INTRODUCCIÓN

Most important building installation is air conditioning system. Among the several reasons that support the above this affirmation are investments, exploitation and maintenance. Between 10 and 20% of the total cost in centralized installations in new buildings are constituted by investment costs. Most important building energy costs are had in exploitation, even higher than the energy consumption in lighting and other electrical consumptions. On the other hand, remarkable dedication of personnel specialized is demanded by maintenance and conservation considering the component costs. Finally, due to the high incidence of service failures, functional aspect is considered.

Water cooling machines or “chiller” are All-Water centralized systems, which in turn is a type of air conditioning scheme that allows to satisfice the interior space thermal conditioning demand of buildings. They are mainly characterized by using water as a heat carrier fluid, extracting heat from the medium and, consequently, lowering the air temperature by means of heat thermo-transfer process. Many advantages related to operation, reliability and efficiency are offered by these systems while compared to individual acclimatization systems.

The initial investment is about 2.2 times greater than individual climate control systems, but comfort is achieved are superior is and also offers quieter operation, and promotes internal and external aesthetic building. Smaller space compared to All-Air systems is required by thermal distribution, what is very suitable for limited space building. Simultaneous control of the different thermal zones, as well as air conditioning and heating circuits are allowed by them. Finally, these systems are used in large hotels, restaurants, cinemas, theatres, shopping centres, hospitals and other public buildings. They are usually installed during the construction of the building, although in some cases they are installed during remodelling of existing buildings. Water cooling machines or “chiller” are plant central axis, which in turn are made up of several machines and are responsible for 60 % of the energy consumption in a building [1].

The chiller can be operated by the electrical compression cycle or a thermal sorption cycle. Machines that use compressors can be generally classified as: reciprocating, centrifugal, screw and scroll compressors. In the case of the sorption cycle, they can be absorption or adsorption. These chillers are available in different ranges in terms of cooling capacity according to the type of specific compressor and the coefficient of performance Chiller plant design addresses to determining the system cooling capacity and its configuration. According to [2], when designed improperly a plant, the efficiency of each system element deviates from its optimal operation. In addition, they confirm that a common problem in engineering field is the poor chiller plant design. The following aspects must be taken into account for the design of a plant:

Total plant capacity

Total, of chillers to install

Distribution of cooling capacity

Hydraulic arrangement

Defining these elements correctly is a key moment that defines the energy efficiency of an installation since the variability of the consumption of a plant composed of chillers of different types and / or capacity, can reach up to 69% [3]. Thus, the general research objective is the analysis of state of art of aspects related to chiller plants design to establish guidelines for future improvements in design methodologies used at present.

Total chiller plant capacity

The calculation of the building's cooling load is the first step in a chiller plant design which it can be estimated through engineering rules, for example, tons of refrigeration per area unit or by heat transfer methods. Among others, this is the case of the transfer method or time series. Approximately 10-20 % of total plant capacity higher than peak demand obtained from thermal load calculation is suggested by ASRHAE Fundamentals in a conventional plant design proposed [3]. This security factor (SF) is used in order to avoid under-dimensioning risk. SF has been criticized by some authors who report that chiller plants oversizing is the main malfunction cause and that they work under partial load regime. [4-6]. On the other hand, hours not taken into account ("unmet hours") lower than 300 is another criterion stated by ASHRAE Standard 90.1-2010 that influences in the total system capacity.

Another action that increases the installed load is the chillers redundancy. Sometimes, multiple chillers plus a redundant one as reserve are designed, in order to guarantee acclimatization extra load in case of system failure, which provides substantial robustness. A significant increase in failure rate of a non-redundant system with respect to a redundant one, from 1.3*10-6 to 2.4 * 10-2, respectively was determined by [7]. Adopting above provision is strictly necessary in some cases. according to [8], there are critical plants which serve in industries a rule N + 1 or N + 2 redundant chillers installation is required, such as case of data centers, considering the possibility of larger capacity chiller failures. However, no necessity of applying redundancy if there is in advance, a strict maintenance plan based on the risk of failure has been reported by some authors to apply redundancy. High cost of extra chiller uses in most of the plants that operate at full load in short periods of time during a year is stated by [9]. Possibility of redundancy elimination due to certain benefits that designers sometimes do not take into account was demonstrated by their study as the security factor itself and the design margin that manufacturers use in chillers. In addition, if necessary, smaller capacity chiller can be considered to perform this function.

