INTRODUCTION

Increasing the efficiency of water and energy use in agriculture is of vital importance in the face of climate change Selim et al. (2018), so it is necessary to generate adaptation actions that allow adjusting planning, operation and evaluation processes of irrigation service Ojeda et al. (2012). In this context, different efficiency indicators have been proposed (De Lima et al., 2008, Rodríguez et al., 2011, Schons et al., 2012, Bolognesi et al., 2014 and Won et al., 2016), fundamental factors to help in the decision-making process regarding improvements in the water distribution system, in order to optimize energy and economic consumption (Tarjuelo et al., 2015).

There are multiple indicators of water efficiency; the most common are irrigation efficiency and water use efficiency. Low efficiency in irrigation systems affects agricultural yields (Camejo et al., 2017 and Zhuo and Hoekstra, 2017). The efficiency of the sprinkler irrigation system can be evaluated by the Uniformity Coefficient of Heerman and Hein and by the Efficiency of Application, while the specific energy in these systems is evaluated through specific power or consumption indicators (De Almeida et al., 2017). For example, in Brazil, they can be characterized in terms of their specific consumption between 0,2 to 0,6 kWh m3 (De Lima et al., 2008). However, they are not sufficient to characterize the overall efficiency of an irrigation system (López et al., 2017).In this sense, the objective of this work is to analyze the efficiency criteria for the evaluation of projects and operation of sprinkler irrigation in the agricultural companies Cubasoy and La Cuba of various crops, in the province of Ciego de Ávila.

METHODS

The research was carried out in the enterprises Cubasoy and La Cuba in the hydrogeological sector south CA-II-1 and north CA-I-8, while their average water levels behave in 9.66 m and 17.53 m, respectively, according to the historical series of 30 years (1985 to 2015). Table 1 shows the characteristics of the central pivot irrigation system that were analyzed.

Table 1 Characteristics of the pressure irrigation system

| Zone | Pivot | Sprinkler | Area (ha) | Topographic slope (m) | Suction pipe* | Drive pipe * | Side pipe ** | |||

|---|---|---|---|---|---|---|---|---|---|---|

| DN (mm) | L (m) | DN (mm) | L (m) | DN (mm) | L (m) | |||||

| 2415 | Rotator | 63,86 | 18,0 | 203,2 | 17,50 | 203,20 | 8,0 | 168,30 | 451 | |

| 3120 | Rotator | 58,87 | 16,9 | 203,20 | 20,0 | 203,20 | 12,0 | 168,30 | 433 | |

| 3116 | Rotator | 57,25 | 17,7 | 203,20 | 18,30 | 203,20 | 10,0 | 168,30 | 427 | |

| Lango | Spray | 62,30 | 9,1 | 203,20 | 7,65 | 203,20 | 12,0 | 168,30 | 445 | |

| Higinio | Spray | 62,50 | 9,0 | 203,20 | 8,0 | 203,20 | 31,0 | 168,30 | 446 | |

| Frutero | Spray | 41,00 | 10,1 | 203,20 | 9,30 | 203,20 | 6,50 | 168,30 | 362 | |

* galvanized iron; ** galvanized steel; DN nominal diameter; L length of the pipe

Dissipated Power

The criterion of efficiency in the irrigation systems begins in determining the minimum work to pump the water used by the crop. From the physical criteria, the useful power for the irrigation system can be obtained from the water level in the well and the most unfavorable point of the irrigation area (Equation 1). While, the powers dissipated in each of the element of the irrigation system (suction, pump-motor, drive, sprinkler) depending on the efficiency of application for 80% of the area properly irrigated, can be expressed by the expressions (2; 3 and 4).

