INTRODUCTION

The agricultural sector of Ecuador is distinguished by the duplicity productive, on one side the production units of more than 100 ha, with technical, technological and economic sufficiency, oriented to supply external markets and by the other side the UPA (Agricultural Productive Units), small extensions between one and five hectares, limited in technology, productivity and even credit lines. To respond to the demands of small farmers and contribute to the process of modernization of the rural sector, since 2014 in the province of Manabi, the program "Community Agricultural Mechanization" is being developed. The first stage of the program consisted of the delivery to the agricultural associations of 1 942 power tractors and 94 agricultural tractors, YTO-704, with the main implements, acquired in 2009 by the National Development Bank (BNF), currently Ban Ecuador. It was done to technify the work on the land, reduce labor costs and increase the production of small and medium producers in the province (Cevallos & Shkiliova, 2016). The mechanization of small plots is not very profitable and it is very difficult with the use of tractors or practically impossible, if there are other factors, such as abrupt slopes, stoniness or the low bearing capacity of soils due to their high water content (flood), or requires the use of highly specialized machinery. In these situations the motor cultivators are the only motorized equipment that can act (Márquez, 2010).

The tiller (also known as a two-wheel tractor, single-axle tractor, walking tractor) with different implements can do many types of agricultural work, such as tillage, harvest, planting and transportation. At present, there is a large number of designs of power tillers around the world, to serve the different markets. Among them, the Chinese machinery is of relatively low cost, which is widely used not only in China, but also by small African farmers and Latin Americans (Chew et al., 2013). In Ecuador, the Chinese YTO DF-15L traction machines provided by the MAGAP prevail. The distribution was made throughout the country, in different provinces, to organizations and associations previously qualified by the MAGAP, even theoretical and practical training was given to the beneficiaries on the proper use of the machinery. In Costa region, 777 motor cultivators were handed over, representing 40% of the total, 140 of them were delivered in Manabí Province (MAGAP, 2014). According to INEC (2000), the province of Manabí, at the beginning of the 20th century had 74 676 UPA, which used 1 583 661 ha to produce. Specifically for the transient crop of watermelon, 733 UPA occupied 969 ha for planting. Jipijapa County had 8.491 UPA, with availability of 90 129 ha for production, 60 of them dedicated to the cultivation of watermelon in 63 ha. Watermelon (Citrullus lanatus), native to African countries, is one of the most widespread fruits in the world today. The Ecuadorian production of watermelon dates approximately from years 70, being Manabí and Los Ríos the main provinces that cultivate this fruit, for their appropriate climate for the production process required. The best temperature range average for the production of watermelon during the growing season is between 18 °C and 35 °C. The optimum climate is warm-dry with annual temperature between 23 °C and 28 °C (InfoAgro, 2000) and average annual temperature of Manabí is 24 °C. Soil preparation to sow watermelon should be done 30 days before planting, usually this work is done in a mechanized or manual way. To achieve a good harvest of watermelon it is important to know the type of soil in which it is going to be planted and for that it is necessary to carry out a soil sampling to determine if it is suitable for this crop or not. According to data from ESPAC (2017), 89.43% of producers in Ecuador have never performed a soil analysis and only 5.07% did so less than one year. The watermelon crop has a root system classified as deep, it can penetrate more than one meter into the soil. For this reason, the type of soil where the sowing is established and the adequate preparation of the land represent very important aspects in the growth of the plant. The ideal soil for sowing watermelon is deep, loose and well drained (Martínez, 2015). The selected soil must be flat, preferably loamy-clay or loamy-sandy soil, of a good physical structure not compacted, free of perennial weeds and residues of previous crops.

