INTRODUCTION

Centrifugal pumps are hydraulic machines that transform a mechanical work into another of hydraulic type according to Cherkasski (1986), Ramos (1994) and Fernández (2017), which are used in most industrial processes for the transfer of fluid from one place to another. Consequently, their use has increased according to Pérez (2004) and Reyes and Izquierdo (2007), from small pumps for domestic purposes to large machines for industries and supplying cities (Pérez, 2004).

One of the industries that uses centrifugal pumps in Cuba is the sugar industry according (Moreno et al. (2018) and the plants for the production of Cuban Silage Feed (CSF) belonging to this sector are not the exception. Eleven unique plants of their type with a capacity of 45 t / 8 h are the result of several studies that led to their extension throughout the country (Lezcano et al., 2017). Overexploitation of pumps in industries and their abuse can shorten their useful life.

This new liquid food is made from the mixture of by-products and wastes from the sugar industry (honey B, thermolised Saccharomyces cerevisiae yeast cream, concentrated vinasse) and agricultural surpluses according to Lezcano et al. (2016). It has raw materials (yeast cream and vinasse) that sediment and generate a final product with solids in suspension, which also deposit in the bottom as a sediment. This technology was developed by ICA and received the category of patent through resolution 2013-0122 (Lezcano et al., 2016).

Sedimentation is the operation that consists of separating from a suspension, a clear liquid supernatant on the surface and a sludge that is deposited on the bottom that has a high concentration of solid matters. The gravitational field acts as a driving force in this operation (Smith and Harriot, 2002). For the selection of the type of pump to be used for the recirculation and impulsion of liquids in industrial processes, it is necessary to know the properties of these and see how the solids present in them behave and at what speed they settle.

This work was developed in "Héctor Molina" plant, San Nicolás de Bari, Municipality of Mayabeque, Cuba. It aims to determine how often centrifugal pumps have to work for industrial silage production to maintain a stable chemical composition according to the parameters established in the process of obtaining the CSF on an industrial scale and analyze the behavior of the variable sedimentation vs. time with statistical criteria.

METHODS

A sedimentation velocity study was carried out in order to know the variation over time of the phases in which the liquid raw materials are divided (concentrated vinasse, Saccharomyces cerevisiae yeast cream thermolised) and the CSF. Those are the aspects to be taken into account to propose the frequency with which the liquid raw materials should be recirculated to maintain a stable chemical composition and the CSF for the non-sedimentation in the silos.

Methodology to determine sedimentation rate

To determine the sedimentation rate of the solids, three experiments, different according to the products to be studied, were carried out.

Experiment 1: Determine the sedimentation rate of cream of thermolised Saccharomyces cerevisiae yeast.

Experiment 2: Determine the sedimentation rate of the concentrated vinasse.

Experiment 3: Determine the sedimentation rate of the CSF.

Sedimentation tests were performed in the Institute of Animal Science, IAS laboratory by the method of Coe (1916), where the sedimentation velocity of the solids is obtained. From the experimental data, slope values at the origin were determined, - (dh / dt), which coincide with the sedimentation velocities (v) and the sedimentation theory according to Kynch (1952), who considers sedimentation velocity (v) only depends on the concentration. Each sedimentation test (corresponding to each experiment) was carried out with 10 graduated glass test tubes of 250 mL capacity, which have a graduated height scale. The time was measured with a digital chronometer: Oregon Scientific Mark, Model SL210, from zero to 24 h, precision 0.01s. The test tube was illuminated at the back with a flexible lamp, to better observe the advance of the interface.

The product was introduced into the graduated test tubes, up to height (h0), shaken and the test tube were deposited on a horizontal surface (Figure 1), at which time the digital chronometer was started. Measurements of the descendant interface height were taken at intervals of 10, 20, 30 min during the first 5 h and every 1, 2, 3, 4, 6, 12 and 24 h after the fifth hour, until the end of the study. The behavior of the height of the interfaces in the test tubes (TT) in each time interval and the initial and final parameters (h0, hi) in time for each test tube were determined, which determines the sedimentation rate for each test.