At present, methods to more accurately determine the cold plant capacity through analysis and quantification of uncertainties have been employed by researchers. These analyses are based on several aspects: the typical meteorological day, which groups together a series of extreme meteorological data that rarely concur at the same time. More sensitive parameters in the final result of the thermal cooling load were stated by [5] and [10]: The heat gains derived from the equipment should not be the nominal power, according to manufacturer data; the degeneration of its functionality with respect to the time of use; the uncertainties generated by the composition of building materials and heat transfer phenomena; the possible changing nature of thermal demand over time; the uncertainties derived from the intermittent heat gains depending on the occupation of the building, together with the internal gains associated with the use of the equipment. Also, quantifying redundancy as a type of uncertainty and applying it in the calculation of thermal load is recommended.

Mathematical representation of uncertainty spread according to their type was defined by [11]. In addition, those that most influence thermal demand was ordered considering its importance. Climate change impact on the uncertainties that are generated due to building thermal properties and internal heat gains were explored by [12]. Determining an increment of 122 % in thermal cooling loads and a decrease of 40 % in heating demand were defined by them as well as a 14 % growth in CO2 emissions for a baseline of 2050. Uncertainty analysis and multicriterial decision techniques for the selection of different components HVAC system capacity were combined by [13].

Range of cooling system capabilities (cooling towers) through uncertainty analysis were determined by [14]. Subsequently, the result, selecting the configuration with the lowest life cycle cost was optimized through an objective function. Finally, a methodology where chiller plant operation is evaluated under a range of loads obtained from the analysis of uncertainties was proposed by [15].

Only certain deterministic state is considered by conventional design methods. Otherwise, many more possible scenarios are probabilistically considered by related-to-uncertainties new design methods. According to [16], risk-based decision is favoured instead of deterministically sizing systems with a security factor. In addition to establish the “unmet hours” range according to installation and clients’ requirements, load frequency analysis is employed. But despite these advantages, very little attention has been devoted to this field of knowledge [17], due to high risk level involved, which, becomes unattractive from practical point of view.

Number of chillers to install

A basic configuration is a is a single chiller that provides the chilled water necessary to satisfy the thermal load. This configuration has the advantage of lower initial cost, but when any machine element (compressor, cooling tower, or pump) fails, the entire system is interrupted, unacceptable for most installations, especially those where the use of these systems is vital (laboratories, data centres, hospitals, hotels, etc.). Finally, installations are susceptible to work at partial loads. Installation of multiple chillers is more common than one. Plant composed of N+1 chillers is indicated as a mandatory rule what ensure system reliability. Thermal demand can vary over a wide spectrum in a multiple chillers plant if it has an appropriate capacity, thus, operation can be alternated and works at maximum capacity and/or efficiency depending on the type of machine and this way, conserves energy.

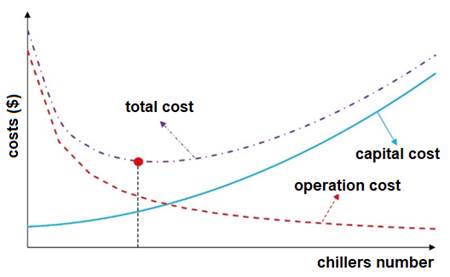

That increase in equal capacity chillers in a plant benefits efficiency increase in and energy consumption decrease was showed by [18]. On the other hand, that large capacity plant must contain at least three chillers was reported by [19]. However, space-related limitations may affect the decision. In addition, plant total cost is another influence factor, see figure 1. This may be due to the increase in the rest of the elements that constitute it, for example, pumps, pipes, among others.

Cooling capacity distribution between chillers.

A plant can be configured in two ways, with symmetric or asymmetric chillers. Symmetrical chiller plant is when all machines have the same nominal capacity. This configuration is the most used in practice; for example, from 50 chiller plants studied, 44 were of symmetrical configuration was reported by [18]. It has the advantage of ease maintenance because of sharing common elements. On the other hand, its main disadvantage lies in the low plant efficiency while working at partial loads. Asymmetric configuration are different capacity chillers. More system efficient adjustment to load variations is allowed to achieve with this configuration and it can represent a saving potential. According to [21], plant energy consumption can decrease by 10.1%.

At present, load distribution between chillers is carried out through recommendations, resulting very limited this field of study. For example, use of symmetric chillers, as can be seen in table 1. is recommended by ASHRAE 90.1-2013 standard [22]. On the other hand, that in buildings with a cold demand between 1050-7032 kW, should be used between 4-8 symmetric chillers is referred as policy by [23]. Similar statement is made by [9].

