Mi SciELO

Servicios Personalizados

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista Cubana de Farmacia

versión impresa ISSN 0034-7515

Rev Cubana Farm vol.47 no.3 Ciudad de la Habana jul.-sep. 2013

PRODUCTO NATURAL

Development and evaluation of tablets from spray dried extract of yerba mate (Ilex paraguariensis St. Hil A)

Desarrollo y evaluación de las tabletas de extracto seco por aspersión de yerba mate (Ilex paraguariensis St. Hil A)

MSc. Juliana Roman, I Dra. Cassia Virginia Garcia,II, III Dra. Andreas Sebastian Loureiro Mendez,II Dra. Fabiana Ernestina Barcellos da SilvaI, II

I Universidade Regional Integrada do Alto Uruguai e das Missões-URI. Erechim, RS, Brasil.

II Núcleo de Pesquisa em Fármacos e Medicamentos-Universidade Federal do Pampa-UNIPAMPA. Uruguaiana, RS, Brasil.

III Faculdade de Farmácia, Universidade Federal do Rio Grande do Sul-UFRGS. Porto Alegre, RS, Brasil.

ABSTRACT

Introduction: yerba mate (Ilex paraguariensis St. Hil A) is a South American plant species of Aquifoliaceae family. The presence of methylxanhtines and clorogenic acids was reported in this species. These compounds have antioxidant activity and could be included in tablets, a pharmaceutical form presently unavailable in the market.

Objective: to develop tablets containing yerba mate spray dried extract.

Methods: the tablets were produced by direct compression with yerba mate dried extract. The dried extract was evaluated for yield, repose angle, compressibility index, residual moisture and caffeine content. The tablets were evaluated in the following parameters: external appearance, weight, hardness, friability, disintegration and caffeine content.

Results: the tablets complied with the general pharmacopoeial specifications.

Conclusions: this method is effective to produce tablets containing spray dried extract from yerba mate.

Key words: Ilex paraguariensis St. Hil. A, caffeine, tablets, direct compression, yerba mate.

RESUMEN

Introducción: la yerba mate (Ilex paraguariensis St. Hil A) es una planta de América del Sur, de la familia Aquifoliaceae. Para esta especie se informó la presencia de ácidos clorogénico y metilxantinas. Estos compuestos tienen actividad antioxidante y podría incluirse en tabletas, una forma farmacéutica que no está disponible.

Objetivo: desarrollar comprimidos que contienen extracto seco por aspersión de yerba mate.

Métodos: se produjeron comprimidos por compresión directa. Se determinaron al extracto seco los parámetros de rendimiento, ángulo de reposo, índice de compresibilidad, humedad y contenido de cafeína, y a los comprimidos, apariencia externa, peso, dureza, friabilidad, desintegración y contenido de cafeína.

Resultados: los comprimidos cumplieron con las especificaciones generales planteadas en farmacopeas.

Conclusión: el método empleado es eficaz en la producción de comprimidos que contienen extracto seco de yerba mate.

Palabras clave: Ilex paraguariensis St. Hil. A, cafeína, tabletas, compresión directa, yerba mate.

INTRODUCTION

Ilex paraguariensis St. Hil. A is a herbal medicine of South America, family Aquifoliaceae. Currently, its aerial parts are used for beverage preparations ("chimarrão" and "tererê"). These beverages are prepared by infusion or decoction of commercial product denominated "yerba mate", obtained after industrial processing of aerial part of Ilex paraguariensis St Hill A.

The industrial processing of Ilex paraguariensis St. Hill A involves different stages (green leaves, "zapecado", drying, forced or natural aging) which can modify the qualitative and quantitative composition and the pharmacological activities. According to various studies, Ilex paraguariensis St Hill A is rich in a variety of bioactive compounds (such as saponines, polyphenols and methylxantines) and has several beneficial effects to the organism.1-8 The bioactive compound (methylxanthines class) present in highest concentration in leaves is caffeine. This way, caffeine content in this material has been broadly studied.9,10 Caffeine levels in Ilex paraguariensis St Hill A ranging from 0.16 % in old leaves to 1.4 % in young leaves.11 According Isolabella et al. main compounds, caffeoyl derivatives, methylxanthines and flavonoids obtained after "zapecado", drying and aging stages possess higher content of biologically active principles when compared with green leaves.12

