INTRODUCTION

Life and career (Anonymous, 1887; Schützenberger, 1886; Anonymous, 2022)

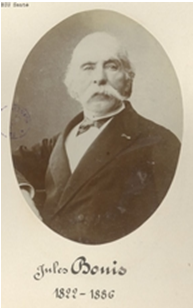

Jules Bouis was born on April 2, 1822, in Perpignan (Pyrénées-Orientales), France, the son of Mathieu Dominique Bois (1797-1866) a pharmacist, and Marguerite Raymonde Vilar (1798-1884). After finishing his basic education his father sent him to study pharmacy and mathematics at the University of Montpellier with the hope that he would continue the family business. After completing his studies, and also obtaining his diploma of bachelier ès sciences mathématiques, Bouis returned to Perpignan to help his father, who understood the aspirations of his son and sent him to Paris, carrying a letter to his friend François Arago (1785-1853), another son of Perpignan. Arago presented Bouis to Jean-Baptiste André Dumas (1800-1884) who hired him to study and work in his laboratory. In 1846, after receiving his diploma of licencié ès sciences physiques, he moved to the Conservatoire des Arts et Métiers as préparateur of the course in general chemistry given by Eugène Melchior Péligot (1811-1890), a position he kept until 1857. In 1849 he was appointed professor of chemistry and physics at the Collège Chaptal (today Lycée Chaptal), which trained pupils for careers in commerce or manufacturing. In 1853 he was appointed préparateur to the chemistry course given at the École Centrale des Arts et Manufactures. In 1855 he received his doctoral degree from the Faculty of Sciences of Paris after successfully defending a thesis about castor oil and caprylic alcohol (Bouis, 1855c). In 1859 he won the aggregate competition (the door to an academic career) of the École Supérieure de Pharmacie with a thesis regarding poisoning by gases (Bouis, 1858a), and was appointed adjunct professor at the École. This position was followed by a rapid series of academic and professional appointments: head of chemical works at the Académie de Médicine (1859), chemical analyst at the French Mint (1864), professor of chemical analysis at the École Centrale des Arts et Manufactures (1864), chair of toxicology at the École de Supérieure Pharmacie (1865), member of the Académie de Médicine (section physics and chemistry) (1878), etc. (Anonymous, 1887; Schützenberger, 1886; Anonymous, 2020).

In 1853 Bouis married Sophie de Milly (1833-1904), the daughter of Louis Adolphe Lezin de Milly (1799-1876), a physician and manufacturer of candles. Five children were born of this union: Louise Marie Clémentine, Adolphine Amélie, Raymond Lucien, Henri André, and Georges Louis.

Bouis served in many scientific and public positions, among them, corresponding member of the Société Agricole, Scientifique et Litteraire des Pyrénées-Orientales (1876), member of the Société de Encouragement and of the Société de Pharmacie, chevalier of the Ordre de l'Immaculée Conception de Vila Viçosa (Portugal, 1856), chevalier of the Légion d'Honneur (1865), collaborated with Charles Adolphe Würtz (1817-1884) in the publishing of the Dictionnaire de Chimie Pure et Appliquée (1869), etc. (Anonymous, 1887; Schützenberger, 1886; Anonymous, 2020).

Jules Bouis passed away in Paris, on October 21, 1886.

Scientific contribution

Bouis wrote about 40 papers and books (i.e., Bouis, 1871a; Reynoso & Bouis, 1855; Briand, Chaudé & Bouis, 1874) on the subjects of inorganic, organic, and biochemistry, physiology, etc. As customary for candidates to the Académie de Médicine, he published a booklet describing the results of his scientific research (Bouis, 1858b). In addition to the subjects described below, he studied the presence of ammonia in argillaceous minerals (Bouis, 1827a), and the composition of renal and intestinal calculi (Bouis, 1827b); he described the new deposit of magnesium sulfate located in Fitou (Bouis, 1843); he studied the influence of temperature on electrolysis (Bouis, 1849); the properties of thermal waters (Bouis, 1841, 1853, 1856b, 1858c, 1863), poisoning with HCl, (Bouis, 1871b), and the composition and properties of the oil of Jatropha podagrica (oil of Médicinier) (Bouis, 1854c); etc.

In what follows attention must be paid to the fact that Bouis wrote his chemical formulas using the old values of atomic masses, for example, C = 6, N = 14, Cl = 35.5, HO = water, N2H8Cl2 = ammonium chloride, and hydrogen is monatomic.