Watermelon cultivation is established in very variable soils, from clay loams to sand and sandy loams, so the soil preparation can change (INIFAP, 2000). Soil preparation tasks should be done according to the degree of moisture contained in it, not too wet or too dry (Casaca, 2005). In Jipijapa Canton, according to Garcés (2018), a decreasing of watermelon producers is observed in recent years. If in 2015, there were about 45 producers, in 2017 there were only 30, highlighting that there are producers who do not have the necessary training to be able to produce watermelon properly. Joa Commune, belonging to Jipijapa Canton, in 2018, opted to diversify the crops and plant the hybrid seed watermelon Glory Jumbo (Charleston Gray) on the land previously occupied by corn, which had never been plowed. To prepare the soil, due to the lack of tractors, agricultural producers decided to use only the YTO DF - 15L rotary tiller with rotary plow, which was delivered to the commune in 2014. They considered it was used in the same work in lands near the river and a good harvest of watermelon was achieved. The objective of this paper is to present the results of determining the technological-operational indices and the evaluation of the working quality of the YTO DF-15L rototiller with the rotary plow in soil preparation for watermelon cultivation in Joa Municipality. Jipijapa Canton, Manabí Province, Ecuador.

METHODS

The present research was carried out in August 2018, in Joa Municipality, located 6 km west of Jipijapa City, Manabí Province, which has an equatorial dry forest climate with an average temperature of 24 oC. Joa Commune has approximately 350 inhabitants, dedicated to short-cycle agriculture: corn, peanuts, vegetables and cucurbits (Gad, 2015). The area selected by the producers for watermelon sowing, according to the geo-referencing made with a GPS GARMIN 64 (Figure 1) was 4,69 ha. Before soil preparation, farmers cut dry pancas from the previous crop (corn) with a scythe and burned the wastes as usual practice.

To determine the type and characteristics of soil in the observation area, three zigzag soil samples were taken, each composed of 20 sub-samples, at 20 cm, 25 cm and 30 cm depth (Sosa , 2012 and Lizcano , 2017) to determine hydrophysical and mechanical parameters, bulk density, field capacity, gravimetric humidity, porosity and textural class. Soil compaction was determined with an AGRATRONIX cone-type analog penetrometer, 08180 with a precision of 2 kgf and a penetration depth of up to 60 cm in increments of 7.62 cm (AgraTronix, 2004). Obstructions in the plot due to crop residues were verified by mass weight in an area of 1 m2 (NC 34-37: 03, 2003; de las Cuevas et al., 2015).

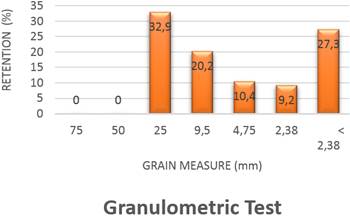

In the laboratory conditions, by means of the Bouyoucos Method and textural triangle according to USDA classification SSDS (1993), the texture of the soil was established; and through the AASHTO T 88 (2004) standard, the granulometric analysis of soil by sieving was carried out to evaluate the quality of soil softening with a rotary plow (Iglesias, 2002). The main devices used in the laboratory were a digital balance (ADAM) with sensitivity of 0,01 g to weigh material, a series of SOILTEST sieves composed of 75mm, 50mm, 25mm 9.5mm 4.75mm and 2.38mm sieves. Other devices used were a stove (QL Model 40 GC Lab Oven) capable of maintaining uniform and constant temperatures up to 110 °C ± 5 °C (230 °F ± 9 °F) and a soil hydrometer (Gilson ASTM 152 H) with sensitivity of 1 g/L. For the evaluation of the technological and operation indexes of the YTO DF-15L rototiller (Table 1) in the soil preparation work, preceding watermelon sowing, the methodology based on the Cuban standard NC 34-37: 03 (2003) was used. The operating and inactivity times were measured during work shifts using a digital chronometer (CASIO) with precision of 1 s, annotated and classified as they are described in Table 3. Subsequently, these times were used to calculate productivities per hour of different time categories and operating coefficients.