Caffeine levels in Ilex paraguariensis St Hill A may be increased in processed yerba mate due humidity and temperature conditions used in industrial process.13 Thus, processed yerba mate can be serving as a source for obtaining extracts that can be used in tablets production. For this potential requires that this extract is in powder form. Spray-drying, a well-characterized pharmaceutical operation is ideally suitable to producing solid amorphous dispersions due to its rapid drying kinetics.14,15 According to different authors the physical and chemical properties of particles can be changed by varying the spray drying parameters.16,17

Thereafter, the dried extracts used in solid oral dosage forms productions allowed direct incorporation in blended and posterior direct compression. Thus it is possible to produce tablets (provided with appropriate technological conditions) from only two processes: blend and compression. The direct compression method is fast and simple, but requires the use of excipients with good flow and compressibility properties, such as microcrystalline cellulose, magnesium stearate and colloidal silicon dioxide.18 Tablets obtained by direct compression are considered an attractive alternative to traditional granulation (wet and dry granulation), since it requires fewer steps and saves time and costs.19

Thus, the objective of this study is to develop tablets containing spray dried extract from yerba mate by direct compression.

METHODS

Solvents, reagents and pharmaceuticals excipients

Reference substance used was caffeine provided by Sigma-Aldrich (purity in 99.0 %). For dried extract and tablets developments the following materials were used: microcrystalline cellulose PH 101 (Valdequímica, Brazil), magnesium stearate (Valdequímica, Brazil), calcium phosphate dibasic anhydrous (All Chemistry, Brazil), colloidal silicon dioxide (Viafarma, Brazil), mannitol (Gênix, Brazil) and talc (All Chemistry, Brazil). Metanol was HPLC grade. Ultra pure water was supplied by a Mili-Q water purifier system from Millipore (Bedford, MA, USA). All of them were from pharmaceutical grade.

Equipment

The equipment used were: Disintegration apparatus, model 301 BC (Nova Etica, Brazil); Analytical balance, model BL 210S (Sartorius, Brazil); Compression machine Monopress model LM-1 (Lemaq, Brazil); Durometer, model 298 (kgf/Nova Etica, Brazil); Friability apparatus, model 300 (Nova Etica, Brazil); LabPlant Laboratory Scale Spray dryer model SD-O6 (Keison, England); Extractor by percolation (Bialetti, Italy); High efficiency liquid chromatography (HPLC) equipment model 1100S (Agilent, United States); V-blender model MP-3 (Erli, Brazil) an Infrared balance model ID-200 (Marte, Brazil) .

Plant material

The Rei Verde Yerba Mate (Ervateira Rei Verde/RS-Brasil) avaliable in local market, containing leaves:branches ratio of 70:30 (w/w). This yerba mate passed through all stages of industrial processing (blanching, drying, milling and aging) and was used to aqueous extract production. Aqueous extracts were prepared with this material in order to compare to the preparation used by people.

Dried extract development

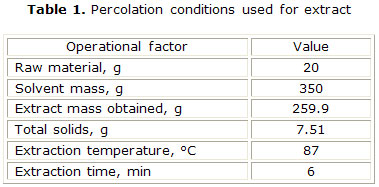

Initially, aqueous extract was produced by percolation of processed yerba mate in appropriate extractor according to the specifications described by Valduga.20 This equipment consists of lower chamber to solvent, an intermediate compartment to sample and a top compartment to extract. The extraction was performed using water and processed yerba mate in an extractor at 87 °C. The extracts obtained were clarified in a lab scale continuous centrifuge, which retained most of the insoluble solids. Data on percolation conditions and drug:solvent ratio are shown in table 1.

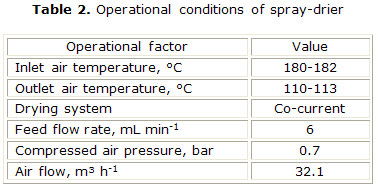

A dried extract was prepared by spray drying of the suspension containing 15 % (w/w) colloidal silicon dioxide and 75 % (w/w) aqueous extract. During the atomization procedure, the suspension was mixed with a magnetic stirring bar and dried using a spray-dried model LabPlant SD-O6. A summary of operational conditions employed during spray-drying is shown in table 2.

