphocytes of poultry; CD8+ =cytotoxic T lymphocytes of poultry

Afsharmanesh and Sadaghi (2014) reported improvements in the productive yields of this species, as well as an increase in the relation villus height/depth of the crypt in the duodenum, by providing a probiotic strain of Bacillus subtilis. Ahmed et al. (2014) reported the benefits of including a dose of 20 g of Bacillus amyloliquefaciens/kg of food in the diet by increasing immunoglobulin levels and decreasing Escherichia coli. The results of this last study are shown in the table 3.

Table 3 Effects of supplementation with probiotics of Bacillus amyloliquefaciens on serum concentration of immunoglobulins and caecal microbiota of broilers at 35 d (Ahmed et al. 2014)

During the last two decades, Cuba reached important results in obtaining and evaluating probiotics with beneficial effects in digestive physiology, health and productive performance of animals. Research roups from the Institute of Animal Science (ICA, initials in Spanish), the Cuban Institute of the Sugar Cane Derivatives (ICIDCA, initials in Spanish) and the University of Matanzas Camilo Cienfuegos (UMCC) are leaders in the field with the development of joint studies. Most of the studies isolated, identified and characterized strains from the gastrointestinal tract of broilers and other environments. The main results of these researches in different species and animal category are reported in table 4.

Other Cuban institutions also conducted research with a mixed culture of Lactobacillus acidophilus and Streptococcus termophilus in growing pigs (Rodríguez et al. 2009), mixed culture of lactic bacteria and yeasts (Marin et al. 2007 and Miranda et al. 2017), Lactobacillus isolated from fermented cabbage evaluated in white shrimp (Sánchez et al. 2013) and strains of the same genus, native to the gastrointestinal tract of neonatal calves (Sánchez et al. 2015). Similarly, the mixture of Lactobacillus acidophilus and Lactobacillus rhamnosus was used in young and growing sheep (López et al. 2014, 2015) and in the obtaining of marine actinomycetes with probiotic action in oysters and shrimps (García 2016).

Table 4 Main results of Cuban institutions, which are leaders in obtaining and evaluating probiotic additives for animal production

Despite the progress made in obtaining and evaluating probiotics in animals, there is little research to bring these additives to production level. Most of the studies focus on the search for new strains, and there is a gap in the development of the technological process to obtain probiotics at higher scales. This would be very important in animal feed from an economic and productive point of view.

CULTURE MEDIA FOR THE GROWTH OF PROBIOTIC STRAINS

The selection of suitable and economical culture media for industrial scale productions is an important aspect in obtaining probiotics. Generally, the culture media are selected according to the physiological characteristics of the strain of interest. However, Santos et al. (2016) consider that an appropriate culture medium should have peptides as nitrogen source, sugars as carbon source, yeast extract as growth factor, magnesium and manganese at optimum concentrations.

One of the most used selective media for the isolation, identification and growth of lactic acid bacteria is the De Man-Rogosa-Sharpe (MRS, pH 6.2 ± 0.2), designed by De Man et al. (1960). According to Santos et al. (2016), MRS can be more selective or differential depending on the modifications made to its composition. These may include the replacement of the carbon and nitrogen source, the decrease in pH or changes in incubation conditions (temperature, time and presence of oxygen). Before the formulation of MRS, Rogosa et al. (1951) described another means for Lactobacillus. It is considered that Rogosa medium is more selective than the MRS, due to its higher acidity (pH 5.4 ± 0.2) and the presence of high concentrations of sodium acetate (17 g / L), which is an inhibitor of other lactic acid bacteria (Streptococcus, Leuconostoc and Pediococcus) (Reuter 1985).

In general, cited media are widely used for probiotic strain growth at the lab in this stage. Most of researches are focused, according to the used strain, on optimization of media for the response surface methodology. However, the use of optimized media in the industry is not feasible due to the complexity of their composition and the high prices in the market. Every time an industrial culture medium is selected, technologists consider factors like costs, capacity for production of a great number of cells and fermentation methods (Santos et al. 2016). It is stated that the cost of culture medium constitutes around 30 % of the total cost of fermentation (Rodrigues et al. 2006).

Due to the previous reasons, it is necessary to increase the efforts in the search of more economic nutrient sources for the production of probiotic biomass at superior scales. The use of agro-industrial residues, such as substrata for microbial growth, has great importance because it deals with two fundamental problems. First, it provides less expensive nitrogen and carbon sources and, therefore, production costs decrease, and second, allow the use of wastes that should be treated before their removal, adds value to these last.

