Introduction

With the continuous raising of the standard of living, the air conditioning of buildings has become a necessity; in many cases to ensure that their living conditions meet the comfort requirements of its occupants, which results in greater satisfaction of them and, in other cases, as the building's fundamental equipment to meet the intrinsic function of the same.

The air conditioning installations are today one of the most important facilities of a building, for several reasons: In the aspect of investment due to the high economic value of the same, which can constitute between 10 and 20% of the amount of the building in centralized facilities in new buildings. In the aspect of exploitation for the amount of energy consumption that probably constitutes the most important of the energy costs of the building, greater than the energy expenditure in lighting and other electrical consumption of the building. In the aspect of maintenance and conservation for the dedication they demand, the cost of its components and the needs of specialized personnel in these tasks. Finally, in the functional aspect, due to the high incidence of the lack of this service in a given moment in the activity of the building and its users. For a correct design, it is necessary to know all the potentialities of each existing equipment in the market.

Knowing that the air conditioning installations in a building require special attention in order to get the most out of them, rationalizing their costs to the maximum, both from the aspect of the initial investment, and subsequently, their energy consumption and maintenance and conservation costs. The objective of this article is to provide a synthesized review of each system according to its distribution and issuance. In addition, considering that one of the biggest problems of indoor climate control is the emission of greenhouse gases and the consumption of electricity, systems that use renewable energy sources will be addressed, in order to contribute to the diffusion of this knowledge.

Development

The air conditioning consists of creating conditions of temperature, humidity and cleanliness of the air suitable for comfort within the inhabited spaces. To achieve this goal, HVAC systems are used. There is a great variety of designs and equipment for air conditioning, which, together with the fact that several systems share common characteristics, makes the task of establishing a classification with net differences between them complex.

In a general way HVAC systems can be classified according to their emission form into unitary, individual and collective systems. Unitary systems are those in which each element is an independent heat or cold generator. The installations or individual systems are those in which the production of cold or heat is independent for each user. Finally, collective facilities are those in which the production of cold or heat serve to a group of users in the same building.

Another classification is according to thermal energy transfer medium. The unitary and individual installations are almost always formed by autonomous equipment’s, in which the cold production takes place in the same machine. These types of systems are also called direct expansion systems. In this case, when the components of the same equipment are located in the same unit, they are called compact systems. When the condenser and / or the compressor are located outside, while the evaporator in an indoor unit, they are called split systems. The collective facilities have a common cold and / or heat production plant and one or several heat-carrier fluid distribution networks to the air-conditioned premises. Another denomination is centralized systems. When the heat-carrying fluid is air, the air conditioning system is called All- Air; when it is water, All-Water and finally mixed Air-Water systems. Others sophisticated configurations are: the solar cooling systems, Independent control of temperature and humidity system (ICTHS) and Dedicate Outdoor Air Systems (DOAS).

The choice of the air conditioning system in each case, will be optimal for the resolution of a specific problem. It must be carefully reviewed, always taking into consideration those differential factors that make, in each case, one application of another. Normally the factors that make the difference before the decision to choose one type or another of installation are the following: Criteria of interior zoning in the building; zoning by use; zoning by schedule; zoning by geographical orientation; size of the defined zones; needs for the supply of external air for ventilation and conservation of the quality of the indoor environment; acoustic comfort criteria; importance of the sound level inside the occupied premises; variability of thermal loads; possibilities of heat recovery; the relationship "quality / price, the architectural constraints as the spaces available to locate the air conditioning facilities among others.

Below are some specifications of the following HVAC systems: all air, all water, air-water, direct expansion and other sophisticated systems are showed.

