INTRODUCTION

The seed is the main reproductive organ of the great majority of terrestrial and aquatic superior plants. It carries out a fundamental function in the renovation, plant populations’ persistence and dispersion, regeneration of the forests and ecological succession. By means of agricultural production, seeds are essential for human beings, since they constitute men’s main food direct or indirectly, and they also serve as food for domestic animals. Seeds can be stored alive for long periods, making sure this way, the preservation of species and varieties of valuable plants (Doria, 2010).

Among these valuable plants, forage plants can be cited for their great contribution to animal and industrial production, but these, in turn, are limited due to diverse factors. One of the factors that limit the development of grasses under tropical conditions is the availability of seeds. It has constantly been recognized, the necessity of developing a policy that impels the production and benefit of seeds and creates the bases for an ample commercialization with suitable quality and enough to satisfy the necessities of agricultural companies. The results found up to the present moment, regarding the production of seeds of grasses in the developing countries, indicate the necessity to increase the knowledge about the diverse factors that intervene in it, in order to obtain bigger yields of seeds of quality (Pérez et al., 1988).

One of the main causes of losses in the production of the nurseries is the excess of moisture content of the seeds after the harvest process, because of that it is important to achieve the appropriate moisture content of the seeds after harvesting. Most of the seeds reach their physiologic maturity with moisture contents that vary from 35 to 45%. Their conservation is safe with the condition that these percentages descend to values from 10 to 12%.

On the other hand, the knowledge of the physical properties is of supreme importance to design and to optimize the equipment required in the processing steps of the agricultural products, as it has been stated by diverse authors like: Stroshine & Hamann (1993); Ospina (2001) and Cetin (2007). In turn, studies carried out by Andrejko and Grochowicz (2007), Dziki (2008), Kilickan and Guner (2008) and Altuntas and Yildiz (2017), in other seeds, demonstrate that the physical properties are influenced by the moisture content.

Considering the aforementioned, the solar drying plays an important part in the post-harvest handling of seeds, since it allows the reduction of their moisture content without influencing negatively in their properties.

Solar drying is a highly profitable branch in the exploitation of renewable sources of energy, characterized by its high energy, economic, social and ecological potential, compared with the other energy sources used to dry. The increment of use of renewable sources of energy is a key aspect in the development strategy for tropical countries, as Cuba, and their high potentials for energy saving and for the substitution of fossil fuels are recognized universally, with the consequential decreasing of CO2 emissions, nitrogen oxides and sulphur, products of the combustion that generate a negative impact in the economy and the environment (Bergues et al., 2010).

Solar drying in Cuba is a young and not very well-known branch. Tendencies regarding solar drying in Cuba have strengthened in the last two decades, based fundamentally on the use of local materials for the construction of dryers and the simplification of some designs (Bergues et al., 2008).

METHODS

THEORETICAL AND METHODOLOGICAL FOUNDATIONS

Theoretical-Methodological Foundations for the Determination of Physical Properties of Forage Seeds

The knowledge of physical properties of grains and seeds constitutes a fundamental information in engineering to adapt and to operate machines, to design and build storage structures and to establish appropriate systems of transport. On the other hand, it is a fundamental parameter to design packing, for quality analysis and for process control. Among these properties some can be mention like size, density, mass, moisture content and loss of weight or mass variation.

Size (shape and size): This property allows to describe any product and it influences considerably in the movement of the liquid inside the product during drying process. Criteria of roundness, sphericity and similarity to certain geometric forms are used to determine the shape and size of a seed, therefore different mathematical expressions can be used, which are based on the three main orthogonal dimensions: longitudinal (bigger axis), width (medium axis) and thickness (smaller axis). The approaches to determine the size are defined by the mean geometric diameter (Dg) and the mean arithmetic diameter (Da), which are determined by using the following expressions:

Sphericity is also established to determine the form of a biological material, with the following expression:

Density: Density is defined as the relationship among mass of the product and the volume occupied by it. In grains, two types of density are distinguished (apparent density that is the density of the individual grain, and bulk density). Bulk density is the relationship between the weight and the total volume of the mass of the product, including the interstitial spaces that materials let among them, this is also denominated volumetric density. Apparent density is an important factor in the analysis of transfers of mass and heat through grains or seeds, in the control of quality, in the evaluation, calculation and design of systems of transport, cleaning and classification.