Where:

P usr |

- useful power of the irrigation system (kW) |

P dbm |

- power dissipated in the motor pump set (kW) |

P de |

- power dissipated in the element (kW) |

P dasp |

- power dissipated in the sprinklers (kW) |

H m |

- manometric height of the pump (m) |

h g |

- topographic difference between the water level in the well and the sprinkler in the most unfavorable condition of the system (m) |

Q |

- flow measured at the pump outlet (m³ s-1) |

γ |

- specific weight of water (9.806 kN m-³) |

EA80 |

- efficiency of water application (%) |

Δh |

- the loss of load in the elements of the system (m), being the pipes and accessories |

h asp |

- manometric height of the sprinkler (m) |

ƞ bm |

- performance of the pump-motor assembly (decimal) |

The power dissipated in the irrigation system according to the efficiency of application for 80% of the adequately irrigated area, the geometric slope and the load losses of the elements of the system are represented by the following equation:

Where P dsr is the power dissipated in the irrigation system (kW); ∆h s the loss of load in the suction (m), ∆h i the pressure drop in the discharge pipe (m) and Δhasp the head loss in the sprinkler (m);

Criteria of Efficiency of the Irrigation System

The efficiency criteria were based on the specific consumption of energy of the irrigation system in accordance with the following equations:

Where:

CEN BM |

- standardized energy consumption of the pump-motor assembly (kWh m-3 100-1 m-1) |

CE E |

- specific energy consumption (kWh m-3) |

CEu 80 |

- consumption of useful energy (kWh ha-1) |

CE Asp |

- specific consumption in the sprinklers (kWh mm-1 ha-1) |

CEN R |

- consumption of the specific energy normalized in the irrigation (kWh mm-1 ha-1 100-1 m-1) |

E R |

- percentage of energy actually used (%) |

T R |

- time it takes for the lateral to apply a watering (h) |

A |

- irrigation area of the central pivot (ha) |

The flow rate and liquid velocity in the impulse pipe was determined by means of a PCE-TDS-100 ultrasonic meter with an accuracy of ± 1.5%. The power in the electric motor was obtained from a MI 2392 Power Q Plus grid analyzer with an accuracy of ± (1% + 0.5 V), ± (2% + 0.3 A), ± (3% + 3 Wh), ± 0.06 Cosine φ and ± (0.5% + 0.02 Hz). The pressure reading was taken at the pivot, at the towers and at the end of the side by the high precision digital manometer Type CPG1500 brand WIKA with an accuracy of 0.05%. Climatic variables were measured from the AVM-40 Mobile Climatic Anemometer (Kestrel 4000) with an accuracy of ± 3% in wind speed, ± 1 ° C in temperature and ± 3% relative humidity of air.

RESULT AND DISCUSSION

Table 2 shows the results of the variables measured in the irrigation systems. It is observed that the flows in the irrigation systems range between 60,10 to 76,67 L/s. However, the manometric heights of the centrifugal pumps were superior in the Cubasoy Company and it, consequently, reached an average electrical consumption of 69%. The prevailing wind speeds in the central pivots are classified as low winds according to Tarjuelo (2005), which favorably influences an application efficiency for 80% of the adequately irrigated area from 77,30% to 82,80%; values higher than those reached by Román et al. (2013) and similar to those obtained by Palacios et al. (2017).

Table 2 Measures of hydraulic, energy and climate variables

| Zone | Pivot | Hidr (L s-1 ha-1) |

|

|

Pe (kW) | EA80% | Weather conditions | ||

|---|---|---|---|---|---|---|---|---|---|

| T (ºC) | HR (%) | V (m s-1) | |||||||

| 2415 | 1,20 | 83,02 | 47 | 70,30 | 82,80 | 31,20 | 70,30 | 2,0 | |

| 3120 | 1,23 | 86,17 | 35 | 72,0 | 80,0 | 32,40 | 63,60 | 2,77 | |

| 3116 | 1,21 | 88,52 | 56 | 80 | 81,02 | 33,0 | 75,40 | 2,30 | |

| Lango | 0,96 | 55,41 | 56 | 40,48 | 81,40 | 29,30 | 79,15 | 1,60 | |

| Higinio | 1,15 | 69,92 | 68 | 69,87 | 77,30 | 30,0 | 69,50 | 2,20 | |

| Frutero | 1,62 | 54,43 | 50 | 44,22 | 80,88 | 26,0 | 80,0 | 1,30 | |

Hidr is the hydromodule; EA 80% the application efficiency for 80% of the area adequately irrigated; T the temperature; HR the relative humidity of the air and V the wind speed.