All Air systems, the systems are often used in the buildings that require individual control of multiple zones, or places where accurate and precise control of space environmental is required. Single-supply air system can be adapted to provide all-air air conditioning to many zones by adopting different schemes: Single Duct, Constant Volume System (CVS), Single Duct, and Variable Volume System (VAV). Dual Duct, CVS and VAV. Single duct normally consumes less energy than dual duct system. But just can provide cooling or heating, no both (simultaneously) as the dual duct. The VAV is designed with a volume control damper, controlled by the zone thermostat, in each zone. This damper acts as a throttle to allow more or less cool air into the zone. The VAV system adjusts for varying cooling loads in different zones by individually throttling the supply air volume to each zone. VAV is more efficient than constant volume systems. VAV systems usually reduce the amount of total air delivered to the space during part-load conditions to achieve energy efficiency. However, when the space loads change, this can result in loss of indoor humidity control, even though indoor space temperatures remain at acceptable levels.

The advantages are: effective room air distribution and ventilation under widely varying load conditions; Major equipment is centrally located in dedicated service space, which allows maintenance to take place in unoccupied areas, can be remotely located, well away from conditioned space. It helps to reduce noise levels in occupied spaces; present great opportunities for energy conservation such as heat recovery wheels; heat recovery systems can also be easily integrated into main air-conditioning units the greatest potential for use of outside air for ¨free¨ cooling. Generally, all air systems are used in IT data center, hospitals, clean rooms etc. where precise control of space humidity is required. The main disadvantage are: Additional requirement add to building envelopment for duct space and higher installation and operation costs, use significant amount of energy to move air (approximately 40 % energy use is fan energy); providing ready maintenance accessibility to terminal devices requires close coordination between mechanical, architectural, and structural designers

In all water systems, or hydronic systems, selecting chillers is a critical step. The chiller plant is usually consisted of chillers, cooling towers, condensing water pumps, chilled water distribution pumps, chilled water storage tanks, and distribution pipes. Chillers are available in different ranges in terms of cooling capacity depending on a specific compressor type and coefficient of performance (COP) as see in table 1, and it is a key component that decides the system configuration of the primary system. Many design options of chilled water system are implemented to achieve desired chilled water temperature. Each option depends on flow, required temperature, and system configuration and operation strategy. All water systems are used for existing building when space is limited. The design operation and maintenance of chilled water plants has a very large impact on building energy use and energy operating cost.

Table 1 Performance and cooling capacities of various commercial chillers. Kohlenbach & Jakob (2014).

| Chiller type | Cooling capacities | COP |

| Absorption | 10 to 20 500 kW | 0.5-1.1 |

| Adsorption | 19 to 1 000 kW | 0.5-0.65 |

| Centrifugal | 280 to over 14 MW | 6.1 |

| Reciprocating | 7 to 1600 kW | 2.81 |

| Screw | 100 to 4400 kW | 2.84 |

| Scroll | 528 to 1,056 kW | 3.02 |

The chillers in the plant can be connected in series or in parallel. Multiple chiller systems are more common than single chiller systems. Chillers with different capacities guarantee high energy efficiency at partial loads. If the system is properly designed then energy required to operate a second chiller can be conserved. A study conducted by Yu & Chan (2007) four design options were analyzed to decide the optimal number and size of chillers operating with maximum system performance. Result estimated that electricity savings of 10.1% could be achieved with six chillers of three different sizes instead of four equally sized chillers. Conventionally, a centrifugal chiller is more efficient at full or nearly full load, while rotary screw type chillers usually have the best efficiency at partial load. In contrast, reciprocating chillers performance varies and the exact unit specifications should be verified.

All-variable speed chillers (VSC) plant can operate mucho more efficiently at part load that conventional constant speed plant. Qureshi & Tassou (1996), established that has been applied successfully to perform capacity modulation for chillers compressor. The use of VSC and/or variable flow, primary -only pumping was a viable means to eliminate an important drop in systems performance at part load operation while accommodating the low delta T syndrome of chilled water circuits.

Chillers could be condensed by water or air. Spite that water cooled systems have a great efficiency than air cooled, air cooled chillers are dominant. The main causes of the lack of proliferation of water cooled spite the efficiency are: the progressive insufficient water supply, air cooled is easy for maintenance, less corrosion, les incrustations and there nor risk of freezing issues. Water cooled chillers need special requirement regarding water treatment regimens, beside the additional cost. Water must be of good quality and treated further to avoid scaling, corrosion, fouling and biological growth. The risk of bacteria must be prevented by proven chemical or physical controls.

