Introduction

The proper mechanization of sugarcane cutting has an important role in the entire agroindustrial process. It is evident in countries like Australia, Brazil, USA, South Africa, Taiwan, Thailand, Cuba and Venezuela, where integral technological process combines are used. There, the efficient operation of the base-cutter system, has a significant impact on the quality of the process, as well as on the losses of raw material and the longevity of the cane field (Max et al., 2012).

The introduction in Cuba of the CASE-IH 7000 harvesters established deep transformations in the harvesting, transportation and reception of cane in the industry. Studies conducted by Matos et al. (2010) and Daquinta et al. (2014) highlight the superiority of this technology. However, one of the main problems that affect the proper functioning of the harvesters is the durability of the base-cutter blades, caused by the accelerated wear of the cutting edge. That generates considerable losses of materials, resources and time, with the consequent decrease of production and the loss of a large quantity of means to repair or acquire new elements (Max et al., 2012; Li et al., 2013; Ma et al., 2014; Abd-El y Hemeida, 2015; Tahsin et al., 2016; Daquinta, 2017; Jamadar et al., 2017).

Recent studies show that wear negatively affects most of the mechanized processes that are carried out in agriculture, which cause annual losses with millions of dollars, especially in Cuba, where, today there is no study aimed at quantifying them, although research conducted last century concludes that this figure reached 200,000 pesos per year.

This author argues that the main cause of the substitution of 85% of the elements of agricultural machinery in Cuba is abrasive wear. That is influenced by factors such as geometry, chemical composition and hardness of the work organ's material, friction between the bodies, the contact with plants and fruits, the climatic and operation conditions, the speed of work, the size and nature of the soil particles, among others. He adds, that different authors have approached the phenomenon of the interaction tool of tillage - soil in recent years, which has represented a significant advance in the interpretation of the wear of this tribological pair; however, the pair segment cut-cane has been little studied.

In this sense, Daquinta et al. (2014) has reported the determination of tribological properties of different materials used in the manufacture of the harvesters cutting elements. Other authors such as Mello and Harris (2003), Mello (2005), Toledo et al. (2013), Mathanker et al. (2015) and Momin et al. (2017) have investigated the functional behavior of the base-cutter blades with different designs, edge geometries and impact angles.

The objective of this research is to evaluate the functional behavior of the BONEM base-cutter blades in the CASE IH 7000 sugarcane harvesters, by means of a flaw analysis and a field experimental test of wear determination in these tools, for the estimation of their work ability.

Methods

The evaluation was carried out in Ecuador Sugar Company of Baraguá Municipality, Ciego de Ávila Province, one of the largest producers of sugar in the territory, during the period from December 10, 2014 to March 30, 2015.

For the analysis of flaw, two CASE IH-7000 harvesting machines were selected, both working in the same fields under the same conditions. Here, the observance of the necessary requirements that must be met by the discrete variables presented in the results obtained from the statistical methods, published by Herrera et al. (2012) and Guerra et al. (2014) was taken into account. The evaluation was based on the IAGRIC standard: Quality Management System. Testing of Agricultural Machines. Exploitative Technological Evaluation (IAgric, 2013), to establish the organization of the process, the realization of the timing of the times and the creation of the local operation conditions, on which an experimental field test was carried out, in real operation conditions by means of the gravimetric method, to determine the blades wear. The statistical processing of the tests results was carried out with the help of SPSS 15.0 processor.

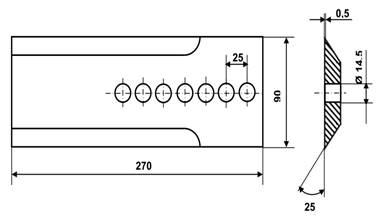

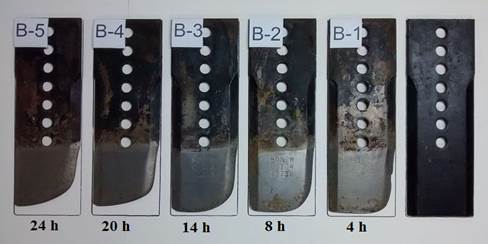

To carry out the experiment, five blades with an average nominal mass of 951.1g were selected, with geometrical characteristics and external dimensions as shown in Figure 1. The surface roughness is 6.3 μm, the hardness of the material of 58 ... 60 HRC and the identifying characteristics and chemical composition thereof are shown in Table 1. Once the tests have been started, the periods of 4, 8, 14, 20 and 24 hours of clean work (hours of work of the base cutter) are taken as time intervals for dismantling, cleaning and measuring the mass loss, measured with the machine electronic control system´s instruments. The weighing of the blades is done with a digital balance model HAW - 30K with an accuracy of ± 0.0001 kg (Figure 2).