Castor oil, its components and derivatives

This topic was the subject of several Bouis's publications and of his main doctoral thesis (Bouis, 1851a, 1854a b, 1855a c d, 1856a). The first part of his thesis was a review of the information available about castor oil. He mentioned that the properties of castor oil were quite different from those of the other known vegetable oil. In spite of the many scientists that had investigated castor oil, the available knowledge was far from been satisfactory. The castor oil plant (Palma Christi, Ricinus communis) grew in large areas of Africa, India, and parts of America. Its seeds were the highest yielding oil seeds (60 to 64%) among the other oil producing plants. The oil was extracted by simple treatment with boiling water and was frequently used as a purgative or for illumination purposes. Bouis added that this action did not seem to be the same among all individuals; the Chinese boiled it with aluminum sulfate and sugar and used the product as a seasoning (Bouis, 1855c).

Bouis wrote that castor oil was greasy transparent oil, yellow or greenish, with dull odor and sweet taste, which then became slightly acrid. It thickened in contact with air and then dried. It did not solidify even when cooled down to -15 oC with a refrigerating mixture. Its relative density was 0.960 (19 oC) and some researchers claimed that it deviated the plane of polarized light. It dissolved totally in absolute ethanol and partially in aqueous alcohol (all other known oils were insoluble in alcohol). Upon distillation it yielded a variety or products that did not include sebacic acid (decanedioic acid, HOOC(CH2)8COOH). According to several reports, it contained, by weight, 74.00 to 74.58% of carbon, 10.29 to 11.48% hydrogen, and 13.94 to 15.71% oxygen. When heated it decomposed into gas, volatile acids, hydrocarbons, acrolein, and a volatile oil. After a certain time, it swelled and became thicker; the flask filled with a spongy yellow material, without taste and odor, sticking to the fingers, not affected by air, insoluble in alcohol and ether, and very fragile. Elemental analysis indicated that it contained, by weight, 73.2% carbon, 10.9% hydrogen, and 15.9% oxygen, corresponding to the formula C36H32O6 (Bouis, 1855c).

According to Bouis, Antoine Alexandre Brutus Bussy (1794-1882) and Louis René Le Canu (1800-1871) had been the first to study the action of heat upon castor oil and its distillation (Bussy and Le Canu, 1827). The initial fraction passed without release of gases and was then followed by a mixture of volatile and fixed oils, acetic acid, and fixed fatty acids. The volatile oil was colorless and very transparent; had relative density 0.815, began boiling at about 100 oC and continue to do so up to 150 oC. This result indicated that it contained at least two different substances. The fatty material accompanying this oil was found to be a mixture of two new fatty acids, one solid and the other liquid, which Bussy and Le Canu named ricinic (today, ricinoleic acid), and elaiodic acids, respectively. Ricinic acid was a white pearly and extremely acrid solid, melting at 22 oC, completely insoluble in water, very soluble in alcohol and ether, and volatilizing without alteration Elemental analysis indicated that it contained, by weight, 73.56% carbon, 9.86% hydrogen, and 16.58% oxygen. Elaiodic acid was a yellow acrid liquid that remained so even at temperatures below 0 oC (Bussy and Le Canu, 1827). Bussy analyzed the volatile oil and found that it was œnanthaldehyde, C14H14O2 (œnanthol) (Bussy, 1845).

Bouis added that the pharmacist Jean-Joseph-Étienne Poutet (1779-1828) had discovered that mercurous nitrate transformed non-drying oils into a solid material and that this reaction could be used as a tool for recognizing falsified oils (Poutet, 1819). Félix Henri Boudet (1806-1878) had afterwards found that this effect was due actually to hyponitrous acid and proposed using this acid dissolved in nitric acid for identification purposes. Boudet named palmine the product obtained with castor oil, which turned out to be the only drying oil that gave a solid product (Boudet, 1832). Bouis reported that in spite of many trials he had failed to produce palmine by the method proposed by Boudet but that he succeeded by bubbling hyponitrous acid through castor oil. Purified palmine was a white material melting at about 45 oC that alkali transformed into palmitic acid; the latter should not be confused with the palmitic acid obtained from palm oil. For this reason, Bouis suggested naming it ricinelaidic acid, and, consequently, palmine should be named ricinelaidine. Concentrated KOH transformed ricinelaidine into a mixture of sebacic acid, caprylic alcohol, and other unidentified acids, Ricinelaidic acid was a white solid, crystallizing as pearly needles, melting at 50 oC, which could be prepared by saponifying palmine with KOH and decomposing the resulting soap with HCl. Elemental analysis indicated that its composition corresponded to the formula C36H34O6, isomer with ricinoleic acid (Bouis, 1855c).