Chillers also allowed the possibility of implement the thermal energy storage (TES). It could be a key for a better power generation management. Their design allowed the reduction of the installed capacity with a consequent reduction of fixed costs; reduced peak demand and energy consumption in times of increased cost of electricity also possible to decrease the electricity bill. Other advantages associated with TES are: more efficient and elective system operation, improved indoor air quality and increase flexibility of operation. Henze, et al. (2008), reported 25% savings of the operation cost, when introducing in a chilled water TES system into a colossal air-conditioning system for a pharmaceutical industry, Gang, et al. (2016), using the uncertainty-based design optimization method investigated the performance of a District cooling systems integrate with ice storage. The results revealed that the annual operation cost had a probability of 80 % to be lower than a system without TES.

As an important advantage in the all water systems the thermal distribution system required significantly less space compared to the all-air systems, those systems are suitable on existing building with limited space. Individual room control and simultaneous cooling and heating are also possible. They are well suited for retrofit applications due to their distribution efficiency. But maintenance demands can be high and maintenance must be performed on terminals within occupied spaces. Condensate drain pans and a drain system are required; in addition, they must be cleaned periodically. Ventilation is not centrally provided or controlled and is often accomplished by opening windows or via an outdoor air inlet at each terminal unit; thus, providing for acceptable indoor air quality can be a serious concern. Relative humidity in spaces may be high in summer, particularly if modulating chilled-water valves are used to control room temperature.

In case of Air -Water system their use the best features of all air and all water. Most of the energy is carried in the water. Often the air quantities distributed are only enough for ventilation. Therefore, the total shaft and ceiling space required is small. In addition, the air is usually carried at high velocities. Air-water systems are typically categorized in three types, such as induction system with two or four pipe systems, fan-coil systems, and radiant panels. In such systems, it is possible to provide simultaneous cooling and control on individual zone in an economic way through thermostats. However, the overall operation and control are complicated due to handling both primary air and secondary water. In general, such systems are limited to perimeter zones. Initial cost of these systems could be high compared to all air systems.

Air-Water combination is suitable for buildings with large exposures. Since there is no latent load on cooling coil, troubles due to condensation do not occur. It prevents marshy or damp regions in the conditioned space. This configuration needs very less apace as compared to all air systems for same capacity, it is more suitable for individual room/ zone control, simultaneous cooling and heating with 4-pipe. As a disadvantage the initial cost of these systems could be high compared to all air systems. Control of space humidity is limited, Separate ventilation system must be used to supply fresh air, which adds to cost. Also control of ventilation air is not precise. Condensate may cause problems of dampness in ceiling or walls if condensate drain fails. Require higher maintenance compared to all-air systems. As systems are complicated with greater extent of controls, normally air-water systems are costlier than all water systems and Constant supply of fresh air has to be supplied to all zones, no matter whether spaces are occupied are not. Because control is only for cooling/ heating coil through room thermostat.

In the Direct expansion (DX) systems or unitary refrigerant-based systems usually are best for low cost and very low load intermittent applications; they are simple and inexpensive room control and lower initial cost compared to central systems. For example: Windows units are primary found in residential applications, and they not have ducted air distribution.

The appearance and noise of these units limit their application. Rooftop units are primarily applied in low-rise buildings with flat roofs. For better air distribution in the conditioned space the conditioned air should be ducted from the rooftop unit to multiple outlets instead of introducing the total airflow rate at one position. The split system, serving such small facilities, usually conveys the conditioned air through ducts to the spaces served by the conditioner is a ductless product were designed as quieter, more efficient alternatives to window units. Multi-split was designed mainly for small to medium commercial applications where the installation of ductwork was either too expensive, or aesthetically unacceptable. The heat pump (HP) offer one of the most practicable solutions to the greenhouse effect offering energy efficient and environmentally friendly heating and cooling in applications ranging from domestic and commercial buildings to process industries.