Statistical - Mathematical Analysis

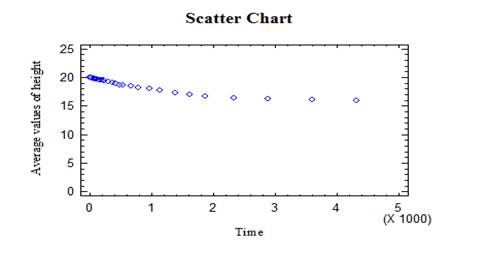

To describe the relationship between CSF sedimentation and time, first and second order simple linear regression models were tested according to what was suggested by the scatter chart between these variables (Figure 2). The selection of the best fit model was based on the goodness-of-fit criteria provided by Guerra et al. (2003), which were: coefficient of determination R 2 and R 2 adjusted for the degrees of freedom, significance of the parameters and the model and the residual mean square (RMS). The analysis was done with the STATGRAPHICS Centurion XVI software (Statgraphics Centurion, 2012).

RESULTS AND DISCUSSION

Experiment 1: Results of sedimentation rate of cream of thermolised Saccharomyces cerevisiae yeast.

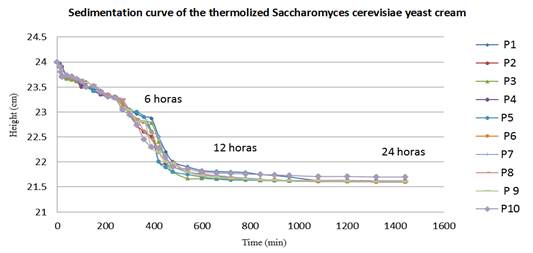

In the sedimentation test, the height of the interfaces in time and the sedimentation rate is obtained. It was observed that after 360 min (6 h) the product began to separate in two phases and at 540 min (9 h) there is a concentration of the particles in the bottom of the test tubes. The suspended particles developed a sedimentation rate of 2.76 E-7 m/s. It is observed (Figure 3) the behavior of each test tube (P1, P2, ..., P10), that according to the results, the thermolised Saccharomyces cerevisiae yeast cream has to be recirculated every 12h to be used in the agro-industrial process.

Experiment 2: Results of the sedimentation velocity of the concentrated vinasse

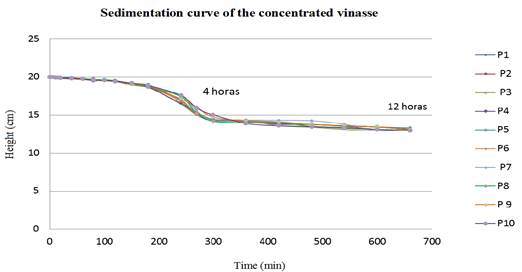

In the sedimentation test, the height of interfaces is obtained in time and the speed at which it sediments. It was observed that after 240 min (4 h) the product began to separate in two phases and at 300 min (5 h) there was a higher concentration of the particles in the bottom of the test tubes. In the concentrated vinasse the particles in suspension became sediment at 1.58 E-6 m/s.

It is observed (Figure 4) how the concentrated vinasse behaved for each test tube and according to the results, the concentrated vinasse has to be recirculated every 4 h, to be used in the agro-industrial process.

Experiment 3: Results of CSF sedimentation rate

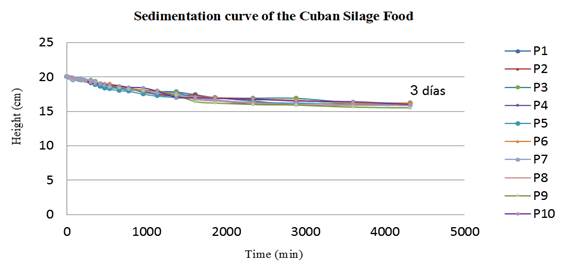

In the sedimentation test of the CSF, the height of the interfaces in time and the speed at which the CSF sediments are obtained. It was observed that starting at 58 h the product began to separate into phases. Sweet potato particles remained on the surface of the test tubes, which, when absorbing the liquids of the mixture, increased their weight, as the liquids had a higher density than the sweet potato. Sweet potato particles began to compact at the third day of slow dropping (1.55 E-7 m/s).