Table 3 shows the results of the power dissipated by each of the components of the irrigation system. It is appreciated that the highest energy consumption in the pumping station 3116 is 19,71 kW and a power dissipated in the irrigation system of 33,03 kW, this registered the lowest efficiency of the pump set of 62,78% product to the operation time. However, the rest of the efficiencies of the motor pump set in the other irrigation systems ranged from 69,5 to 74,10% classified as excellent according to Abadia et al. (2008). The favorable results were in Lango pumping station with dissipated power of 4,37 kW and a power dissipated in the irrigation system of 17,24 kW.

Table 3 Power dissipated by component

| Parameters | Cubasoy | La Cuba | ||||

|---|---|---|---|---|---|---|

| 2415 | 3120 | 3116 | Lango | Higinio | Frutero | |

|

|

11,16 | 9,61 | 9,77 | 4,37 | 5,34 | 5,32 |

|

|

7,82 | 10,74 | 19,71 | 7,82 | 10,64 | 8,78 |

|

|

10,98 | 9,48 | 11,11 | 7,05 | 10,68 | 7,73 |

|

|

8,14 | 7,56 | 7,71 | 4,92 | 8,24 | 5,49 |

|

|

28,21 | 28,73 | 33,03 | 17,24 | 28,46 | 19,63 |

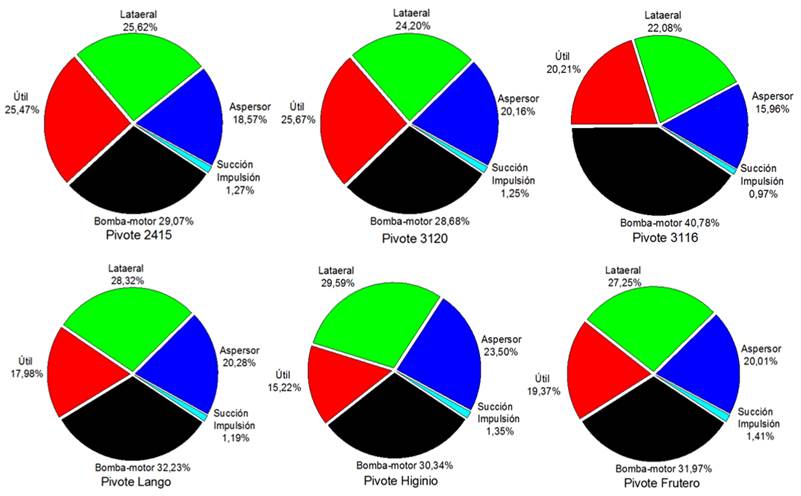

Figure 1 shows the percentages of the power dissipated in each element of the irrigation system. It is confirmed that the component with the highest power consumption is the pump-motor assembly and the 3116 consumes 40,78% of its electrical energy to convert it into energy, while the pumping station 3120 only uses 28,68%. These obtained values are close to those reached by De Lima et al. (2008). In Figure 1, in the laterals of the central pivots, the dissipated powers oscillate from 24,20% to 29,59% with lengths of 309 m to 451 m. The pivot 3116, equipped with the Rotator sprinkler, achieved a lower dissipated power of 15,96%, which is higher than those obtained by De Lima et al. (2008), parameter that is attributed to the years of the irrigation system in operation without receiving adequate maintenance. However, the useful powers of the central pivots of Cubasoy Company were superior to those of the Cuba, because it uses the highest hydraulic variables, flow and pump gauge height and, consequently, electrical power.

The stratification of the power dissipated in each component of the irrigation systems provides a view of the loss of energy, but according to De Lima et al. (2008), it is restricted because it is considered that all the water pumped is harvested by the crop. Therefore, it is necessary to obtain indicators expressed in terms of the efficiency of application.

Table 4 shows the results of the hydraulic and energetic efficiency of the central pivot irrigation system. The most favorable pivot to the consumption of useful energy was that of Lango with 3,93 kWh ha-1 and the highest consumption was in the pivot 3116 with 9,55 kWh ha-1 for 80% of the area adequately irrigated at 81,40% and 81,02% of the application efficiency of the irrigation system, respectively. However, the specific energy consumption for pumping one cubic meter ranged from 0,18 kWh m-3 to 0.32 kWh m-3. These results are lower than those obtained by De Lima et al. (2008), Schons et al. (2012) and Brenon et al. (2018), due to the study areas of these authors show topographic differences greater than 20 m. However, the comparison of specific values of energy consumption to refer to pumping stations must be made with caution because of the different factors involved.