An important improvement of DX systems it can found multi-and variable-speed drives, novel compressor, fan, motor, and heat exchanger designs, electronic expansion valves, and advanced controls. Other attractive improve is the Variable refrigerant flow (VRF) air conditioning systems due to better energy performance than traditional systems. VFR provides a better occupant's thermal comport, energy savings, flexible operation, ease of installation, low noise, zone control, and comfort using all-electric technology.

The main energy saving of VRF systems was due to: the used of variable speed air cooled compressor, the reduction of fan energy and the ductwork for space cooling or heating zones, the capability of heating and cooling at the same time for different zones without required for reheat, the ability of providing heat recovery between zones at the same time, the used of refrigerant instead of water lead to required less energy to transfer the fluids heat and for last using outside air systems with energy recovery.

VRF systems achieved ranging from 10% to 60% of energy savings depending on climate and the type of system displaced, among other factors. Studies relate to the saving potential it found in Amarnath & Blatt (2008). The multi-split VRF system has high energy efficiency under part load condition, due to the modulation of the compressor speed to adapt the load changing. In addition, duct losses in the multi-split VRF systems can be almost eliminated due to the in-space location of the indoor units estimated to be 10% up to 20% of total airflow in a ducted system. Compared to conventional air conditionings are its high respond to fluctuations in space load conditions. These systems are suitable for cases when have different zones with different space conditioning requirements.

The main disadvantages of VRF system is its high initial cost and the ventilation issue which they cannot provide any fresh air to the indoors during the conditioning processes. To overcome this drawback, an additional ventilation system is required which incremental the total cost. The design of VRF systems is more complicated and requires additional work compared to designing a conventional DX system. Long refrigerant runs and large numbers of connections could result in refrigerant leakage that could be significant, causing safety issues and repair difficulties.

Total costs of VRF systems are likely to be about 5% to 20% higher than chilled water systems of similar capacity. About 30% to 50% more than equivalent capacity single package ducted system and more than twice as much as packaged terminal units. Study conducted by Cassidy & Sweet (2000), compared the whole-life costs of four common air-conditioning systems used in a modern new-build. The result showed that, a system with four-pipe fan-coil units was 53% more expensive than the chilled ceilings option, the variable air volume system was 74% more expensive, and the multi-split VRF was 111% more expensive.

Santamouris (2016), reported that Split systems present the highest share of the market with a total sale close to 74.5 billon US$. VFR systems present a significant growth as well, reaching a total market value close to 9.7 billon US$. A less share was observed for the PTAC, Indoor packaged and windows air conditioning systems. Unitary systems are less flexible in terms of air flow rate, condenser and evaporator sizes. Power consumption per kW could be higher compared to central systems, see table 2. The efficiency parameters in the case of this systems is defined as energy efficiency ratio (EER), in British thermal unit per Watt-hours (Btu/(Wh)), and defined by equation EER = 3.412 COP. Cooling SEER to EER estimated using de-rating estimates from Table 2 of the authors Cutler, et al. (2013).

Table 2 Current performance of residential cooling technologies.

| Air conditioning type | Measured | Unit |

|---|---|---|

| Residential air conditioning | 10.8 | EER |

| Residential Air Source Heat Pumps | 14 | SEER |

| Residential Ground Source Heat Pumps | 14.2 | EER |

| Residential Gas Heat Pumps | 0.6 | COP |

| Commercial Roof Top Air conditioner | 11.2 | EER |

| Split | 14.9 | SEER |

The drawbacks of unitary systems are that there are relatively few options with respect to sizing the evaporator, condenser, fans, compressor, and controls. Since each unit must be capable of meeting the peak load of the space it serves, the installed capacity and connected electrical load are usually larger than with a central system. Other problem probe by different authors is the quality of indoor environment. Ai, et al. (2016), referred that a deficiency of room air conditioner was the lack or very little outdoor air. In studies conducted in residential building, Park, Jee & Jeong (2014), showed that the ventilation rates were less than the minimum requirement recommended by ventilation standards, ASHRAE Standard 62.1, 2013 of 7.5 l/s/p. Those associated with low ventilation rates and excessive CO2 concentrations (>1000 ppm) reported by Beko, et al. (2010). Other studies (Sundell, et al., 2011) showed the strong correlations between insufficient ventilation and the prevalence of illnesses and sick building syndrome, beside insufficient ventilations in bedrooms was responsible for a poor sleep quality and reduction of physical and physiological performance of persons.