Mass: Quantity of matter that possesses a body, in the case of the agricultural products between a 10 and 70% of their mass corresponds to the content of water varying with their characteristics.

Moisture Content: It is the quantity of water that a product possesses. It constitutes one of the fundamental properties that guarantees the stability and conservation of agricultural products, either dehydrated or dried. Its determination in the seeds, regarding the duration of the drying processes, is carried out in an experimental way by using a certain drying installation or a portable moisture meter.

Moisture content is an index of quality of the product that can be expressed in humidity base or in dry base, as it is shown in the expression (4).

The level of moisture content of the seeds is measured by the period of one hour to observe the change in their moisture content, this is denominated rate of moisture content reduction per hour, which can be determined with the expression:

Where:

Ma |

- Moisture content after drying, % |

Mi |

- Moisture content before drying, % |

to |

- Operation time, h |

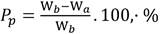

Loss of Weight or Mass Variation: It is the difference of grain or seed mass before drying compared to it after being treated thermally. It increases during the drying process and influences directly in the time of the drying process, being determined by means of the expression: (Thompson et al., 1985).

Where:

Pp |

- Loss of weight, % |

Wb |

- Initial mass before drying, kg |

Wa |

- Mass of the product after drying process, kg |

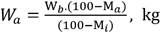

The mass of product after being dried can be determined by using a scale, if there were not this mensuration instrument, it can be determined with the following expression:

Theoretical-Methodological Foundations for Modeling the Kinetics of Fluid Movement inside the Dryer and the Seed Layer

All solid and semi-solid materials contain interstitial spaces (pores) of the size of ordinary molecules that can be penetrated by a fluid. The distinction between a porous material and a non-porous solid is not still clear. However, if only permeability is considered as condition to establish a classification, a porous material will have a specific permeability, and its value will only be determined by the geometry of the pore, independently of the properties of the fluid.

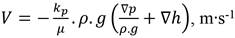

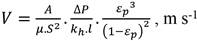

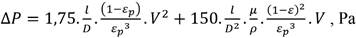

There are different models that describe the dynamics of the flow of an incompressible fluid appropriately through a porous medium. Among them, literature refers the general equation of Darcy in presence of gravity (8; 9), the equation of Kozenin-Carman (11) and the equation of Ergun (12). The first one is an empiric result for saturated porous media and it is stated that the speed of Darcy (V) is a lineal function of the pressure gradient in absence of gravity.

Darcy’s equation in piezometric terms can be considered in the following expression:

where:

v i |

- interstitial speed through the pores, m/s |

Ɛ p |

- porosity |

µ |

- dynamic viscosity of the fluid, Pa s |

k p |

- tensor of intrinsic permeability of the medium, m2 |

∇p |

- gradient of pressure, Pa∙m-1 |

ρ |

- density of the fluid, kg∙m-3 |

g |

- acceleration of the gravity, m∙s-2 |

∇h |

- bench mark gradient in height with regard to a reference level, mm-1 |

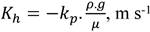

The tensor of hydraulic conductivity ( K h ) is defined as:

Equation 11 has a focus or approximation much nearer to the physical phenomenon than equation of Darcy, when keeping in mind, not only the gradient of pressure and the permeability, but also the porosity of the medium. The equation of Ergun (12) has a more general focus than the equation 11, in which, it is kept in mind, the effect of inertial forces (first term) for numbers of Reynolds superior to 1 000 and of the viscous forces (second term) for numbers of Reynolds inferior to 10.

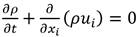

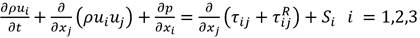

The kinetics of movement of the fluid (air), by the interior of the dryer and the layer of seeds (porous medium), can be modelled by means of the computer application SolidWorks of mechanical design. This tool uses the graphic user interface of Microsoft Windows. This application facilitates to carry out a quick outline and the projection of models and detailed drawings. The computer package SolidWorks contains a group of programs as the software Flow Simulation, where the behaviour of the fluid’s characteristics is obtained inside a modelling system for different limiting conditions consisting in the inclusion of stabilizing meshes and elements of fluid attenuation. The Flow Simulation software has been developed among other applications, to simulate, to study and to predict the behaviour of a fluid under different conditions of transport of mass and energy of the fluid, as well as processes of heat transference between it and a solid. The software uses the equations of Favre-Averaged and Navier-Stokes (expressions 13, 14 and 15) for the conservation of mass and energy. Likewise, for the transport of the turbulent kinetic energy and of their dissipation rate, the pattern k is used k-Ɛ (Matsson, 2013).