The dried extracts were weighted to analyze the total extract yield and yield of caffeine. The reported results, as illustrated in equations 1, 2 and 3, include the total extract yield (%), the yield of caffeine from the yerba (%), and the content of caffeine (%) in dried extract respectively:

All reported weights and percentages are dry basis unless specified otherwise. All the extraction trials were carried out in triplicate. The following parameters were evaluated in dried extract: bulk density, tapped density, repose angle, compressibility index and moisture content. As caffeine is the major compound in extracts, it was chosen to evaluate the content and uniformity of formulations developed. The caffeine analysis was conducted by HPLC.

Blends containing dried extract

Three blends were tested for repose angle and compressibility index. For blend time determination, the formulations were blended in V-blender. Three aliquots were taken at 10, 15 and 20 min in random localization. The aliquots were transferred to 100 mL volumetric flask and completed with mobile phase. After shaking, samples were filtered and caffeine determination performed by HPLC. The mean and standard deviation were obtained in each time period. The blend time chosen was that presented lowest standard deviation. The selected blend was compressed by direct compression.

Tablets development

The following parameters were evaluated in tablets: external appearance, hardness, friability, disintegration, assay and content uniformity. The validation of methodology for tablets assay was performed.

Samples preparation

Caffeine content in dried extracts, blends and tablets was performed by validated HPLC method. Samples were weighed (equivalent weight of 5 mg caffeine) and brought up to 100 mL with mobile phase. After 20 min in ultrasonic bath, samples were filtered and diluted in mobile phase.

High performance liquid chromatography

The HPLC analysis were carried out on a AGILENT 1100S System (USA) consisting of a separation module with integrated column heater and auto-sampler, while detection was carried out on a photodiode array detector coupled online with a multi-wavelength ultraviolet detector. Separation of compounds was carried out on a C18 column (Zorbax; 250 x 4.6 mm; 5 µm) and UV detection was carried out using 280 nm. Mobile phase was composed of methanol and water (40:60) and injection volume was 10 µL. The software for control of equipment and data acquisition was CHEMSTATION.

RESULTS

Dried extract development

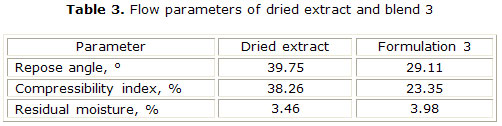

The aqueous extract obtained by percolation presented green color and characteristic smell. Data on aqueous extract are shown in table 1. This extract was used in dried extract preparation. Colloidal silicon dioxide was used in dried extract preparation. The concentration used was 15 % over the total solids present in the aqueous extract. The appearance of macroscopic nebulized obtained was finely powdered with pale green/yellow, characteristic odor and non-adherent. The yield obtained was 75.17 %. The expected caffeine content of dried extract, estimated by mass balance and neglecting any losses, was 13 mg g-1. Data on flow parameters of dried extract are show table 3. The total extract yield (%), the yield of caffeine from the yerba (%) and the content of caffeine (%) in dried extract were 75.17, 1.72 and 1.29, respectively.

Characterization and quality control of dried extract

The repose angle and compressibility index of dried extract are showed in table 3. Adjuvants have been added at dried extract to improve the flow characteristics, as described in table 4. Other parameters were evaluated in dried extract, as residual moisture and caffeine content. The residual moisture content presented on dried extract was 3.5 %. In analysis by HPLC, caffeine content in dried extract was 1.3 % (w/w).

Tablets development

The three developed blends were evaluated for repose angle and compressibility index. The formulation with better repose angle and compressibility index was blend 3. This formulation was selected for tablet development and yours flow parameters are shown in table 3. Blend time for selected formulation was 20 min. After blended, the powders were compressed, presenting suitable hardness after machine adjustment. Yerba mate tablets presented uniform color and concave shape, without irregularities in the surface. The tablets were obtained with 12 mm diameter, 3.5 mm thick and 702.4 ± 6.2 mg (CV= 0.88 %) average weight. Hardness (12.35 kgf/Nova Etica model 298) and friability index obtained (0.22 %) indicates a high friction resistance in coating operations, packaging and transport. The tablets were tested using disintegration medium 0.1 N HCl and distilled water. In both media, the sample showed complete disintegration within 20 min. The average content obtained was 103.5 ± 1.47 %, considering a theoretical quantity of 5 mg caffeine per tablet. The results for content uniformity ranged from 101.25 to 105.86 % of caffeine with CV= 1.51 %, which is in accordance with the specifications.21

DISCUSSION

The dried extract showed to have suitable characteristics for tablets production. Values for repose angle between 25° and 30° characterize a good flow.22,23 Thus, the dried extract obtained can be classified as acceptable material flow. However, the addition of appropriate adjuvants improved the blend characteristics, allowing the powder direct compression without a prior granulation stage. The addition of colloidal silicon dioxide in liquid extracts is usual to reduce the adherence of the material to the equipment and improve the dry powder shape (spherical), size distribution and flowability.24 In accordance with Pingali et al (2009) simultaneous presence of colloidal silicon dioxide and talc leads to substantial decreases in cohesiveness, causing major improvements in flowability of powder.25 These excipients were included in formulations and produced blends with acceptable flow.