Technologies based renewable energy resources are also penetrating in the HVAC sector. The main reasons are environmental issues due to CO2 emissions, and ozone depleting mediums in conventional systems i.e. CFCs, and HCFCs, due the probability of working fluids escaped through leakages from cooling equipment during normal operation (filling or empting) or after accidents (damages) gather in significant quantities at high levels of the stratosphere.

Even the production of CFCs and HCFCs as R-11, R-12, R-113, R114 and R-115 was stopped since 1995 but are still being used widely in existing residential and small commercial air conditioning units and heat pumps. Other refrigerant as R-22 is the most common chiller refrigerants. Dominates in small systems using positive displacement (scroll, reciprocating piston, and screw) compressors, actually R410A is the primary replacement selected for R-22. This substitute offers practically zero ODP. But it increased the GWP by 16 % and lowers the attainable efficiency by 6 %. According (Calm, 2008) R-123 is the most efficient refrigerant for water chillers. However, the need for low GWP option with improved system efficiency still impulse to several investigations.

Other reason was the high energy demand in building sector and increasing energy prices. In this case the sorption technology coupled with renewable sources as solar energy is proving relatively efficient alternatives in terms of energy saving. Sorption technology can be classified either as closed sorption systems or open sorption systems. In closed sorption technology, here are two basic methods: absorption refrigeration and adsorption refrigeration. For open sorption cycles, the basic method is desiccant technology. Sorption-based cooling devices are particularly attractive if the power supply is insufficient or costly, or if thermal energy is easily available, e.g. from solar heat collectors. A summary of the advantages and disadvantages of each technology are present below:

Its ability to operate with low temperature and use any type of heat source; Low operating and conservations costs than the rest of thermally-driven air-conditioning systems; Low noise and vibrations. Simple construction, reliability, long lifetime, with fewer replacement parts are generally bulky, complex and expensive in terms of initial investment. Also some cycles required wet heat-rejection cooling due heat rejection from absorption systems are about 1.75- 2.5 times the cooling capacity. In general this system requires advanced knowledge for maintenance high cut off input temperature for aqua-ammonia absorption chiller, strong solution concentration and generator temperature have the greatest impact on total annual cost can run at a lower temperature. Absence of moving/rotating parts makes them more reliable, low maintenance cost. They do not suffer problem of crystallization and corrosion. It is not so sensitive to the fluctuation in heat source temperature. A small amount of intrinsic electricity consumption is due to the absence of a pump. An adsorption system is simpler to design than an absorption system. Because of fewer individual parts, the cost of production is comparatively lower. Their disadvantages are: The COP and cooling capacities of adsorption systems are still low compared to absorption. This is due to porous adsorbent materials are bad conductors of heat, and the fixed bed operation also leads to poor heat and mass transfer. Leakages and adsorbent deterioration require high vacuum tightness of the container and careful design of external hydraulic circuits due to cyclic temperature variation in the hydraulic circuits. Few suppliers in the market with high cost of commercially available machines are bulky and expensive.

The sensible and latent loads can be controlled separately. Better humidity control, more efficient latent load removal and provide better indoor air quality by controlling the growth of harmful fungi and bacteria. Operate at near atmospheric pressure; the maintenance and construction are simplified and does not utilize condensation to achieve dehumidification and No Chlorofluorocarbons based refrigerant. The electrical energy requirement can be less than 25% that of conventional refrigeration systems but few suppliers in the marked and specially the liquid desiccant systems. The AHU are bulky, the initial investment is higher and is difficult the mounting on existing building. Require pre-cooling and/or post cooling equipment. In hot and humid regions, the effectiveness of desiccant dehumidification would be limited, in this case require higher regenerating temperature in the order of 90oC or a heavier desiccant dehumidifier, to realize an efficient dehumidification and cooling. Compared the desiccant systems drive by solar energy with a conventional AHU the energy consumption is normally higher due the increment of components necessary for the process (dehumidifying wheel, air collectors, and evaporative cooling devices)