Where:

u |

- speed of the fluid, m/s |

ρ |

- density of the fluid, kg/m3 |

Si |

- it represents the external force distributed by unit of mass due to the hydraulic resistance of a porous medium, N |

H |

- it represents the sum of the thermal enthalpy of the fluid and its kinetic energy, J |

Q H |

- it represents the external sources of heat, J |

Ʈij |

- tensor of the viscous tangential efforts for a Newtonian fluid, N |

Ʈij R |

- tensor of the tangential efforts of Reynolds, N |

Ɛ |

- rate of dissipation of turbulent kinetic energy |

q i |

- flow of heat for diffusion, W. |

The software uses a method to determine the permeability or vector of resistance of the porous medium (k p ) in function of fall of pressure, flow of mass, speed and dimensions of the porous medium, equation (16):

Data related to fall of pressure in function of the flow of mass  are specified, starting from the results obtained experimentally, while the traverse section (S) and the length of the porous medium (L) in the direction of the speed, remain constant.

are specified, starting from the results obtained experimentally, while the traverse section (S) and the length of the porous medium (L) in the direction of the speed, remain constant.

The project is created to develop the simulation with the use of Computer Flows Dynamic (CFD), in Simulation of Fluid, where the following data are defined:

System of units: The International System of Units is declared;

Analysis type: Intern, excluding the cavities without conditions of flow;

Fluid: Air, selecting the automatic option of behaviour, either laminar or turbulent, as characteristics of the fluid;

Wall conditions: Adiabatic;

Initial conditions: thermodynamic parameters of pressure and temperature.

Resolution of the results and the geometry: it is declared as an automatic configuration, a level similar to 5 for the geometry of computational mesh.

Once the project is generated, the entrance data (articles of the project tree), are defined to develop the simulations which are described:

1) The icon Computational Domain is used to modify the dimensions of the volume that it is being analyzed and it allows visualizing the limits of the computational domain;

2) The icon Boundary Conditions allows establishing the parameters to the fluid, in the entrance or exit of the computational domain:

Pressure;

Flow of mass;

Flow of volume;

Speed;

Model that characterizes the fluid regime (laminar or turbulent);

Conditions of wall of the solid elements that are in contact with the fluid.

3) The icon Porous Medium allows establishing which of the components of the pattern is treated as such, starting from the information contained in the database of engineering of the software;

4) The icon Engineering Goals allows defining what parameters are of interest in order to reduce the time of calculation when reaching the convergence of the solution and to influence in the stop criterion.

5) The icon Local Meshes allows diminishing the size of the computational domain in a specific region of the domain for the sake of reaching bigger precision of the results in this region.

The phenomenon anisotropic thermal conductivity in solid media is described by means of the following equation:

Where:

e |

|

c |

- it is the specific heat, J/K.kg |

QH |

- it is the liberation (or absorption) specific of heat per unit of volume, W/m3 |

λ i |

- they are the values characteristic of the tensor of thermal conductivity, W/mK. It is supposed that the tensor of thermal conductivity is diagonal in the considered system of coordinates. For the adiabatic isotropic medium: |

Besides the conduction of heat in solids, Flow Simulation System is able to calculate the transference of radiation heat among solids. In the simulation of flow, two models of radiation are used, Discreet Transfer and Orderly Discreet Transfer, each of them has its own limitations and benefits.

RESULTS AND DISCUSSION

Determination of Main Physical Properties of Forage Seeds

To determine the main physical properties of forage seeds, only those, whose information justifies the dimensions of some parts of the drying system, were considered. According to the size of the varieties of seed to use, the dimensions of the sieves to utilize, was selected. The sieves of the design were selected for each variety with (-0.5 mm) than the size of the smallest orthogonal dimension of the seeds. To determine the orthogonal dimensions, a vernier was used, with a margin of error of 0.01 mm.