Table 1 Types and numbers of recommended chillers according to building demand (Table G3.1.3.7) ASHRAE (2013). Source [22]

| Building conditioned area (kW) | Number and types of chillers |

|---|---|

| ≤120 000 | 1 screw type chiller |

| > 120,000, <240,000 | 2 screw type chillers, symmetrical |

| ≥240,000 | 2 centrifugal chillers at least. (If more than two are used, they cannot be more than 800 TR, all symmetrical) |

According to [8], chiller amount, as well as their capacity distribution should depend on characteristics of the frequency distribution of installation cooling loads. If it is a building with large load diversification, several different capacities chillers are recommended, if it is one with a constant load, for example, industrial applications, database, etc., small chiller of large capacity can be used. However, how to distribute capacity is not proposed by this author.

On the other hand, using configurations composed of 80 % -20 % or 60 % -40 % of the total capacity is recommended by [24]. Following the criteria that, in applications such as hotels and offices, chillers can spend more than 50 % working under the partial load regime, above distribution was first endorsed by [25]. 30 % -70 % ratio in the case of laboratories was suggested by [26], as another proposal. That none of the studies presented provide a methodology or reveal the analysis prior to the suggested recommendations, is specified. Some specific configurations were evaluated by authors in isolated studies. For example, the use 3 chillers, two of equal capacity with a load distribution of 40 % each and one of less capacity, with 20 % of the load was developed by the American company CARRIER [27], as a study case working with the lowest capacity, and depending on cold need increase, the other two machines come into operation, with the lower capacity acting as a starting and reserve equipment, is ensured by this configuration. The energy performance of two configurations, one consisting of 7 symmetric chillers and another consisting of an arrangement of 5 large capacity symmetrical chillers (16 % of the total capacity each) and two of smaller capacity (8 % of the load), is compared by [2], Saving of 1.6 % is showed by results compared to the classic configuration of symmetric chillers.

Hydraulic arrangement between chillers.

A plant can be configured in three different ways: series, parallel or mixed chillers. A hybrid or mixed configuration is when a series of chillers are configured in series, while operating in parallel with another arrangement of chillers also configured in series. Although there is no general criterion about which provision is the best to use (since there are different design, exploitation and external factors that determine the advantages and disadvantages of each interconnection form), most plants are interconnected in parallel [28].

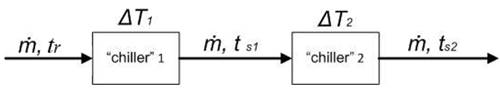

The same flow of ice water circulates through the chillers with series configuration (see figure 2). High temperature difference values are achieved between the outlet and the return of the ice water. From the thermodynamic point of view, intermediate fluids properties do not influence total system load. Mass flow of ice water, the return and supply temperatures of ice water are represented in figure by ṁ(kg/s), Tr and Ts (oC), respectively and ΔT is the temperature difference between them.

The number of connected chillers is limited by excessive pressure drops in this configuration [29,27] It is a configuration that is rarely implemented, being advantageous only when the temperature difference is excessive or if the cooling load is stable [24]. On the other hand, in the parallel configuration (see figure 3), the supply temperature of each chiller inlet and outlet flows is identical. But mass flow on both machines may vary. The operation of number of needed chillers depending on the thermal demand of the building is allowed by this arrangement. In addition, continuous operation of one machine, in case of maintenance or unexpected failures is allowed, assuring an uninterrupted service.

Mass flow of the primary circuit of the plant is divided into two or more parallel flows, with one mass flow (ṁ1) and the other (ṁ-ṁ1). From the hydraulic point of view, this arrangement has the advantage that the pressure drops through the pipes are not as high as in the case of series-connected chillers. The pumping system can be designed in different ways. In constant flow chillers, they may have only one pump in the circuit; the disadvantage lies in mixing of currents when one machine is out of service, which causes ice water temperature increase at the evaporator inlet. As solution, valves can be used to isolate chiller circuit off and increase the flow in operating machine. Another solution is to use multiple pumps, one for each chiller.

Variable flow pump can be located in primary circuit or in secondary circuit, while keeping primary circuit constant. Because of the cost-benefit ratio, first configuration is widely recommended, in addition, since of relative simplicity, flexibility and operating stability. Significant improvement in system control individually is obtained by means of a variable flow system through the primary circuit. Savings around of 15% are obtained because flow variation depending on the load is allowed [8].

However, system has some limitations on the immediate response to rapid fluctuations in load and water flow, but it is a viable option when control of water temperature is not strict. Besides, because greater control instruments accuracy is required, cost is higher compared to a variable flow pump in the secondary circuit.

Finally, total system capacity only depends on ice water mass flow and inlet and outlet the system temperature, regardless of the type of arrangement that is made according to [28]. But the same does not happen with the energy consumption of the plant because energy efficiency is also a function of the arrangement if all the variables are kept the same in both cases. Energy consumption increases with increasing its mass flow. Series chillers can operate around 12.26 % more efficiently, depending on chilled water temperature output values. However, it is that installation comfort conditions are checked

Methodologies for chiller plants design.