Bouis prepared œnanthol and described it as a colorless liquid, of relative density 0.827 (17 oC), having a strong smell and acrid burning taste, and acting strongly upon the bladder. It boiled between 155o and 156 oC; it reduced silver nitrate and was unstable in contact with air. Distilled in the presence of phosphorous pentoxide it yielded the hydrocarbon œnanthylene, C14H14, CH3(CH2)4CH=CH2, boiling at about 50 oC.

Bouis described the result of the reaction of castor oil with nitric acid, the chromic mixture, calcium chloride; diluted and concentrated alkalis, and ammonia (Bouis, 1855c). Diluted alkalis separated a soap, which HCl decomposed into a mixture of margaric, ricinic, and elaidic acids. The reaction with ammonia was particularly interesting. In 1843 Pierre François Guillaume Boullay (1777-1869) reported that the reaction between ammonia and a fatty material was totally different from that with the fixed alkalis (KOH and NaOH) because amides of the fatty acids were formed (Boullay, 1843). He saponified olive oil by means of a current of ammonia gas, by mixing it with an alcoholic solution of ammonia, or by leaving it in contact for a long time with an aqueous solution of ammonia. The resulting soap was insoluble in cold water, with boiling water it formed a milky suspension (like a true solution of soap) and was completely soluble in alcohol. On cooling, the alcoholic solution deposited a white transparent crystalline silky substance, perfectly neutral. Elemental analysis of this substance indicated that it contained, by weight, 13.5% hydrogen, 75.63% carbon, 5.33% nitrogen, and 5.99% oxygen that corresponded to the formula C34H33O2(NH2) that is margaramide (Boullay, 1843).

Boullay proceeded to analyze the substance by melting and drying it in a sand bath, followed by oxidation with cupric oxide. His results indicated that it contained, by weight, 13.5% hydrogen, 75.63% carbon, 5.33% nitrogen, and 5.99% oxygen, a composition that corresponded very well with the formula, in equivalents, C34H33O2(NH2), representing margaramide. Similar results were obtained with other vegetable oils (Boullay, 1843). Bouis found that the reaction of castor oil with an alcoholic or an aqueous solution of ammonia also produced a solid representing the amide of ricinoleic acid, which he named ricinolamide (Bouis, 1851a, 1855c). In the beginning, the reaction mixture appeared formed by two liquid phases that slowly fused into one, while a white solid began to form. The alcoholic solution was then evaporated over a water bath and the separated solid expressed or purified by recrystallization from alcohol. Ricinolamide was a white solid, melting at 66 oC, insoluble in water and soluble in alcohol and ether, and burning with a very sooty flame. Concentrated sulfuric acid decomposed it into a strong red liquid. Treatment with cold acids separated ricinoleic acid and the ammonia salt of the corresponding acid. It did not react with cold KOH but with concentrated KOH it disengaged ammonia leaving behind a residue of potassium ricinoleate. Its formula was C36H35NO4, corresponding to ammonium ricinoleate minus the elements of water. Bouis reported the preparation and properties of silver and barium ricinoleate. During the heating of ricinolamide with concentrated KOH or NaOH, the material begun to swell and distill abundant hydrogen and a volatile oil, lighter than water and having a particular smell, which eventually was identified as caprylic alcohol. HCl decomposed the residual soap into sebacic acid mixed with other acids. Sebacic acid was separated by washing with boiling water; elemental analysis indicated that it contained, by weight 60.52% carbon, 8.97% hydrogen, and 30.51% oxygen, corresponding to the formula C20H18O8. These results indicated that under the action of very concentrated KOH, ricinoleic acid decomposed into caprylic alcohol, sebacic acid and hydrogen, according to (Bouis, 1851a, 1855c):

Sebacic acid was a white crystalline solid, melting at 127 oC. According to Bouis, wrote sebacic acid was produced industrially by distilling oleic acid or certain fats containing olein. This procedure had two inconveniences; it released a highly repugnant odor and had a very low yield. For these reason Bouis tested successfully the possibility of producing sebacic acid by the direct action of concentrated KOH on castor oil. In this new procedure the obnoxious odor was replaced by the light aromatic odor of the volatile oil (caprylic alcohol) produced. Bouis described this oil as a transparent and colorless liquid, having an agreeable aromatic odor, staining paper as essential oils, insoluble in water, soluble in alcohol, ether, methanol, and acetic acid, optically inactive, and burning with a white flame. It boiled at 180 oC (760 mmHg) without decomposing and had relative density 0.823 (17 oC). It dissolved calcium chloride forming beautiful transparent crystals decomposable by heat or water into calcium chloride and volatile oil. It was very good solvent for fatty material, resins, sulfur, phosphorus, and iodine. It was not affected by air and did not react with silver nitrate. It reacted with acetic acid and HCl yielding ethers smelling like fruits. Hot sulfuric acid converted it into a hydrocarbon, isomeric with ethylene and amylene. This was a very light hydrocarbon, lighter than water, boiling at 125 oC without decomposing. These and other properties demonstrated clearly that this volatile oil was an alcohol (Bouis, 1851a, 1855c).