TABLE 1 Orthogonal dimensions of some forage seeds

| Average Orthogonals Dimensions, mm | Sorghum halepense | Stizolobium deergeanum | Moringa oleifera | Centrosema pubescens | Clitoria blue |

|---|---|---|---|---|---|

| Length | 5.11 | 14.11 | 11.49 | 6.43 | 6.41 |

| Width | 3.23 | 16.27 | 10 | 5.67 | 4.75 |

| Thickness | 2.66 | 6.63 | 10.94 | 4.85 | 2.45 |

The results of the average orthogonal dimensions of the seeds chosen to select the meshes for the drying system design are represented in Table 1. As it is possible to appreciate, the smallest orthogonal dimension was obtained in seeds of Clitoria blue with 2.45 mm of thickness. Similar result was observed in seeds of Sorghum halepense with 2.66 mm of thickness and the biggest dimension was obtained in the seeds of Stizolobium deergeanum with values approximate in large of 14.11 mm, continued by Moringa oleifera seeds and Centrosema pubescens with length values of 11.49 and 6.43 mm, respectively.

For the experimental investigation and the design of the solar drying prototype for forage seeds, it was considered the seed of Sorghum halepense. Its bulk density was determined, by using a test tube of 100 mL, to determine the mass that occupies a volume of 30 mL. From this volume, a mass of 26.98 g was obtained and it was determined by placing the product in an analytic scale with an error margin of 0.0001 g of minimum reading. Considering that 1 mL = 1 cm3, a bulk density of 899 kg/m3 was obtained. This value is necessary for knowing that, the seeds to dry off, would occupy a volume of 0.20 m3. That also allows knowing the loads the system will be subjected to and predict if the structure resists them. Besides, it facilitates to know the volume of air required to remove the quantity of water contained in the sample of seeds to dry off (humidity of the seeds).

Modelling of the Fluid Movement Kinetics inside of the Dryer and of the Layer of Seeds

Starting from the determination of the physical properties, the mass of seeds of Sorghum halepense considered for the design and modelling of the drying installation is of 180 kg, taking a rate of moisture reduction of 0.60%/h, in a such way that the drying time does not go above 10h, which is due to the characteristic of the solar drying of forage seeds.

Once the optimum location of the solar collector and the characteristics the ventilation system in the conceived drying installation were established, the kinetic modelling of fluid movement inside the dryer and of the layer of seeds were performed. Two study variants were determined: the first one, for forced convection without porous medium (without considering the layer of seeds) and the second one, for forced convection with porous medium (considering the layer of seeds). In each variant, the behaviour of the temperature, the relative pressure and the fluid speed were defined.

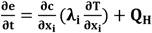

In Figure 1, the behaviour of the fluid temperature (air), for each variant analysed in the design, is shown.

FIGURE 1 Behaviour of the temperature in the dryer conceived with forced convection: a) with porous medium (considering the layer of seeds), b) without porous medium (without considering the layer of seeds).

As it is observed in Figure 1, the temperature of the fluid, in both variants analysed, increased in the region of the solar collector regarding the ambient temperature. In the specific case of the variant that considers the porous medium, an increment of 3 0C is achieved in the region of the collector and, in the region of the drying chamber, a descent is experienced in the temperature of the fluid of 2 0C. The same happens in the variant that does not consider the porous medium, however, in this variant, an increment of 20C is achieved in the region of the collector and same value to the one obtained in the variant that considers the porous medium is achieved in the region of the drying chamber.

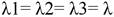

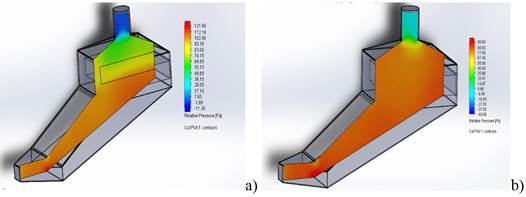

In Figure 2, the behaviour of the relative pressure, in each variant analysed in the design, is shown.

FIGURE 2 Behaviour of the relative pressure in the dryer conceived with forced convection: a) with porous medium (considering the layer of seeds), b) without porous medium (without considering the layer of seeds).