The fuel consumed by the YTO DF-15L rototiller during the work shift was obtained through the measurement at the start and end of each day, completing the fuel tank of 16 L at the end of the period. In the morning, at the beginning of the new workday, for the transfer from the field to the communal house and vice versa. To determine the depth of tillage after passing the tiller with rotary plow, the depth reached was measured, taking 30 data from the surface to the untreated area of the soil and using a 5 m flexometer with a precision of 1 mm. The working speed was calculated on the basis of measurements of the time the rotary tiller lasted in covering 50 m of distance, with three repetitions (Iglesias, 2002) and using a digital chronometer with an appreciation of 1 s. The processing of collected data was done through EXCEL spreadsheets and the AutoCAD 2014 / CivilCAD 2014 program.

TABLE 1 Technical characteristics of the YTO DF-15FL rototiller

| Model | DF-15L |

|---|---|

| Tipe | Single purpose dual axis for traction and transmission. |

| Overall dimensions, (L x W x H mm) | 2680 x 960 x 1250 |

| Gauge width, mm | Fit among 800, 740, 640 and 580 |

| Minimum clearance, mm | 182 from the floor to the bottom of the final transmission. |

| Routing width, mm | 600 |

| Minimum turning radius, m | 0.9 without rototiller |

| Weight, kg | 509/499 |

| Transmission system: | |

| a. Bands from engine to clutch | Bands type "V" |

| b. Clutch type | Double friction disc and constant contact. |

| c. Rototiller | Assembly with pressure roller chain, short format 12A-2 x 50 |

| Tractive force. | 221 kg-f |

| Rototiller speed, min-1 | 211/345 low / high |

| Diesel engine | |

| a. Model | S1100A2N |

| b. Output power, kW/hp | 12/16 |

| c. Maximum torque, N.m | 257 |

Source: YTO DF-15FL Manual (MAGAP, 2014)

RESULTS AND DISCUSSION

Characterization of the Observation Area

The condition of the soil in the observation area where the work of the YTO DF-15L rototiller with the rotary plow was evaluated is shown in Table 2.

TABLE 2 Characteristics of the experimental area, Joa Commune

| Denomination U/M Values obtained |

|---|

| Type of soil - Loamy Sandy Franco |

| Relief - Plain |

| Previous cultivation - Corn |

| Cultivation to be sown Watermelon |

| Gravimetric humidity % 18.52 |

| Resistance of the soil, before labor in the:

|

| Field capacity % 30.33 |

| Porosity % 47.73 |

| Apparent density g/cc 1.31 |

| Obstruction due to harvest kg/ha 1,200 |

The results show that the soil is suitable for the cultivation of watermelon. It is of fine texture, Franco Sandy Argillaceous, coinciding that in Jipijapa Canton soils of fine texture predominate, being 72% of the total territory clay soils and called strong or heavy soils (Gad, 2015). According to Casaca (2005), the sandy loam to franc soils are the best for the development of the plants, however, franc clayey to clayey soils can be used, the latter with amendments (aggregation of organic matter). In addition, the fine textures soils present greater possibilities of contact with the absorbent radical hairs (Humphrey, 2017).

The flat relief with a slope of less than 2%, almost no stony, good drainage and gravimetric moisture of 18.52% of the soil, allow the work of the plow tiller rotary. The field capacity 30,33%, the porosity of 47.73% classified as average and the apparent density 1.31 g/cm3, is considered high in fine textured soils (Delgadillo and Alcalá, 2010). From the measurement of the resistance of the soil to the penetration in depths from 7.62 cm to 45.72 cm, values from 0.8 MPa to 1.1 MPa were obtained, for an average of 1.0 MPa, which allows affirming that the soil was in conditions of good growing for the plant (http://equipamientocientifico.com). It was classified as in intermediate low (0.1 MPa to < 1 MPa) and moderate intermediate levels (1 MPa to < 2 MPa) according to SSDS classification (1993) and Safar et al. (2011).