The following section of the doctoral thesis provided a detailed description of the preparation of caprylic alcohol, its properties, and derivatives, and included information reported in a previous paper (Bouis, 1854c, 1855c). Bouis repeated the main properties of caprylic acid and added that it reacted with cold sulfuric acid to yield sulfocaprylic acid that produced crystallizable salts with barium, calcium, and potassium. Hot sulfuric acid converted it into a hydrocarbon, isomeric with alkenes. It reacted with hydrogen chloride, iodide, and bromide to yield the pertinent halogenated alkyls. Caprylic could not be preserved over calcium chloride because it reacted with this salt, producing very deliquescent crystalline prisms. According to Bouis, caprylic alcohol was one of the best solvents for fatty materials and resins, suggesting that it could be used for preparing varnishes. It could also be used for illumination purposes, replacing turpentine, or coal oil because it did not produce a disagreeable odor, burned with a beautiful flame, and did not catch fire when approached by a candle. Bouis added that the reaction of castor oil with KOH yielded 25% of its weight as sebacic acid, 25% of its volume as colorless alcohol, and the rest was a mixture of fatty acids, a liquid looking like oleic acid, and a solid having the composition of cetylic alcohol (Bouis, 1854a, 1855c).

Afterwards, Bouis described the preparation and properties of several derivatives of caprylic alcohol, among them, chlorocaprylal, caprylene, the derivatives formed with bromine, nitric acid, sulfuric acid (potassium and barium sulfocaprylate), phosphoric acid, capryl chloride, bromide, iodide, acetate, and sulfide, capryl caprylate, mixed capryl esters, capryl amide, etc. (Bouis, 1854a, 1855c). Thus, caprylene, C18H16, was a colorless refractive fluid with a rather strong odor, insoluble in water, soluble in alcohol and ether, and burning with a very luminous flame. Its relative density was 0.723 (17 °C) and boiled at 125 oC (760 mmHg) without decomposition. It was easily prepared by distilling caprylic alcohol mixed with sulfuric acid or with fused chloride of zinc. Bouis found that distilling pure caprylic alcohol with fused zinc chloride resulted in the complete conversion of the alcohol into caprylene. According to the duration of the contact, the reaction with ordinary sulfuric acid furnished sulfocaprylic acid, 2SO3,C16H17O,HO, or a mixture of caprylene and sulfuric ether, or a hydrocarbon isomeric with caprylene, but possessing very different properties. Its relative density was 0.814; it began boiling at about 250 °C and at much higher temperature its odor became unbearable, resembling that of perspiration. Sulfocaprylic acid was a colorless syrupy fluid, very soluble in water and alcohol; upon heating heated it turned black and decomposed. This acid was prepared by decomposing barium sulfocaprylate with dilute sulfuric acid or lead sulfocaprylate with hydrogen sulfide, followed by evaporation under vacuum. The barium salt had a pearly white color, was fatty, very soluble in water and alcohol, and decomposed at about 100 °C. Potassium sulfocaprylate was white and pearly and not affected by air. It was very soluble in water and alcohol and could be prepared by double decomposition by means of the barium salt, or directly by saturating sulfocaprylic acid with potassium carbonate (Bouis, 1854a, 1855c).

Capryloacetic ether, C18H17O,C4H3O3, was a liquid of a very agreeable odor, insoluble in water, and boiling about 190 °C. It could be readily obtained by reacting caprylic alcohol with acetic acid under with a current of HCl, or better still, by reacting sodium acetate with sulfuric acid. Capryl chloride, C18H17Cl, was a liquid insoluble in water, slightly soluble in alcohol, smelling like orange, burning with a smoky green flame, and boiling at about 175 °C. It was prepared directly by means of HCl or by phosphorus pentachloride. This reaction was extremely strong and could result in the inflammation of the alcohol; for this reason, the chlorine should be added very slowly and under refrigeration. The chlorine atom could be removed by means of sodium producing dicapryl, (C16H17)2, or caprylene, C18H16, depending on if the reaction was carried under cold or hot conditions. Further reaction with chlorine resulted in the formation of chlorocaprylal, C16H11O2Cl5. Capryl iodide, C18H17I, and capryl bromide, C18H17Br, were very similar to capryl chloride. The reaction with bromine was very strong and should be carried slowly. Potassium sulfocaprylate was a white pearly salt, soluble in water and alcohol; it burned completely, leaving a residue of potassium sulfate. Heated with an aqueous KOH transformed it into potassium sulfate and caprylic alcohol. Barium sulfocaprylate was very soluble in water and alcohol and very difficult to dry. Above 100 oC it lost water constantly. By calcination it left a residue of barium sulfate (Bouis, 1854c, 1855c).