When analysing the behaviour of the relative pressure, shown before in the figure represented, it is observed that in the specific case of the variant that considers the porous medium, the maximum pressures are reached in the region of the collector, specifically, at the exit of the fan with a value of 121.66 Pa and the minimum pressures are reached in the region of the drying chamber, specifically, in the conduit of exit of the humid air (chimney), with a value of -11.36 Pa. That evidenced a pressure falling of 110.3 Pa. However, in the variant that does not consider the porous medium, the maximum pressures are reached equally in the region of the collector, specifically at the exit of the fan with value of 99 Pa and the minimum pressures are reached in the region of the drying chamber, specifically, in the conduit of exit of the humid air (chimney), with a value of -16.65 Pa. That evidenced a pressure falling of 82.35 Pa.

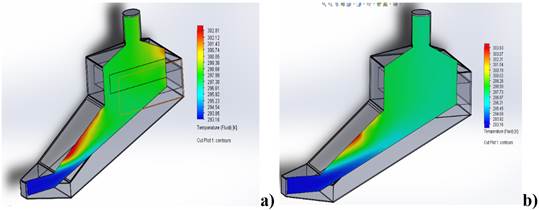

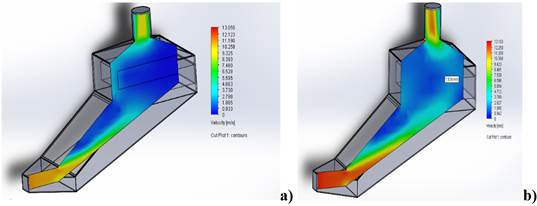

In Figure 3 is showed the behaviour of the speed of the fluid (air) in each one of the variants analysed in the design.

FIGURE 3 Behaviour of the fluid speed (air) in the dryer conceived with forced convection: a) with porous medium (considering the layer of seeds), b) without forced convection for porous medium (without considering the layer of seeds).

When being observed the behaviour of the fluid speed (air), represented in Figure 3, it is observed that in the specific case of the variant that considers the porous medium, the maximum speed of the fluid is reached in the region of the collector, specifically, at the exit of the fan with a value 11.19 m/s, which is due to the increment of the fluid kinetic energy. And the minimum fluid speed is reached in the region of the drying chamber, specifically in the inferior area (base of the layer of seeds to dry off), where a value of 0.93 m/s is reached and evidenced that a variation of speed of 10.26 m/s is experienced. On the other hand, the fluid speed increased, once it crosses the layer of seeds, reaching a value of 10.26 m/s, which is equivalent to the variation of the speed of the fluid experienced inside the drying installation.

In the case of the variant that does not consider the porous medium, the maximum fluid speed is reached equally in the region of the collector, specifically, at the exit of the fan with value of 13.19 m/s and the minimum speed of the fluid is reached in the region of the drying chamber, specifically, in the inferior area (base of the layer of seeds to be drought off), with a value of 1.00 m/s, which evidenced that a variation of speed of 12.19 m/s is experienced. On the other hand, the fluid speed increased, once it crosses the drying chamber, reaching a value of 12.20 m/s, being this a very next value to the variation of the fluid speed experienced inside the drying installation.

Summarizing, both, in the variant that considers the porous medium and in the variant that does not consider the porous medium, an increment of the temperature is experienced inside the drying installation; but it is valid to point out, that this increment does not exceed the 3 oC and it is inferior to values obtained by several researchers like Bergues et al. (2008 & 2010) and Morejón et al. (2014), who developed drying machines similar to the design proposed in this work and obtained increments of temperature that oscillated between 5 oC and 10 oC. This result can be influenced by the selection of the materials considered in the design, specifically, aluminium, because this material has a high thermal conductivity that prevents to retain the heat inside the installation.

On the other hand, for both analysed variants, a high fall of pressure is appreciated that behaves directly proportional to the fluid speed in the inferior part of the drying chamber. However, when the fluid (humid air) is expelled to the environment through the chimney located in the superior part of the drying chamber, an increment of the speed is experienced, which evidenced the principle of Bernoulli, since it demonstrates that the quicker the ambient wind blows on the mouth of the chimney, the lower the pressure will be and higher the difference of pressure between the base (superior part of the drying chamber) and the mouth of the chimney will be, and consequently, the humid air is extracted better.