It is observed (Figure 5) the behavior of the CSF for each of the test tubes and it is considered that it has to be recirculated, to avoid the compaction in the silos, action that improves the agro-industrial process.

It was demonstrated that the products studied must be recirculated and concentrated vinasse developed greater sedimentation speed (1.58 E-6 m/s) with respect to the thermolised Saccharomyces cerevisiae yeast cream (2.76 E-07 m/s) and the SF (1.55 E-07 m/s).

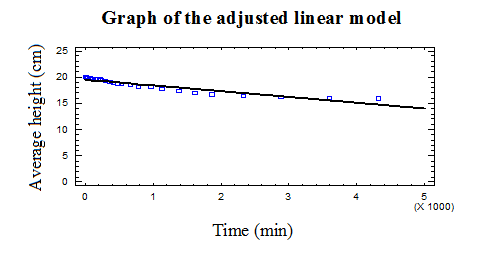

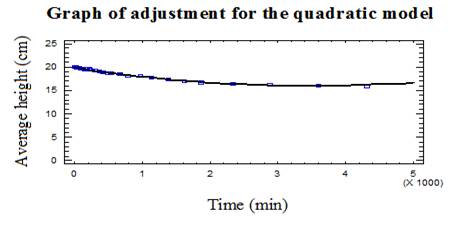

Table 1 shows the results obtained for the goodness-of-fit criteria of the adjusted models. It is observed that the two models are statistically significant as well as their corresponding parameters at a significance level of 0.05, given by the corresponding values of p. The values adjusted of R 2 for the first and second order linear model were 87.65% and 99.5%, respectively, and it was higher in the quadratic model. On the contrary, the value of the RMS decreased from the linear model of first order to the quadratic model. Figures 6 and 7 show the graphs for the linear and quadratic models adjusted, respectively.

TABLE 1 Results of the adjustments of the simple linear regression models for the sedimentation of the CSF

| Aspects/Models | Linear first order | Linear second order |

|---|---|---|

| Expression |

|

|

| Estimators of β(b) |

|

|

| Significance of the parameters |

|

|

| Significance of the model | 0,0000 | 0,0000 |

|

|

88,13 | 99,53 |

|

|

87,65 | 99,5 |

| RMS | 0,222041 | 0,00901737 |

With respect to compliance with the assumptions of experimental errors for the two adjusted models (normality, non-correlation and homoscedasticity), the residuals were standardized to identify them with the normal distribution with mean 0 and variance 1, which includes compliance with the assumption of homogeneous variance, being this 1. In Table 2, the fulfillment of these assumptions is shown. It is observed that the two adjusted models have the same behavior in this regard.

TABLE 2 Compliance with the assumptions of the errors in the adjusted models

| Models | Normality | Non-correlation | Homocedasticity |

|---|---|---|---|

| Linear first order | It is fulfilled | It is not fulfilled | It is fulfilled |

| Linear second order | It is fulfilled | It is not fulfilled | It is fulfilled |

According to the above criteria, the model that best describes the sedimentation of the CSF is the model of second order of expression:

Based on the criterion of the first derivative for the expression of the quadratic model, it is estimated that the minimum value of the sedimentation of the CSF is of 15.91 cm at approximately 3490 minutes (58 h).

CONCLUSIONS

The centrifugal pump must recirculate the cream of thermolised Saccharomyces cerevisiae yeast and the concentrated vinasse every 12 h and 4 h, respectively, so that they can be used with a stable chemical composition in the agro-industrial process.

The centrifugal pump must recirculate the CSF every 58 h to avoid compaction in the silos, an action that improves the dispatch process and the delivery of a homogeneous product.

Maintaining the stability of raw materials and complying with the technological process proposed on an industrial scale to produce CSF, allows obtaining a behavior similar to that studied and in correspondence with the quadratic model.

texto em

texto em