Bouis reported that that phosphoric acid reacted with caprylic alcohol to form phosphocaprylic acid, which formed soluble salts with lead, calcium, and barium. Capryl sulfide, (C16H17S)2, was a light liquid of a disagreeable odor, very soluble in alcohol and unstable to heat. It was easily prepared by heating capryl iodide with an alcoholic solution of hydrogen sulfide. The reaction was very fast, the resulting capryl sulfide separated as an oily liquid, insoluble in the alcohol loaded with sodium sulfide and iodide. Capryl caprylate was prepared by the reaction of the sodium alkoxide with capryl chloride. It was a very volatile liquid that began boiling at 50 oC. The mixed esters were prepared by a similar procedure: heating the desired sodium alkoxide with capryl iodide. Capryl amine, C16H17(NH2), was easily prepared by reacting an alcoholic solution of capryl iodide with a stream of ammonia. The amine was a colorless liquid, lighter than water, insoluble in water and soluble in alcohol and ether, extremely caustic, and boiling at about 175 oC. In contact with HCl it generated thick white vapors (Bouis, 1854a, 1855c).

Bouis also described the reaction of alkaline metals with capryl chloride, bromide, and iodide (Bouis, 1854b, 1855c). At room temperature the reaction with capryl chloride yielded a liquid having composition C16H17, which indicated that capryl chloride had lost its chlorine to yield a substance composed of (C16H17)2, or a mixture of the hydrocarbon C16H18 and caprylene C16H16. Under the influence of heat the reaction was completely different: initially the metal assumed a violet color and swelled substantially, and then, as the temperature started to increase, the color of the metal disappeared, and hydrogen began to be released. The resulting liquid was found to be caprylene. Bouis found that the violet substance was stable in caprylene or in naphtha but was decomposed by water, alcohol, and other oxygenated reagents. Pressed between sheets of paper, and in contact with air, it lost it color and became white while converting into sodium chloride and NaOH. Calcined it released hydrogen and left a carbon residue containing highly divided sodium. According to Bouis this substance might be envisioned as a chloride combined with the hydrocarbon C16H16, where one atom of hydrogen had been replaced by its metallic equivalent, (C16H15Na)NaCl. The corresponding bromine and iodine compounds were (C16H15Na)NaBr and (C16H15Na)NaI (Bouis, 1854b, 1855c). An additional paper described the formation of caprylic aldehyde. This substance was a colorless liquid having relative density 0.818 (19 oC) and boiling at 171 oC (760 mmHg). It smelled strongly like banana and had a caustic taste. It was insoluble in water, soluble in alcohol, ether, and fatty oils, and burned without smoking. It reduced silver nitrate yielding a beautiful metallic mirror and seemed not to be oxidized by air and cold oxygen, but hot oxygen converted it into caprylic acid. It combined with sodium bisulfite without change in temperature; the resulting compound was insoluble in an aqueous solution of the bisulfite (Bouis, 1855d, 1856a).

ŒNANTHYL ALCOHOL

In a related paper, Bouis and H. Carlet reported the preparation and properties of œnanthyl alcohol (Bouis and Carlet, 1862). Œnanthal and caprylic aldehyde were completely different compounds and the preparation of the respective alcohols would allow their better comparison. A solution of œnanthal in glacial acetic acid was mixed with zinc and the whole heated under a slight pressure to facilitate the reduction. The alcohol produced reacted with the acetic acid to produce the pertinent ester, œnanthyl acetate. The product of the reaction was washed with water and the excess aldehyde eliminated with sodium bisulfite. The resulting oily material was separated from the water phase and purified by distillation. The ester was a liquid boiling at about 180 oC and smelling like fruit. Treated with aqueous KOH it decomposed into potassium acetate and œnanthyl alcohol, C14H16O2, a colorless liquid, insoluble in water and boiling at 180 oC without decomposition. Treatment with sulfuric acid and neutralization with potassium, barium, or calcium carbonate yielded the pertinent sulfosalt. Distillation over fused zinc chloride yielded a very light liquid, insoluble in water and boiling above 100 oC. It was œnanthylene, of formula C14H14 (Bouis and Carlet, 1862).