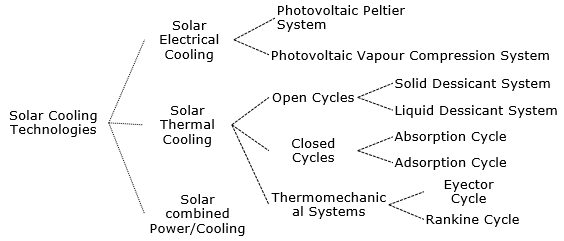

The intrinsic qualities of solar energy make it a beneficial utility, especially for countries located in regions with optimal access to the sun’s rays as tropical zones and as refers before the combine of solar energy whit HVAC technology it’s called solar cooling technology. It can be classified into three categories: solar electrical cooling, solar thermal cooling, and solar combined power and cooling, as illustrated in Fig. 1. Solar cooling technology it been reviewed by several authors Nkweta & Sandercock (2016); Eicker, et al. (2015), and their works are focused on the technologies performance including its technical, environmental and economic aspects.

According the International Energy Agency until 2009, 269 solar-assisted cooling systems have been installed all over the world: 113 large-scale and 156 small-scale. The 92% of these installations are located in Europe. Absorption systems represent 82% of the whole installations and 90% of the small-scale installations, secondly by adsorption systems (11% of the whole installations and 10% of the small ones), the rest by desiccant systems that are only used in large installations.

Solar cooling makes use of hot water produced by solar thermal collectors and or electricity generated from photovoltaic panels. In solar thermal cooling applications it can combine the advantages of the sorption cooling cycles were the working fluids has less environmental impact than the refrigerants used by the VCC systems and at the same time the impact derived from the reduce the electricity used and carbon dioxide produced from the generation.

In other approach, the growing development of photovoltaic (PV) solar systems, the continuous cost reductions in PV technology and the continuous improve of COP, make an attractive solution the use of those systems for drive the VCC cooling systems. The major drawbacks of solar cooling systems are: the complexity of the systems, low efficiency of the main components, high installations cost, the lack of awareness. Those factors determined the lack of proliferation of these but the attractiveness for a future with less fossil fuel consumption and lower CO2 emissions open an important opportunity for these systems.

The typical HVAC configuration has evolved in the last decades in order to achieve better comfort and energy efficient, example: the humidity control in the space is an important task for the HVAC in tropical climate countries. If high relative humidity supply air is supplied will lead to fungus growth in air-tight buildings and affect the health of the occupants. In a conventional AC systems the cooling and the dehumidifying process are in the same unit and at the same time, this lead to low evaporating temperature, a poor COP value for the chiller, and higher energy consumption. Moreover, the fan coil units may become the hot bed of many kinds of mildew due to the existence of condensing water, which will deteriorate indoor air quality.

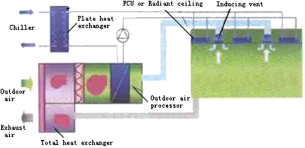

The Independent control of temperature and humidity system (ICTHS), see fig. 2, can realize the independent control of temperature and humidity, and resolve the problems above. For sensible load handling unit, the most typical choice is the radiant cooling system. There two main configurations on the application of the radiant cooling technique: fist the radiant floor cooling is quite suitable for large space buildings, which feature high-intensity solar radiation and high-temperature internal wall surfaces. In typical building, the maximum cooling capacity of the radiant floor is only 30-40 W/m2. The second is the chilled ceiling, is suitable for standard facilities and under favorable conditions the panels can remove 101 W/m2 and the free hanging design can remove 196 W/m2.