TABLE 1 Identification characteristics and chemical composition of the BONEM base cutter-blades material.

| Code | Weight | Thickness | Material | Holes | |||

|---|---|---|---|---|---|---|---|

| 86902900BR | 0.951 kg | 6.00 mm | SAE 9260 | 7 | |||

| C | Mn | Si | Cr | Mo | Ni | S | P |

| 0.56 | 0.75 | 1.80 | No more | ||||

| 0.64 | 1.00 | 2.20 | ≤0.20 | ≤0.06 | ≤0.25 | ≤0.004 | ≤0.030 |

Results and Discussion

The results showed a red Ferrallitic soil with flat microrelief, with presence of silica particles and iron and aluminum oxides and hydroxides in its composition, which are highly abrasive. The variety of cut cane was the C-8751 of average length and diameters of the stems of 2.03 to 3.18 m and 30 mm, respectively, with a biological field yield of 122 t / ha.

These characteristics are predominant in the areas of the company and due to that the severe conditions of aggressiveness of the environment are confirmed as one of the causes of blades deterioration, which were also reported by Daquinta (2017) in studies of durability of these tools in harvesters, and Sánchez et al. (2010a) in evaluations of farm implements.

The average speed of the machine movement during cutting reached values of 4.6 km / h with a working speed of the base-cut set of 64.926 rad / s, magnitudes that are within the recommended values for this type of activity, which guaranteed the development of normal working conditions of the machine. The cutting height obtained was 85 mm, because during the harvest some stones were found that caused interruptions and breaks in the machines, so this height helped these and other obstacles in the soil, due to the agro-technical conditions of the fields, exerted the least influence on the flaw of the base-cutter blade.

The ambient temperature in the experimental zone was maintained between 25.7 and 31 oC, and the relative humidity reached average values of 75%, which allows affirming that the experiments were carried out in a work environment similar to that of previous years, so the climatic conditions did not influence beyond the normal in the development of the process.

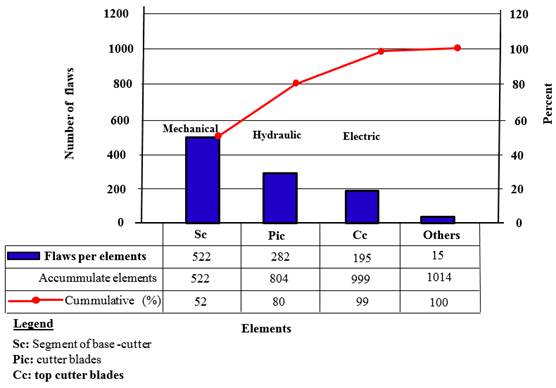

The flaw analysis revealed that the mechanical system is the one that fails the most, with 1014 faults as shown in Figure 3. Within it, the cutter segments are the ones with the highest total number of faults (999), with a higher incidence in the base-cutter blades and those of the chopper (804), which represent 80% of the total of failures in the system. The base-cutter blades are responsible for more than 50% of them (522) as represented in Figure 4, where the contribution of each element to the failures of the mechanical system appears. These results corroborate the criteria of Daquinta et al. (2014) and Daquinta (2017), who published similar results in research developed on KTP and CASE IH harvesting machines.

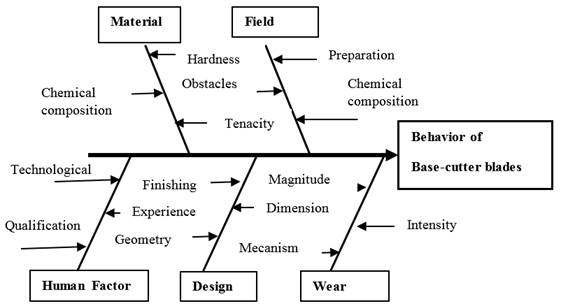

The representation of the causal elements that influence the functional behavior of the base-cutter blades is shown in Figure 5, which highlights the magnitude and intensity of the wear caused by contact with the plant mass and soil.