The residual moisture is an important parameter to be evaluated during the development of solid dosage forms, particularly extracts obtained from plants. High levels of residual moisture can cause changes in physical characteristics such as size distribution and flow.26 The analysis of caffeine from the spray-dried extract and solid dosage form are important to evaluate the overall process efficiency and reproducibility because this metabolite can undergo thermal or chemical degradation during the process. This way, residual moisture and caffeine content were evaluated and considered appropriate to tablets production.

The tablets were produced without lamination and capping defects. Average weight was considered appropriate in accordance with the recommendations of Brazilian Pharmacopoeia.21 The hardness was considered appropriate and the value (12.35 kgf) can be associated with compressive forces because of large mannitol (thinner) and microcrystalline cellulose (diluent and binder) amounts.27

The tablets containing dried extract of yerba mate were obtained with appropriate technological characteristics. The dried extract showed good flow characteristics favoring its use in tablets production by direct compression. The tablets developed are appropriate for production in large scale, since all technological tests were in accordance with pharmacopoeial specifications (weight, appearance, hardness, friability, disintegration, content uniformity and caffeine content). Studies involving in vivo and in vitro bioavailability are necessary for registration this new pharmaceutical product.

Acknowledgements

The authors thank FURI for financial support.

REFERENCES

1. Bracesco N, Sanchez AG, Contreras V, Menini T, Gugliucci A. Recent advances on Ilex paraguariensis research: minireview. J Ethnopharmacol. 2011;136(3):378-84.

2. Heck CI, de Mejia EG. Yerba Mate Tea (Ilex paraguariensis): a comprehensive review on chemistry, health implications and technological considerations. J Food Sci. 2007;72(9):R138-51.

3. Gugliucci A, Bastos DHM, Schulze J, Souza MFF. Caffeic and chlorogenic acids in Ilex paraguariensis extracts are the main inhibitors of AGE generation by methylglyoxal in model proteins. Fitoterapia. 2009;80:339-44.

4. Mosimann ALP, Wilhelm-Filho D, da Silva EL. Aqueous extract of Ilex paraguariensis attenuates the progression of atherosclerosis in cholesterol-fed rabbits. BioFactors. 2006;26(1):59-70.

5. Bastos DHM, Ishimoto EY, Marques MOM, Ferri AF, Torres EAFS. Essential oil and antioxidant activity of green Mate and Mate tea (Ilex paraguariensis) infusions. J Food Comp Anal. 2006;19:538-43.

6. Paganini Stein FL, Schmidt B, Furlong EB, Souza-Soares LA, Soares MC, Vaz MR, Mucillo Baisch AL. Vascular responses to extractable fractions of Ilex paraguariensis in rats fed standard and high-cholesterol diets. Biol Res Nurs. 2005;7(2):146-56.

7. Gorzalczany S, Filip R, Alonso MR, Miño J, Ferraro GE, Acevedo C. Choleretic effect and intestinal propulsion of `mate' (Ilex paraguariensis) and its substitutes or adulterants. J Ethnopharmacol. 2001;75:291-4.

8. Silva RA, Bueno ALS, Gallon CW, Gomes LF, Kaiser S, Pavei C, Ortega GG, Kucharski LC, Jahn MP. The effect of aqueous extract of gross and commercial yerba mate (Ilex paraguariensis) on intra-abdominal and epididymal fat and glucose levels in male Wistar rats. Fitoterapia. 2010;82:818-26.

9. Athayde ML, Coelho GC, Schenkel E. Populational diversity on methylxanthines content of Maté (Ilex paraguariensis A. St. Hill., Aquifoliaceae). Lat Am J Pharm. 2007;26(2):275-9.