According to Santos et al. (2016), molasses, starch, rice and wheat bran, sugar cane or casava bagasse and lignocellulosic materials are among the most used agro-industrial by-products. There are also some animal origin wastes that can be used like cheese serum, whey permeate (Aguirre et al. 2009), whey protein hydrolyzed (Kim et al. 2006) and fish and shrimp wastes (Gao et al. 2006). It should be taken into account that the design of these new media may vary the probiotic properties of the selected strains (Dong et al. 2014), as the adherence ability at the intestinal epithelium (Deepika et al. 2012), the production of antimicrobial substances and modulation of immune system (Santos et al. 2016).

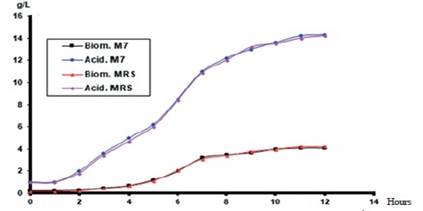

In Cuba, Brizuela (2003) used a modified MRS medium, called M7, for the growth of L. rhamnosus LB/103-1-5. This author substituted glucose for final molasses and nitrogen sources for basic hydrolyzed of Torula yeast. With this new medium, results were similar to control, with values of 4.01 g/L of biomass, 0.60 h-1 of maximum growth speed, 15.70 g/L of lactic acid, 34 % of biomass/substratum yield and 2.06 g/Lh-1 of process productivity.

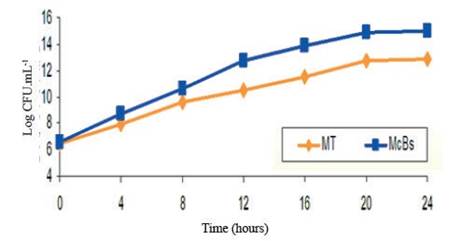

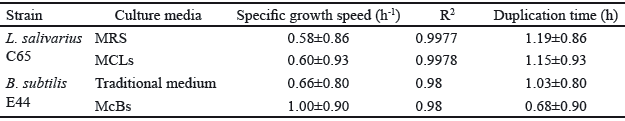

Likewise, Rondón (2009) and Milián (2009) also designed media with final molasses and an enzymatic hydrolyzed of S. cerevisiae yeast for the culture of L. salivarius C65 and B. subtilis E44, respectively. In each case, similar biomass values to those from the traditional medium were obtained (figures 2 and 3).

Figure 2 Growth kinetics of L. salivarius C65 strain in MRS cultivar media and the new designed culture medium (MCLs) (Rondón 2009)

Figure 3 Performance of E44 strain in a traditional medium (TM) and in the new designed medium (McBs) for Bacillus subtilis (Milián 2009)

From the previous results, authors determined specific growth speed and time of biomass duplication for each strain in the evaluated media. Table 5 shows those indicators. In all cases, values were found in the proper interval for the strains to be used as probiotic additives in animal production.

Miranda et al. (2015) used sweet cheese serum for the growth of L. acidophilus and S. thermophilus. These authors obtained microbial concentrations in the order of 108 cfu•mL-1 and, from the animal performance point of view, daily mean gains of 292 g/d, besides a reduction of diarrhea incidence up to 1.35 % in pigs treated with this product.

Table 5 Specific growth speed and duplication time of L. salivarius C65 (Rondón 2009) and B. subtilis E44 (Milián 2009) strains in traditional and new designed media (MCLs and McBs)

All these studies reached similar biomass concentrations to those obtained in traditional culture media, which were among the values recommended for the use of these additives. From an economical point of view, non-conventional culture media allow to reduce production costs of probiotics. However, it should be pointed out that they increase the amount of impurities, so it would generate higher costs if it is necessary to purify the product of interest. Then, it is important to perform studies benefit/ cost that justify the use of culture media based on agro-industrial residues.

CONDITIONS OF MICROBIAL GROWTH

It is considered that pH, temperature, agitation speed and dissolved oxygen are the indicators that have more incidence on microbial growth (Páez et al. 2013) and probiotic properties (Dong et al. 2014). Optimal values of these factors vary with the species and microbial strain, and should be correctly defined to obtain high yields in fermentation.