Fusion and solidification of fats

Bouis wrote that his long relation to the fat industry (Louis de Mill, his father-in-law, owned a candle-making factory) had led him to study the determination of the fusion and solidification phenomena of the different raw materials (Bouis, 1855b, 1869). Several techniques were available for this purpose, for example, heating the fat while holding a thermometer inserted into the sample, heating small ampoules filled with the fat and noting the moment the fat liquefied, and heating in water a small sample hanging from a wire. Bouis decided in an alternative procedure, based on the heat of fusion. He covered the bulb of the thermometer with a small layer of fat and put it into a space heated to a temperature several degrees above the melting point of the sample. This resulted in the material becoming liquid and cooling the reservoir, while the temperature remained constant for a short time, signaling the fusion point (Bouis, 1855b, 1869).

Bouis wrote that in principle, all the above procedures seemed appropriate, but it was not so: They were difficult to carry on due to the poor thermal conductivity of the fats. This originated because part of the solid material remained as such in the mass of the liquid causing the liquid to achieve a higher temperature. This led Bouis to design a more accurate procedure. He used very thin tubes, 4 to 5 mm in diameter and 12 to 15 cm long; one of their extremes was elongated by about 2 cm to form a very slim tube, which he filled with fat. The tubes were now immersed in water heated to a few degrees below the melting point of the fat. The water was now heated very slowly, under constant agitation. At the fusion point the liquid was seen to rise in the tube. According to Bouis, the literature seldom reported the true fusion point; the operator let the liquid solidify and assumed the fusion temperature was the same as the solidification one. This was true enough for acid substances but with neutral fats the difference between the two temperatures was usually very large. The solidification point was usually selected as the preferred one because it was easier to measure with a thermometer submerged in the sample. During solidification the temperature remained constant. The problem with neutral substances was particularly serious, especially when working with mixtures of variable composition (Bouis, 1855b, 1869).

Bouis recommended solving the problem by using a cooling procedure. The sample was melted in a tube containing a very sensitive thermometer (1/10 of a degree). The tube was place inside an evacuated flask, protected from abrupt changes in temperature and submerged in a large water bath. Temperature measurements were taken at fixed periods of time. Bouis provided a table describing the change in temperature with time of a sample of commercial stearic acid, when the evacuated flask was submerged in ice, or was let to cool slowly inside a water bath. In both cases he obtained the same result (54 oC) for the solidification temperature. He found the same result when using other fatty materials (spermaceti, sebacic acid, tallow, stearin, and cetyl alcohol), as illustrated by the pertinent tables. Bois recommended drawing the curve temperature against time, for a better visualization of the solidification point (Bouis, 1855b, 1869).

Bouis remarked that heat and its regime were the most important factors in obtaining the appropriate answer. Patrick Duffy submitted a given fat sample to repeated cycle solidification/melting cycles and found that it returned a very similar solidification temperature but usually an increasing fusion temperature. He attributed the changes to isomeric changes taking place in the material (Duffy, 1853). Bouis believed it was caused by the poor thermal conductivity of the fat, which was also very different for the solid and liquid phases of the substance and could lead to a delay in the solidification point or to an advance in the fusion point. He justified this argument by the fact that the volume of a fat suffered a notable contraction on passing from the liquid to the solid phase (fats are normal substances, their solid sinks in its liquid phase). This contraction varied with the composition of a mixed fact and could be used to detect possible falsifications. In addition, fats absorbed a larger amount of heat as they were heated (specific heat varying with temperature). Bouis quoted the results of Johann Gottlieb (1815-1875) about the melting point of varying mixtures of stearic acid with margaric acid from; a mixture of 30 parts of stearic acid with 10 of margaric acid melted at 65.60 oC while a mixture of 10 parts of stearic acid with 30 of margaric acid melted at 56.00 oC (Gottlieb, 1846). Bouis also mentioned that behaved differently, all have at least one fixed point (today, eutectic point) that occurred at a temperature below that of the lowest melting compound, independent of the starting composition (Bouis, 1855b, 1869).

Action of chlorine on mercury chloride

Joseph-Louis Gay-Lussac (1778-1850) described the properties of hydrogen cyanide prepared by the reaction between mercurous cyanide and HCl and reported that a mixture of the dry mercurous cyanide and chlorine kept in the dark for a long time, showed no reaction (Gay-Lussac, 1811, 1815). Nevertheless, when exposed to sunlight, the color of chlorine disappeared completely within 12 hours and the mercuric cyanide adhered to the walls of the flask like if it was wet; the remaining gas phase was a mixture of air and chlorocyanic acid that smelled strongly like chlorine but did not bleach litmus paper. Gay-Lussac found that a mixture of equal volumes of cyanogen and chlorine showed no reaction in the dark. Exposure to sunlight resulted in the formation of a white vapor and a large number of yellow liquid oily drops. Mixing the gas with mercury left only cyanogen. He asked if it was possible that under these circumstances a particular substance was present, which was then destroyed by mercury (Gay-Lussac, 1815).