10. Athayde ML, Coelho CC, Schenkel EP. Caffeine and theobromine in epicuticular wax of Ilex paraguariensis A. St.-Hil. Phytochemistry. 2000;55(7):853-7.

11. Rates SMK. Metilxantinas. In: Simões CM, Schenkel EP, Gosmann G, Palazzo de Mello JC, Mentz LA, Petrovick PR, editors. Farmacognosia: da planta ao medicamento. Porto Alegre: UFSC/UFRGS; 2004. p. 199-222.

12. Isolabella S, Cogoi L, Lopez P, Anesini C, Ferraro G, Filip R. Study of the bioactive compounds variation during yerba mate (Ilex paraguariensis) processing. Food Chemistry. 2010;122(3):695-9.

13. Turner S, Cogoi L, Isobella S, Filip R, Anesini C. Evaluation of the antioxidant activity and polyphenols content of Ilex paraguariensis (Mate) during industrialization. Adv J Food Sci Technol. 2011;3:23-30.

14. Dobry DE, Setell DM, Baumann JM, Ray RJ, Graham LJ, Beverinck RAA. A Model-Based Methodology for Spray-Drying Process Development. J Pharm Innov. 2009;4(3):133-42.

15. Oliveira OW, Petrovick PR. Secagem por aspersão (spray drying) de extratos vegetais: bases e aplicações. Rev Bras Farmacogn. 2010;20(4):641-50.

16. Rattes ALR, Oliveira WP. Spray drying conditions and encapsulating composition effects on formation and properties of sodium diclofenac microparticles. Powder Technol. 2007;171(1):7-14.

17. Esposito E, Roncarati R, Cortesi R, Cervelatti F, Nastruzzi C. Production of Eudragit microparticles by spray-drying technique: influence of experimental parameters on morphological and dimensional characteristics. Pharm Dev Technol. 2000;5(2):267-78.

18. Silva FEB, Ziech C, Pavoni GD, Pasquali R. Desenvolvimento de comprimidos contendo fluconazol por compressão direta. Lat Am J Pharm. 2009;28(4):604-8.

19. Al-Mohizea AM, Ahmed MO, Al-Jenoobi FI, Mahrous GM, Abdel-Rahman AA. Formulation and evaluation of dried yeast tablets using different techniques. Eur J Pharm Biopharm. 2007;67(1):253-9.

20. Valduga AT, Battestin V, Finzer JRD. Secagem de extratos de erva mate em secador por atomização. Ciênc Tecnol Aliment. 2003;23(2):184-9.

21. Brasil. Farmacopéia Brasileira. II Vol. Brasília: Agência Nacional de Vigilância Sanitária (ANVISA); 2010.

22. Lachman L, Lieberman HA, Kanig JL. Theory and practice in the pharmaceutical industry. Lisboa: Calouste Gulbenkian; 2001.

23. Aulton ME. Delineamento de Formas Farmacêuticas. Porto Alegre: ARTMED, 2005.

24. Runha FP, Cordeiro DS, Pereira CAM, Vilegas J, Oliveira WP. Production of dry extracts of medicinal Brazilian plants by spouted bed process: development of the process and evaluation of thermal degradation during drying operation. Food Biop Process. 2001;79:1-9.

25. Pingali KC, Saranteas K, Foroughi R, Muzzio FJ. Practical methods for improving flow properties of active pharmaceutical ingredients. Drug Dev Ind Pharm. 2009;35(12):1460-9.

26. Farias MR. Avaliação da qualidade de matérias-primas vegetais. In: Simões CM, Schenkel EP, Gosmann G, Palazzo de Mello JC, Mentz LA, Petrovick PR, editors. Farmacognosia: da planta ao medicamento. Porto Alegre: UFSC/UFRGS, 2004: p.199-222.

27. Pasqualoto KFM, Funck JAB, Silva FEB, Kratz C. Development and Evaluation of Amoxicillin Formulations by Direct Compression: Influence of the Adjuvants on Physicomechanical and Biopharmaceutical Properties of the Tablets. Acta Farm Bonaerense. 2005;24(1):39-47.

Recibido: 23 de marzo de 2013.

Aprobado: 29 de mayo de 2013.

Fabiana Ernestina Barcellos da Silva. Faculdade de Farmácia, Universidade Federal do Río Grande do Sul-UFRGS. Porto Alegre, RS, Brasil. Correo electrónico: fabianasilva@unipampa.edu.br