For dehumidification system the common choice is multiple, but there are three frequently used types of dehumidification equipment: low- temperature condensation dehumidifiers, solid desiccants, and liquid desiccants above which the most popular in the last years is liquid desiccant. More dehumidification effectiveness at a temperature higher than the air’s dew point to avoid reheating in the system, as well as the possibility of desiccant regeneration at more low temperature than solid desiccant systems.

Today’s, the practice to the increment of humidity due the weather, is to reduce the set-point temperature and then re-condition the air after passing the cooling coil to the proper temperature, which results in a plenty of energy wastefulness. Regarding Huang & Niu (2016), the ICTHS is the best development in the indoor environmental control area for the last 25 years, also refers that it high probability in become in the best HVAC configurations in the future. Besides, the energy potential of for HVAC configurations: a constant volume all air systems, an all-air whit total heat recovery ventilator, a chilled-ceiling with a conventional AHU and finally a chilled ceiling with solid desiccant cooling. The result shows that the benefits of the individuals’ techniques chilled ceiling and dehumidification by desiccant lead to among all configurations; it can save 44 % of primary energy, in comparison with constant volume all air, achieve much thermal comfort and finally be driven by low-grade thermal energy suitable for the use of renewable source.

As an ICTHS practical applications it can found the Dedicate Outdoor Air Systems (DOAS), is a better cooling concept and it is applied in order to achieve a better performance. The reason why DOAS is called ‘‘new concept’’ AC system is that the techniques used in DOAS have widely been applied but are subtly combined to show its broad prospect.

Is quite impossible that all-air can attain its functions especially air ventilation in an energy efficient manner. DOAS is an air-conditioning systems that consist of two parallel systems: a dedicated outdoor air ventilation systems for delivering outdoor air ventilation that handles both the latent and sensible loads of conditioning the ventilation air and a parallel air terminal unit to handle the (mostly sensible heat) loads generated by indoor/process sources and those that pass through the building enclosure. Typical DOAS, shown in fig. 3:

DOAS consist of the following parts: Cold source: could be PTACs, small packaged or split DX units, radiant chilled ceilings, passive chilled beams, or VRF equipment; Outdoor air processor: To ensure that indoor terminal devices run in dry condition, outdoor air heat load, total latent heat load and partial sensible heat load are removed by outdoor air processor; Sensible heat removing terminal devices: could be include cooling ceiling, fan coil units and unitary air conditioner. In the Li & Zhan (2007), study confirm that its can save until 18 % of primary energy if use cooling ceiling in the DOAS configurations. Total heat exchanger: its can use an AHU compose by desiccant wheel and heat recovery wheel for dehumidified outdoor air. Finally, an automatic control system: is necessary for DOAS. The controlled parameters mainly include the outlet water temperature and the cold water flux of outdoor air processor, cold water flux and inlet water temperature of sensible heat removing terminal devices, indoor dry-bulb temperature and dew-point temperature.

DOAS is an all air system without return air, and it eliminates inter crossing infection existing in all air system with return air. The advantages of DOAS among to a conventional all-air are: less noise, lower draft, better thermal comfort and good potential for reductions of the first and operating cost. More benefits likes enhanced indoor environmental quality, increased degree of freedom in the selection of local units. The energy saving exhibits by DOAS it can found in several investigations. When the effectiveness of total heat exchanger is 65%, DOAS using cooling coil as sensible heat removing terminal devices can save the electric energy by 42%, compared with conventional VAV systems. During part-load conditions, with local unit(s) running under reduced capacity mode to fulfill the reduced sensible loads, the DOAS unit continues to supply air at a low enough dew point to maintain acceptable indoor humidity levels. This humidity control benefit is potentially available for almost all DOAS system configurations.

Other important evolution of these advanced configurations of HVAC systems that provide an efficient configuration is the chilled ceiling displacement ventilation (CC/DV). It is a room air distribution strategy; provide high indoor air quality by introducing 100 % fresh supply close to the floor level displacing warm air into exhaust and creating a clean environment zone. Coupling the displacement ventilation and chilled ceiling allows larger load handling capacity and a higher thermal comfort level by reducing vertical temperature difference and draft. Other advantage are the operate temperature of chilled ceiling around 17◦C-19◦C compared with conventional air-conditioning system, which show a great potential on energy and investment saving. Besides, the stratified could achieve a higher indoor thermal comfort level as well as air quality with relatively low energy consumption.