Afterwards, George Simon Sérullas (1774-1832) repeated Gay-Lussac's experience and found that addition of a very small amount of water (smaller than the amount required to dissolve the cyanide) allowed the reaction to take place in the dark (Sérullas, 1827). After 10 to 12 hours the gas phase was completely discolored. Placing the product in a freezing mixture resulted in the crystallization of chlorocyanic acid; in addition, it was also found that the mercurous chloride had been oxidized to mercuric chloride. The same reaction conducted in the presence of sunlight resulted in the formation of additional ammonium chloride crystallizing on the walls of the flask, the yellow oily liquid mentioned before, and traces of cyanide chloride and CO2. Sérullas separated the yellow liquid and found that it released an extremely piquant odor, highly uncomfortable and strongly irritating the eyes. This liquid was heavier than water and insoluble in it, very soluble in alcohol, and did not turn green a solution of ferric chloride. In contact with water, it showed no immediate reaction but after some time it became concentrated HCl, while releasing nitrogen and CO2 and depositing a white crystallizable substance, smelling like camphor, soluble in alcohol, and decomposing into carbon chloride. These results led Sérullas to assume that the yellow liquid was a mixture of nitrogen chloride, a liquid of cyanogen chloride, and ethylene tetrachloride, C2Cl4 [carbon perchloride, discovered by Michael Faraday in 1820 (Faraday, 1821)]. Sérullas mentioned that the dangerous properties of the yellow liquid and of its volatilization decomposition products had led him to stop investigating it (Sérullas, 1827).

Bouis reported that he had prepared the yellow oil by a modified procedure: he boiled with chlorine a saturated aqueous solution of mercurous cyanide, in the presence of sunlight (Bouis, 1845, 1847a). The resulting yellow oily liquid, well washed with distilled water, was heavier than water and insoluble in it and soluble in alcohol and ether. It had a caustic taste and an extremely irritating odor, which provoked intensive lacrimation. It burned with a red flame, leaving a light residue originating from the decomposing carbon chloride. After a long contact with water, it deposited crystals of ethylene tetrachloride, losing part of its color. It was very explosive. Repeated elemental analysis indicated that, it contained, by weight, 10.47 to 10.92% carbon, 8.34 to 8.43% nitrogen, and 78.49 to 78.89% hydrogen, corresponding most probably to the formula C8N4Cl8,C4Cl6. According to Bouis the first term was a result of the presence of the elements of cyanogen with an excess of chlorine. More than that, it was possible to assume the formation of a second molecule of the same composition, which under the influence of water decomposed into CO2 and nitrogen, leaving ammonium chloride in solution, and carbon tetrachloride, according to

[TeX:] C8N4Cl8 + H8O8 = C4O8 + N2H8Cl2 + N2 + C4C15

The nascent carbon chloride reacted with C8N4Cl8 to yield a compound more stable, C8N4Cl8 + C4C16.

Bouis studied the effect of different factors and agents upon the yellow liquid. Under the action of moderate heat, it begun to distill while releasing nitrogen mixed with CO2. The distillate was a colorless liquid, which after some time, deposited a crystalline material. The liquid phase had a very strong odor, was insoluble in water and soluble in alcohol and ether and boiled initially at about 85 oC. It released gas continuously, leading to an increase in the boiling point. Analysis of the crystalline mater indicated that it contained, by weight, 10.13% carbon and 89.6% chlorine, corresponding to ethylene tetrachloride (actually 14.48% carbon, and 85.52% chlorine). The yellow liquid reacted explosively with potassium, with a significant increase in temperature. Bouis wrote that it was enough to rub a glass rod wetted with the yellow liquid against a piece of potassium, to generate a series of explosions. Mixing the yellow liquid with an ammonia solution resulted in the release of a gas having a strong penetrating odor, while the walls of the vessel became covered with a white substance soluble in water and yielding a precipitate of ammonium chloride. These and other results led Bouis to postulate the existence of three cyanide chlorides: protochloride (CNCl), bichloride (CNCl2), and terchloride (CNCl3), acting the part of acids and combined with chloroform (Bouis, 1845, 1847a).