Results of the Energy Transfer and Mass in the Conceived Drying Installation

The flows of heat that respond to the three principles of heat transfer were determined by using the computer system Termotransf by Morejón et al. (2015). These results are of great importance for this type of system, which should achieve temperatures superior to that of the environment to carry out a process of efficient drying, without damaging the physiologic quality of the seeds. The results of the flows of heat were determined separately for the drying chamber and for the collector and they are represented in Table 2.

As it is appreciated in Table 2, considering an external or ambient temperature of 27 oC, an average internal temperature reached of 29 oC, a coefficient of thermal conductivity for aluminium, glass and seeds of 209.3; 0,5 and 0.4 W/m.K, respectively, a flow of heat was obtained by thermal conductivity of 37.65 W. It demonstrates that, the energy impacting on the materials used in the dryer, is absorbed and this facilitates the increment of temperature inside the machine. The flow of heat by thermal radiation was determined through the Stefan-Boltzmann Law, and considering that the incident temperature in the cover (sheet of glass type nonex) is of 27 oC, it was obtained that the flow of heat by radiation in the collector is of 436.30 W. When analysing the flow of heat by radiation in the drying chamber, which was conceived to be made of aluminium, a flow of heat of 665,94 W is obtained. In this way it is evidenced that the incident solar energy on the materials conceived for the construction of the dryer is absorbed in all the regions of it. For the analysis of the heat flow by thermal convection, a coefficient of heat transference of 10 W/m2K was considered which responds to a forced convection of air. That is in correspondence with the design proposed which uses a fan to increase the kinetic energy of the air. By means of the plans conceived in the design, the areas for circulating hot and humid air, both, in the collector and in the drying chamber, are determined and, with the values of the temperatures of the surrounding media and the fluid in the analysed regions, the flow of total heat was obtained for convection of 7 W.

From these results, the flow of total heat of the conceived drying installation was determined, which ascends to 1146.89 W (1.146 kW) and it demonstrates that the conceived design can work as a dryer. Starting from these values and from the value of the average solar radiation incident on Cuba that is 5 kW/m2, the thermal efficiency of the prototype was determined as 9.5%. This value means the percent of solar energy that the system takes advantage. It is significant that the obtained efficiency is inferior to the values of efficiency obtained by Bergues et al. (2008 & 2010), who investigated and developed solar dryers similar to the one proposed in the present investigation.

TABLE 2 Results of the heat flow obtained on the component parts of the dryer system proposed

| Materials | HEAT FLOW, W | ||||||

|---|---|---|---|---|---|---|---|

| Conduction | Radiation | Convection | Total Heat | Area, m2 | Total Heat/ Area, W/m2 | Thermical Efficiency, % | |

| Drying Chamber | 5.99 | 665.94 | 4.2 | 676.13 | 1.45 | 477.87 | 9.5 |

| Collector | 31.66 | 436.30 | 2.8 | 470.76 | 0.95 | ||

| Total | 37.65 | 1102.24 | 7.0 | 1146.89 | 2.4 | ||

CONCLUSIONS

The outlined theoretical foundations facilitated to carry out the modelling and establishment of the design parameters for a solar dryer of forage seeds.

The thermal modelling and kinetics of the conceived design were carried out with the utilization of the computer systems SolidWorks and Termotransf, considering the porous medium (layer of seeds to dry) and evidencing an increment of the temperature and a fall of pressure, inside of the proposed installation.

By means of modelling the solar drying process and taking into account a rate of moisture reduction of 0.60%/h, it is considered that 10 h are required for processing 180 kg of seeds of Sorghum halepense.

The flow of total heat in the solar dryer of forage seeds conceived, ascends to 1.146 kW and reaches a thermal efficiency of 9.5% which demonstrates that, even when the design possesses a low efficiency, it works like a drying installation.

For the modelling and design of the proposed solar dryer, aluminium sheets were selected for the walls of the structure and glass for the collector, for what it is recommended to use another material with a coefficient of thermal conductivity lower than that of the aluminium, in such way that facilitates to elevate the efficiency of the installation.