Kanaan, Ghaddar & Ghali (2010), reported that CC/DV systems consumed 53 % less cooling energy than conventional systems but it did not offer energy savings with mixed conventional systems. In order to improve this records Chakroun, Ghaddar & Ghali (2011), developed a model to predict the indoor quality in a typical office in Kuwait conditioned by CC/DV and compared with 100 % fresh air system and with mixed conventional system. The energy consumption was founded to be substantially less when mixing was present. A mixing fraction of 60% fresh air resulted in 37% less measured energy consumption of the system when compared with 100%. The energy consumption analyzed of mixed air system was less by 15-20% from the conventional system.

It can reach better energy efficient if combine DV with demand control. A real study case in two Norwegian schools was published in, Wachenfeldt, Mysen & Schild (2007); the strategy was a CO2-sensor based demand controlled displacement ventilation (DCDV-CO2). During daytime operation, DCDV-CO2 allows the reduction of the required ventilation air volume by 65-75% when compared to Constant air volume. During the daytime the reduction of the total heating energy demand was up to 21%. Concurrently, the amount of unrecovered heat in the exhaust ventilation air was reduced by 54% followed by the lower average airflow rate by 50%. Other innovative techniques developed are combined CC/DV with cooling jackets that are either passively cooled by phase change materials, actively cooled by connecting the cooled jacket to external cooling system, personalized ventilators and personalized evaporative cooler.

Selection of a HVAC system configuration is typically decided in the early stage of the design process when the maximum opportunities for energy efficiency occur. All the technologies have certain technical and economic benefits. Few are better than other for specific application and many alternatives can be used for cooling proposes.

An important point of view is to considering installing an air-conditioning system centralized or individual, but it’s necessary to considerer that centralized systems include a distribution system in the building such as pipes, ducts, tanks, pumps, fans, or exchangers. The efficiency of the overall system depends on the efficiency of all its components, for example an efficient chiller can become an inefficient air conditioner system if parts are poorly connected and badly calibrated. In individual systems, the efficiency often depends alone on the efficiency in the cooling source only.

Operating cost has also an influence in selection procedure, for example the energy consumption for a typical air handling units can achieve up to 20 000 W and a typical desiccant cooling systems can consume up to 55 000 W of electrical. Electrical and economic comparison of four different cooling systems its show in fig. 4. Perez-Lombard, et al. (2011), established a set of low-level requirements in the selection of efficient components: equipment minimum efficiencies, fluid distribution systems, HVAC control ventilation, heat recovery and free-cooling.

Fig. 4 Comparison of cost and power of building heating, ventilation and air-conditioning (HVAC) systems on the log scale.

An overall solution that determines the most convenient system does not exist and the techno-economic viability of a HVAC system depended on many factors such as: Building design, location issues, and utilities: availability and cost, indoor requirements and loads, client issues. Generally, once all objectives were analyzed and identified one or two HVAC systems, a detail qualitative evaluation must have made. A brief report that addresses the following was proposed: the goal; criteria for selection; important factors, including advantages and disadvantages; other goals; security concerns; basic design; HVAC system analysis and selection matrix; system narratives; budget cost and recommendations. Different methods could be used to complete analytical analysis. Simplest as rate each items in qualitative form or more complex as numerical rating. Finally, the highest numerical value obtain will becomes the recommended HVAC systems to accomplish the goal.

Conclusions

In this work the main characteristic of the air conditioning systems was given. It can be concluded from the numerous existing HVAC system configurations that the selection of a suitable system configurations is really complicated at the initial design stage. The evaluation of all available options requires considerable amount of time and efforts. But it’s important considers that savings can achieve if a proper HVAC systems were selected. Hence, it is important to propose an effective and efficient approach according the building requirements.