The statistical data of the field experiment are shown in Table 2. Figure 7 shows the representative curve of the wear dynamics, which reveals that the mass loss of the blades investigated in the first four hours shows a slight increase in its magnitude, whose value grows from 0 to 39.8g on average. This is because the highest peaks of the surface roughness are produced. That causes high pressures and deformations between the elements in contact and a high speed and intensity of the wear that reaches, in this case, 43.5% of permissible wear, which is in correspondence with the values recorded in this stage that can reach 30-50% (Álvarez, 2000).

The blades loss of mass obtained in the period between 4 and 20 hours of work, reached average values that vary from 39.8g to 61.4g. That shows a reduction in the magnitude of the wear and a smaller dispersion of the data obtained. This is because in this stage the real pressures decrease as the contact area between the tool and the vegetable mass to be cut increases. Here, the speed of wear becomes almost constant and it increases, but at a slower pace, which allows affirming that there is a stable work of the tool for a long time of its useful life with very little influence on the variation of its geometry (Figure 6) and properties, identifying characteristics of the normal wear period.

After 20 hours of work, the average mass loss of the blades initiates a prolonged increase in its magnitude and dispersion of the data, which is due to the beginning of the catastrophic wear period. In this stage the magnitude of the wear is such that complementary dynamic loads are generated in the operation of the tribological par, which represents an increase in temperature, noise level, vibrations and, in this specific case, the bad quality in the cut, causing damage to the cane stems and exerting a direct influence on crop losses. This behavior has been explained by Toledo et al. (2013; Manhães et al. (2014); Mathanker et al. (2015); Tahsin et al. (2016) y Momin et al. (2017) in evaluations of the influence of blade wear on damage to cut stems.

TABLE 2 Statistical data of the wear test.

| Simple | Initial Weight (g) | Mass Loss (g) (4 hours) | Mass Loss (g) (8 hours) | Mass Loss (g) (14 hours) | Mass Loss (g) (20 hours) | Mass Loss (g) (24 hours) |

|---|---|---|---|---|---|---|

| A | 951.0 | 34 | 48 | 50.5 | 58 | 76.5 |

| B | 952.5 | 45 | 49.5 | 51 | 62 | 102 |

| C | 950.4 | 37.5 | 49 | 54 | 65.5 | 111.5 |

| D | 950.5 | 47 | 49 | 51 | 62.5 | 100.5 |

| E | 951.1 | 35.5 | 50.5 | 51.5 | 59 | 67.5 |

The magnitude of wear in the 24-hour period causes the loss of the geometry of one of the edges of the tool, and therefore, it is estimated that in another similar period of time the blades will lose their ability to work. These results allow affirming that the physical and mechanical properties of the cut vegetable mass, the soil and the surrounding medium have an effect on the wear of these tools, directly influencing their behavior and useful life.

The results of the statistical model implemented and the estimation of the parameters are observed in Table 3, where a value of the coefficient of determination R2 = 0.874 is distinguished, which represents the adjustment of the data in relation to the polynomial regression curve of third grade developed by the model. This curve allows predicting the behavior of the base-cutter blades for any time interval, which favors the analysis and estimation of their working capacity. This type of curve has been reported by Mellado (2005) and Sánchez et al. (2010b) under other experimental conditions in tools for earthmoving, rock drilling and soil tillage machinery, but which respond from the mathematical point of view, to the same behavior model. However, no research is reported in the literature that describes the behavior of the wear dynamics in the base-cutter blades of sugarcane harvesters.

Conclusions

The base-cutter blades were responsible for more than 50% of the failures of the mechanical system in the sugar cane harvesters CASE IH-7000, mainly due to the accelerated wear of the cutting edge.

The average mass loss of the base-cutter blades under study took values ranging from 0 to 91.5g for a clean working time of 24 h, which causes the loss of the geometry of one of the cutting edges. Because of that it is estimated that for a period of 48 h, these tools will lose their total capacity of work.