That chiller plants design is based on two methodologies has found in literature review, as shown in figure 4: Traditional and robust or optimized methodologies are defended by several authors [4,6,14,15,30,31,32]

Considerations that have been previously analyzed in the design of the chiller plants is summarized by typical design as it can be seen in figure 4. Moreover, nominal capacity of each chiller is determined mainly according to the experience of the engineers or by the empirical rules. In addition, the analysis of its operation is carried out considering certain design state, generally critical working conditions. Robust design concept, figure 4 b), is begun to apply in the chiller plants design analysis from the research presented by the authors [4,30,31]. According to them, the objective of robust design is each optimal system design based on cost and effectiveness, which provides the ability to operate as efficiently as possible in all subjected operating conditions, particularly those of partial load. Optimal design will be obtained through achieving the ability to accommodate the load uncertainties and operating system reliability. The evolution of this new form of design is detailed below.

Asymmetric chillers configuration was evaluated by [33], using the genetic algorithm. COP, operating expenses and PLR were included in the objective function. None design methodology is provided by this paper. Nominal capacity as a fixed value is considered in order to propose an optimal configuration for each load profile analyzed without considering load profile variation as vital element to be taken into account in the design, and in this way evaluate configuration behavior in the three profiles presented. Determining the individual chiller capacity that make up the plant, through the statistical analysis of cooling load frequency distribution during an analysis period was suggested by [34]. That each chiller capacity must match load values that present highest frequency percentage was considered by authors. However, chosen configuration was not checked as well as presented histogram was based on actual load data, so methodology is only useful for operation plants replacement.

Histogram frequency construction simulation was used by [35], but only weather conditions as a variation element was considered maintaining a fixed heat gains value by occupation and equipment use. Analysis to determine nominal capacity distribution was not used but it was applied for energy evaluation of 4 proposed configurations. That nominal load distribution has greater influence on energy consumption than total plant chillers is showed by research.

Four configurations using hypothetical load profiles were evaluated by [36], however, variability that provide occupation and earnings associated with it was not added. Operation strategies that improved energy performance were added to the energy analysis. Analysis of individual each chiller behavior by using black box type mathematical models is another contribution. Other operating strategies that reflect plant interaction with building thermal demand were used by [23], in subsequent research, for example, a work sequence based on chiller capacity was applied by them. These authors were who first used COP-PLR curve for plant design analysis but did not use artificial intelligence to find optimal solution. Based on this type of analysis, similar studies were presented in [4,10,18,20,21].

Another contribution was proposed by [37], which implemented a sequence of previous work to the study in one proposed configuration according to the COP-PLR curve. According to load demanded smaller capacity chiller began to work. That best plant configuration was based on building type and surrounding weather conditions were demonstrated by them. Last advance in these researches was the incorporation of thermal load analysis through uncertainties. Frequency load chart to establish "unmet hours" range were used. Besides, other indicators were added to energy analysis to compare several alternatives, such as annual costs, capital and risk of failure by [31], and life cycle cost by [14]. In addition, maintenance costs were treated by [32]. Finally, work sequence technique based on cooling load was used.

Despite all these actions that have greatly improved plant design, there are still elements to consider. For example, nominal capacity of each chiller, balancing 10% of total system load was determined in previous studies. It evident that suggestions made by [34], has not had continuity.

Analysis of maximum possible alternatives, considering actual limits is not included in proposed methodologies, for example, required space, budget, etc. Finally, although these studies are described as optimal solutions, no optimization program is applied, using artificial intelligence tools that assurance that solution provided is certainly robust.

CONCLUSIONS

Chillers are centralized All-Water systems mainly characterized by using water as a heat carrier fluid; which offer many advantages related to operation, reliability and efficiency when compared to individual air conditioning systems. Total plant capacity, chiller number to be installed, cooling loads distribution and hydraulic chiller arrangement should be considered in chiller plants design. Recommendations are presented for each case. Chiller plants design traditional methodology only includes determining the maximum plant cold capacity and subsequently selecting chiller load distribution by means of rules or recommendations, which are: apply a SF; set an unmet hour; set an additional chillers (redundancy). The plant must contain at least two chillers; Configuring a symmetrical plant, and finally a parallel arrangement between them. The robust chiller plants design is a superior concept which involve thermo-economics analysis for selecting the element of the plant, achieving better results. But spite that chiller loads distribution is not determined through the study of cooling loads behavior. And the employ of optimal load analysis and optimal sequence analysis, described as optimal solutions, no optimization program is applied, using artificial intelligence tools that assurance that solution provided is certainly robust.