Timing Results

Time recordings by the timing technique of the YTO DF-15L rototiller on three working days showed in Table 3 that the general observation time was 18.92 h, of these 15.2 h correspond to clean time of work. During the observation period on the first day, there was a break in the chain that propels the rotary plow (Figure 1) at 3.43 h after the start of the work and for the elimination of this fault, 0.53 h (T42) were necessary. A technological failure was also recorded (Figure 2) due to soil obstacles, which was solved in 0.13 h. The time of transfer to the field and vice versa was 2.38 h, which is related to the distance of the field from the parking place.

TABLE 3 Results of measuring working time of the YTO DF-15L

| SYMBOL | DENOMINATION | h |

|---|---|---|

| T1 | Clean work time | 15,2 |

| T31 | Time for the execution of the daily technical maintenance | 0,48 |

| T42 | Time to eliminate technical failures | 0,53 |

| T5 | Rest time of service personnel of the testing machine | 0,2 |

| T61 | Transfer time to the field or vice versa | 2,38 |

| Total observation time | 18,92 |

According to the classification of the types and forms of movements of the sets, the operator used the rolling movement (Figure 3), whose characteristic is that the work pass is made along and across the field, avoiding any time losses in turning.

Productivity Indices

Table 4 shows the results of calculating productivity indices of the YTO DF-15L rototiller during the observation period.

TABLE 4 Productivity indices of the YTO DF-15L

| Name of the indices | Value | U/M |

|---|---|---|

| Volume of work done | 0,92 | ha |

| Productivity per hour of clean time (W01) | 0,06 | ha/h |

| Productivity per hour of operating time (W02) | 0,06 | ha/h |

| Productivity per hour of productive time (W04) | 0,06 | ha/h |

| Productivity per hour of shift time without failure (Wt) | 0,05 | ha/h |

| Productivity per hour of exploitation time (W07) | 0,05 | ha/h |

The working productivity of a rototiller is a function of the width, speed and efficiency of the work. The productivity per hour of clean time (W01), operating time (W02) and productive time (W04) was approximately 0.06 ha/h, considering that there were no expenses of auxiliary time and expenses of time for the maintenance and the elimination of failures were minimal. Productivities by other time categories reached the approximate value of 0.05 ha/h. These results are similar to the productivity of 0,05 ha/h obtained during the plowing tests of the DF-15L and DF-12 tractors Kebede & Getnet (2016). Nevertheless, they were lower than those achieved by the KUBOTA rototiller in strawberry set, which was 0.09 ha/h and 0.07 ha/h of clean and productive time respectively in soil preparation for rice (Chedré et al., 2005).

Operating Coefficients

The values of the operating coefficients, calculated based on primary timing data, are shown in Table 5.

TABLE 5 Operation coefficients of the YTO DF-15L

| Denomination of the coefficients | Value |

|---|---|

| Coefficient of work passes (K 21) | 1,00 |

| Technological service coefficient (K 23) | 1,00 |

| Technical maintenance coefficient (K 3) | 0,97 |

| Technological safety coefficient (K 41) | 0,99 |

| Technical safety coefficient (K 42) | 0,97 |

| Coefficient of use of productive time (K 04) | 0,96 |

| Coefficient of utilization of exploitative time (K 07) | 0,96 |

As it can be seen, practically all operating coefficients reached values equal to or close to 1.0 during the observation period, due to the speed with which they eliminated the chain failure and technological failure. These results are largely due to the experience of the operator of the rototiller and his constant dedication to work.

Fuel Consumption

The fuel consumption of the YTO DF-15 L rototiller in the preparation of 0.92 ha of soil was 15.2 L. The specific cost per unit of work performed of 16.52 L/ha, which is less than 18.42 L/ha of the DF-15L Kebede & Getnet (2016), but superior to the consumption of the KUBOTA rototiller that reached values between 13-15 L/ha (Chedré et al., 2005). The fuel expense per hour of exploitation time was 0.91 L/h, which is approximately the reported of 1.00 L/h by the DF-15L walking tractor (Kebede & Getnet, 2016).