One of the main reasons of growth inhibition of probiotic microorganisms is low pH of culture medium. Therefore, controlling this indicator with a base or an acid, higher biomass yields can be obtained. Another solution is to co-culture a microorganism that counteracts the acid produced during metabolism (Muller et al. 2009).

With regard to temperature, most fermentations require between 30 °C and 37 °C to achieve optimal growth of probiotic microorganism. This variable is controlled by the supply of heat or cooling of the fermentation system through heat exchangers such as external jacket, internal and external coil (Doran 1995).

In aerobic bioprocesses, oxygen is an essential substrate that must be continuously supplied, due to its low solubility in culture media. Among the factors that affect the concentration of oxygen dissolved in the microbial suspension are the rate of oxygen transfer from the gaseous to liquid phase, the rate at which oxygen is transported to the cells (where it is consumed) and the rate of oxygen absorption by the microorganism for growth, maintenance and production (García and Gómez 2009).

Regarding the subject that is approached, there is not abundant scientific information available from the studies carried out in Cuba. Brizuela (2003) studied, in fermenters of 5 L of total capacity, temperature influence, agitation and pH on the growth of L. rhamnosus LB/103-1-5. The author showed that to obtain a concentration of 1010-1011 cfu • mL-1, it was necessary to work at a temperature of 39 ± 2 °C, pH of 6.3 ± 0.3 and 300 rpm of agitation. These results allowed us to design a technological procedure to obtain a probiotic preparation with characteristics comparable to other similar products, reported in the scientific literature.

In summary, it is necessary to emphasize the importance of correctly defining the growth conditions for the new probiotic microorganisms that are obtained, since these will be different for each strain and will be the basis for future scaling studies.

FERMENTATION PROCESS

Fermentation is the most complex stage in the production of probiotics or any microbial additive. This stage consists on the use of the components of the culture medium to produce microbial cells in high concentration, extracellular products (for example, lactic acid), enzymes, amino acids, vitamins and other pharmaceutical compounds (FAO 2016). In addition, it can be performed in the presence or absence of oxygen, called aerobic or anaerobic fermentation, respectively (Bamforth 2005).

There are different fermentation methods for the production of probiotics at industrial level, including continuous batch and fed-batch fermentation (Alfonso et al. 2011). Batch processes are the most used because they are the cheapest (Muller et al. 2009). However, continuous and fed-batch cultures may be useful for improving yield of industrial fermentations (Doleyres et al. 2004).

Batch fermentations consist of mixing the substrate and the inoculum in a bioreactor and not adding or removing any component during growth. Once the desired cell concentration or the product of interest is reached, the fermentation is stopped and the process is repeated (Santos et al. 2016). In the case of continuous fermentation, the fresh culture medium is continuously added to the bioreactor, while the microbial cells and the metabolites produced are removed simultaneously at an identical rate (Lamboley et al. 1997). In this way, the continuous production of probiotic is maintained without inhibiting microbial growth. However, there is a greater risk of contamination when this technology is applied on an industrial scale (Lacroix and Yildirim 2007).

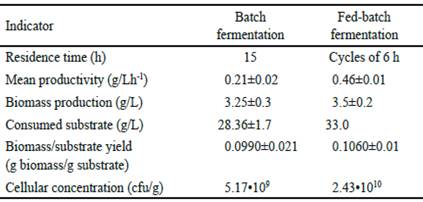

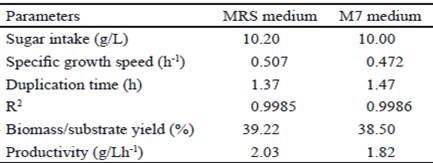

In the case of fed-batch fermentations limiting nutrients are added during growth and no component is removed until the end of the process (Muller et al. 2009 and Radwan et al. 2011). This technique increases microbial concentrations, since it allows controlling the metabolism of the strain (Thiry and Cingolani 2002). In addition, it can be used to induce a stress response to bacteria and protect them from later stages, such as downstream processes (Muller et al. 2009). Aguirre et al. (2009) showed that this process offered better yields than fed-batch fermentation to obtain probiotic biomass of Lactobacillus casei in goat serum permeate at 37 °C and pH 5.5 (table 6).