Bouis added that the above research had led him to study the reaction of methanol with chlorine (Bouis, 1847b). In 1837 Georges Aimé (1810-1846) reported that passing a stream of chlorine through a solution of mercurous cyanide in methanol and condensing the passing vapor, yielded a liquid containing methanol and an ethereal liquid, which could be separated by adding water. This new liquid boiled below 50 oC, had a relative density of 1.2, was soluble in alcohol and in ether, and was easily decomposed by low heat. It smelled like cyanogen chloride, tasted like hydrogen cyanide and irritated the eyes strongly. According to Aimé it was a mixture of cyanogene chloride and ether, of formula C2NCl + C8H8 + H2O. The analogy between ethanol and methanol suggested the existence of methyl chlorocyanate, a fact confirmed by experience. Passing a stream of chlorine through a solution of mercurous chloride in methanol, under low heating, resulted in a product similar to the previous one. It boiled above 50 oC, had a relative density of 1.25, was destroyed by ammonia and water, its formula could be represented by C2NCl + C4H4 + H2O, and affected the senses in the same manner (Aimé, 1837).

Bouis repeated the work of Aimé and observed the disengagement of CO2, HCl, and cyanogene chloride (Bouis, 1847b). The liquid deposited a large amount of ammonium chloride or alembroth salt (a mixture of ammonium chloride and mercury chloride), an additional crystalline substance, and a red or yellow oily liquid. Analysis of the crystalline salt pointed to the possibility that it was methyl chlorocyanate, but the absence of nitrogen in these crystals and in the yellow liquids pointed to a different result. Bouis also looked into the possibility that mercurous cyanide was not necessary for the production of the crystals, that is, the crystals were the result of the direct action of chlorine upon methanol. The large number of experiments he carried on for this purpose proved this to be true. Mercurous cyanide instead of being part of the process, was actually a nuisance, it originated cyanogene chloride with its deleterious effects on the operator, and ammonium chloride and alembroth salt, which were extremely difficult to separate from the crystals. This conclusion led him to the next series of experiments in which the chlorine was reacted alone with methanol (Bouis, 1847b).

Streaming chlorine through methanol in the presence of sunlight showed that the gas was completely absorbed, the liquid became hot and HCl was released together with a gas burning with a green flame, followed by release of CO2. An oily phase appeared at the bottom of the flask, which after several hours deposited an abundant quantity of a crystalline solid. Addition of more chlorine resulted in the solution of the crystals. The oily liquid was washed with water and then dried over calcium chlorine. Elemental analysis indicated that it contained, by weight, 22.25% carbon, 1.89% hydrogen, 66.15% chlorine, and 9.71% oxygen, corresponding to the formula C6H3O2Cl3. The crystalline phase was insoluble in water and very soluble in alcohol and ether and melted at 50 oC. The crystals were stable in contact with air, were not attacked by KOH, ammonia, and dry chlorine in the dark. Elemental analysis indicated that its composition corresponded to the formula C10H10O4Cl2, which Bouis named methylene chloromesitate (Bouis, 1847b).

Iron and steel

Bouis reported that the general Arthur Jules Morin (1795-1880) had requested from him to compare the composition of steel from different sources, to see if something could be learned to improve the fabrication of this material (Bouis, 1861). In his work he passed a stream of dry hydrogen through a long column of pumice stone heated red and then through many test tubes filled with pieces of fused calcium chloride. He also prepared hydrogen by the decomposition of CO, using sodium carbonate mixed with lime. The purified and dried hydrogen was led thorough a large tube ending in two porcelain branches, one connected to the sample being tested and the other serving as blank. Both branches were located in the same furnace, heated under the same conditions, and terminating in two Will tubes containing diluted sulfuric of known composition. Comparison of the final composition of the sulfuric acid allowed an exact determination of the ammonia, and hence, of the nitrogen (Bouis, 1861).

Bouis reported that white vapors appeared every time the iron or the steel was heated in an atmosphere of hydrogen. These vapors crossed the acid solutions without condensing; they smelled strongly like burning organic matter and emerged only for a short time. All the steel samples tested generated ammonia from the nitrogen located on the surface of the metal, as shown by the fact that after a long run, the barrels were polished and tested again, and seen to release the same amount of ammonia as in the first operation. This finding yielded the total amount of nitrogen present only when operating with very thin wires, or after an extremely long run. Steel was found to contain very small amounts of nitrogen while iron contained substantially larger amounts. Bois presented his results in a table detailing the weight, origin, and shape or the sample (spiral, wires, plates, fragments, etc.), duration of the experiment, nitrogen content, and observations; and reached the following conclusions: (a) Krupp steel contained very small amounts of carbon and this carbon seemed to be in same form through out the metal; (b) iron contained much larger amounts of carbon; streaming hydrogen through the iron did not transform it into steel. The hydrogen made the iron very crystalline, fragile, and did not maintain magnetism. Worked while hot, iron lost his crystalline state and returned to the original fibrous one; (c) tempered steel remained malleable after a long treatment with hydrogen; and (d) using wet hydrogen might be useful because it eliminated foreign impurities such as sulfur and phosphorus (Bouis, 1861).