Quality of work

The soil preparation for watermelon sowing was carried out in two rotary plow tiller passes. In the first working pass of the rototiller at an average speed of 1.7 km/h, an average depth of 8.9 cm ± 1.3 cm was recorded. In the second pass, an average depth of 15.9 cm ± 1.2 cm was reached at a working speed of 1.84 km / h. The working width of the rotary plow was on average 68 cm. The working speed of the tiller was between the first and second theoretical speeds (1.4 km/h and 2.5 km/h), depending on the manufacturer (Manual YTO). The depth of work achieved in two passes is similar to that reported (15.23cm ± 1.23 cm) in the DF-15L rototiller test in plowing (Kebede & Getnet, 2016).

By preparing the soil, conditions are created to facilitate the germination of the seed or the establishment of the transplant and subsequent development of the plant. Each climate-soil-cultivation system presents specific problems that will require different tasks. In the case of watermelon, it must be taken into account that its root system is of deep type and any obstacle present for the development of it, will affect the crop (Martínez, 2015). The traditional or conventional system of soil preparation is the use of plow, harrow and rake, with the plowing to the depth of up to 20 cm ... 30 cm (Casaca, 2005 and Masabni and Lillard, 2013). Other authors do not specify the depth of soil preparation, referring that for the planting of watermelon in the open air, harrow or plow works are necessary to loosen the soil. There are experiences of soil preparation to sow watermelon only with hand tools. The project developed in Ecuador "Ecological production and marketing of watermelon and onion in “Canta Gallo Jipijapa Canton" is one of them. In that project, it was decided not to perform any type of mechanized tillage, so furrows were made manually, spaced at 50 cm, in parallel lines (Quimís, 2007). In Joa Commune, they have the experience of soil preparation with two passes of YTO DF-15L Rototiller, in Loamy Sandy Franco soils near the river and obtaining good harvest of watermelon.

Based on the above and taking into account that the soil in the observation area has good conditions for watermelon growth (not compacted), the soil preparation depth reached by the YTO-DF-15L rototiller can be considered acceptable. It is recommended to the producers that, before planting watermelon, form ridges of height of 10 cm to 20 cm with a hand tool, to facilitate the development of roots, improve aeration, and manage water and fertilizers (Martínez, 2015). The quality of soil loosening was determined by the ratio of the mass of lump fractions smaller than 50 mm to the total mass of the soil sample, expressed in hundreds. Approximately 80% of lumps of 1 mm to 50 mm in size should be granted at the upper level and the formation of fractions of more than 75 mm is not allowed (Iglesias, 2002; Yarullin, 2015). The size of clods after the rotary plowing step was determined by granulometric soil analysis by sieving (Figure 4).

As it can be seen in Figure 5, there was no lump retention in the 75 mm and 50 mm sieves. The highest clod retention (492.79 g) corresponded to the 25 mm sieve representing 32.9% of the total mass; of the grains smaller than 2.38 mm, a mass of 409.9 g (27.3%) was obtained. The results show that the quality of loosening was satisfactory.

CONCLUSIONS

The technological and exploitation evaluation of the YTO DF-15L rototiller in the preparation of Franco Sandy Argillaceous soil, which meets the requirements for the sowing of watermelon, showed satisfactory results in the use of clean working time, which was equal to 15.2 h out of a total of 18.72 h of observation.

The productivity per hour of operation time was 0.05 ha/h, the coefficient of use of productive time was 0.96. During the observation period, only one break in the rotary plow propellant chain was recorded.

All the operating coefficients reached values equal to or close to 1.00 during the observation period, obtaining the coefficient of technical security the value of 0.97.

The quality of the work done by the rotary plow is considered satisfactory, fulfilling the agrotechnical requirements for the softness of the superficial layer of soil. The depth of soil preparation reached of 15.9 cm ± 1.2 cm at a working speed of 1,84 km / h, is acceptable. It is recommended, before sowing watermelon, to form ridges from 10 cm to 20 cm height with manual tool, to facilitate the development of roots of the plant, improve aeration, and for the management of water and fertilizers.

texto em

texto em