Table 4 Efficiency of irrigation system

| Parameters | Cubasoy | La Cuba | ||||

|---|---|---|---|---|---|---|

| 2415 | 3120 | 3116 | Lango | Higinio | Frutero | |

|

|

0.31 | 0.32 | 0.36 | 0.34 | 0.33 | 0.34 |

|

|

0.25 | 0.28 | 0.32 | 0.19 | 0.23 | 0.18 |

|

|

8.21 | 5.71 | 9.55 | 3.93 | 5.81 | 6.46 |

|

|

0.36 | 44.96 | 81.80 | 39.72 | 69.13 | 58.14 |

The pivot with the best performance of the normalized energy consumption of the pump-motor assembly was the 2415 with 0,31 kWh m-3 100-1 m-1, which means that the operating point of the irrigation system operates with a stable efficiency over 80%. However, it was identified that the selection of the pump-motor assembly for the pivot 3116 was not the most suitable, because it has the highest consumption of 0.36 kWh m-3 100-1 m-1. However, the results obtained are lower than those determined by De Lima et al. (2008) and Schons et al. (2012).

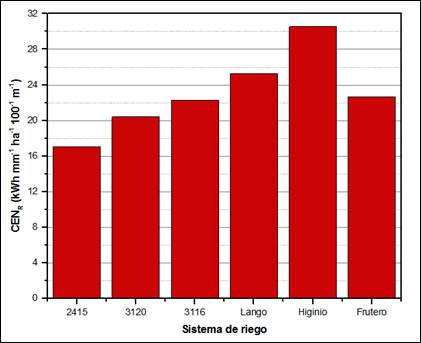

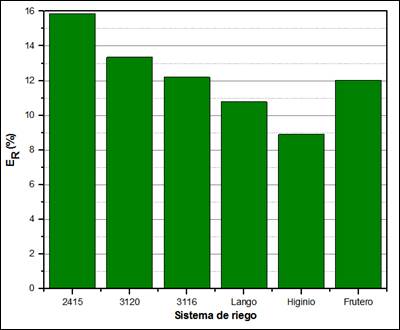

Figure 2 shows the specific energy consumption normalized in irrigation. It is observed that the pivot 2415 obtains the lowest specific energy consumption normalized in the irrigation of 17.16 kWh to provide one millimeter of water in 80% of the adequately irrigated area, when the geometric height is less than 100 m. However, Figure 3 shows the percentage of energy actually used and the 2415 system reaches 15.80% with a higher percentage of energy actually used in irrigation. That means that the pump-motor assembly, the pipes, the leakage, water losses, pressure regulators, sprinklers and water losses due to evaporation and drag dissipate 84.20% of the energy.

In general, Figures 1 and 2 show that the central pivots of Cubasoy Company have lower specific energy consumption and, in turn, greater energy actually used in irrigation. This result is due to the sensitivity analysis performed to the energy indicators that for each 1 kW of power measured in the electric motor, the specific energy consumption normalized in irrigation is 0,25 kWh mm-1 ha-1 100-1 m-1. While, for every 1 m of topographic difference between the water level in the well and the sprinkler in the most unfavorable condition of the system, increases 0,88% the percentage of energy actually used. These factors are also due to the characteristics of the curves of the centrifugal pumps placed in the pressure irrigation systems.

CONCLUSIONS

The stratification of the power dissipated in each component of the irrigation system allowed identifying the pumping station with the highest energy consumption for the immediate maintenance of its elements. The central pivot 2415 reached the best performance of the efficiency indicators with a normalized energy consumption of the pump-motor set of 0,31 kWh m-3 100-1 m-1, a specific energy normalized in the irrigation of 17,16 kWh mm-1 ha-1 100-1 m-1 at an application efficiency of 82,80% for 15,80% of energy actually used in irrigation.

It is reaffirmed that efficiency criteria contribute to the valorization of efficient irrigation technologies for the project modality and in the specific operation conditions for optimum crop productivity, based on a sustainable use of natural resources; as well as it allows improving the decision making for the previous maintenance.

texto en

texto en