Other methods for obtaining probiotic biomass are fermentations in membranes and immobilized cells. According to Santos et al. (2016), in the former, cells are retained with an ultrafiltration or membrane microfiltration system and fresh culture medium is continuously supplied. The smaller molecules are spread through the pores of the membrane, cells are concentrated and inhibitory metabolic products are eliminated in the permeate. In these systems, there are different pressures, such as low concentration of nutrients, oxygen, mechanical and osmotic pressure that could affect the viability of the most sensitive microorganisms. Immobilized cell technology consists of microbial growth on solid porous supports during incubation in rich media. The formation of a region of high cellular density is obtained with this technology.

An important aspect for the conception of a commercial probiotic additive is the scaling process. At present, it is a challenge to bring laboratory-level results to an industrial scale. This is because, at higher scales, most fermentation processes provide lower yields than those obtained in the laboratory (Bylund et al. 2000). In general, when the scale changes, multiple difficulties appear with the design of the equipment, mass and energy transfer phenomena, pH control, temperature, aeration, agitation and sterilization of the medium. There are also important incidences, in the biological factors associated with the development of the microorganism, its probability of mutation and contamination (Helene 2004).

In the consulted scientific literature, there was not abundant information about the technologies and scaling of probiotics in Cuba. Brizuela (2003) studied the effect of scale change on the physiological, kinetic and productive parameters of the Lactobacillus rhamnosus strain LB/103-1-5 in a 20 L fermenter. Figure 4 shows production curves of biomass and acid that were obtained at this scale for the MRS medium and a culture medium designed from more economic sources.

Table 7 shows values of different kinetic and productive parameters reached in these conditions.

Based on the previous results, the author pointed out that for this volume of production, there were no significant differences in the productive parameters of the microorganism. These researches demonstrate the possibilities of obtaining probiotics at national level and, with it, diminishing costs by concepts of import to the country of this type of product that has beneficial effects on animal production.

Table 7 Kinetic and productive parameters of LB/103-1-5 strain in MRS and M7 media in a fermenter of 20 L (Brizuela 2003)

The scaling of the fermentative process is long and expensive and must be reduced, in order to shorten the time between the conception of a product and its introduction into the market. In the definition of the limits between one scale and another, there is a great diversity of criteria. The best one is selected according to the objectives and results that are pursued with each of these scales. Usually, only the laboratory, pilot plant and industrial plant stages are taken into account. In summary, the success of the scaling will be given by obtaining results that show that there is no difference between small and large scale.

DOWNSTREAM PROCESS

Downstream processes, as mentioned before, cover the recovery of the product obtained from fermentation through different unit operations. In this case, if the interest is only biomass, it can be separated by centrifugation or filtration. Then, if it is required, the product can be dried to facilitate transportation and storage.

Generally, probiotics are dried by lyophilization because it is a less aggressive method, which allows the conservation of live bacteria (Foerst 2016). Spray drying, vacuum drying and fluidized bed drying are also used (Broeckx et al. 2016). These latest techniques are characterized by lower costs of investment, energy, shorter times and the possibility of continuous processing (Foerst 2016). All these operations can cause stress to the probiotic strains and with it, the loss of their viability (Saarela and Mattila 2007). Therefore, it is necessary to check this indicator, after using any of the mentioned methods. Studies with Probicid product, for example, showed that spray drying was not efficient, since it affected 99 % of cell viability. Thus, the authors proposed formulations of the probiotic preparation with chemical repressors of water activity (Febles et al. 2016).

For the above reasons, the maintenance of cell stability and viability throughout the downstream process is highly important for a successful production of probiotics. Recent studies show that microencapsulation allows the protection of probiotic cells under conditions of stress, storage and during passage through the gastrointestinal tract of animals (Eckert et al. 2017 and Hai et al. 2017).

FINAL CONSIDERATIONS

The development of probiotics for animal production is essential, due to the benefits offered by these additives. For this reason, it is vital to define the technological process, taking into account that the conditions of growth and operation of the fermentations are specific to the species and strain used.

Cuba has important contributions to knowledge in obtaining probiotic strains, although research aimed at the development of these additives, which are economically feasible to achieve their application in livestock systems, must be continued. It is also necessary to increase work relationships between national and international institutions to strengthen research and contribute to the scientific and technical progress in this area. Likewise, it would be interesting to establish national policies that prioritize and guarantee the obtaining, production and application of probiotics destined for animal production.

texto en

texto en