Introduction

Thermal comfort in buildings is a premise of the modern life. People spend 80-90% of their time indoors, and the indoor environment has important effects on human health and work efficiency.

A report from the International Energy Agency (2018), says that’s actually, it's accounted in the world 1.6 billion of air conditioners (ACs) in buildings. This accounts the 50 % of the total electricity used in buildings around the world or 10% of all global electricity consumption today set by 23 696 TW. According to the report Global energy demand from air conditioners is expected to triple by 2050. In units will grow to 5.6 billion, which amounts to 10 new ACs sold every second for the next 30 years.

HVAC systems comprise on a wide range of different components to define their configuration, is a schematic design that determines the type, number, arrangement of different components and the operational strategy to meet the building comfort requirements. In previous papers, the relevant aspect of the HVAC system relate with category were exposed and the present article explore the activities that involve the design process.

According to Bhagwat, et al. (2015), many savings can achieve if proper HVAC systems were selected. The design is driven by a number of different criteria, such the optimal configuration of the systems, evaluating the energy consumption, indoor air quality, thermal comfort and cost, specifically investment cost, operational and maintenance cost, and environmental cost. Regarding to this the objective of this paper is providing a review the aspect that involves the design process of HVAC systems according to the literature and different methodologies and approaches that assess the design of solar cooling schemes were exposed.

Development

Selecting HVAC systems is a multifaceted process. It’s required a collaborative work between the design engineer and the owner of the project in order to identify and prioritize criteria, consider evaluated different options that meet the project goal and performance as desired. A multidisciplinary approach is better, e.g, if the project has preconstruction service, the design and operator must consult with the construction manager to take advantage of the constructability and considerer value-engineer options. In a first stage the design process most defined aspects as goal criteria and standard requirements. For example, table 1 shows different standards and guidelines that could be consulting by a specialist.

Table 1 - Standards requirement and guidelines examples that assisted the selection of HVAC.

| Standards | Guidelines |

|---|---|

| EE.UU. ASHRAE Standard 55(2010): Thermal Environmental Conditions for Human Occupancy | Chartered Institution of Building Services Engineers, UK (CIBSE) Applications Manual10-2005, Natural Ventilation in Non-Domestic Buildings |

| ISO 7730:2005 Ergonomics of the thermal environment - Analytical determination and interpretation of thermal comfort using the calculation of the PMV and PDD indices and local thermal comfort criteria | Green Guide for Healthcare (GGHC) (2007), Green Guide for Healthcare Version 2.2, |

| ANSI/EE.UU. ASHRAE /IES standard 90.1-2016 for buildings except for low-rise residential buildings. | Enhancements to EE.UU. ASHRAE standard 90.1 prototype building models. Pacific Northwest National Laboratory; 2014. |

| ANSI/EE.UU. ASHRAE Standard 62.1-2016. Ventilation and Acceptable Indoor Air Quality | Air Conditioning Contractors of America (ACCA) Standard 5. HVAC Quality Installation Specification |

| ANSI/EE.UU. ASHRAE Standard 62.2-2016. Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings |

|

| EE.UU. ASHRAE Standard 90.1-2013, Energy Efficient Design of Low-Rise Residential Building | Preventing Moisture and Mold Problems: Design and Construction Guidelines, CH2M HILL, 2003 |

| EE.UU. ASHRAE Standard 188-2015, Legionellosis: Risk management for Building water systems | The International Energy Conservation Code |

| EE.UU. ASHRAE Standard 189.1-2014 Standard for the Design of high-performance Green Buildings | EE.UU. ASHRAE Handbooks |

| Standard 55-2013, Thermal Environmental Conditions for Human Occupancy | Guideline 24-2015, Ventilation and indoor air quality in low-rise residential Building |

| Standard 90.1-2016, Energy Standard for Buildings Except for Low-Rise Residential Buildings | Guideline 10-2016, Interactions Affecting the Achievement of Acceptable Indoor Environments |

| Standard 100-2015, Energy Conservation in Existing Buildings | Heating, ventilation &air conditioning energy efficiency guide for Australian hotels |

| Standard 161-2013, Air Quality within Commercial Aircraft |

After they are specialized, consult all the documents that regulate the technical standards, as well as the comfort requirements in the buildings, the HVAC system to be used is designed. The HVAC system design as a procedure, is defined by two main activities: first, dimension all the elements of the system and second select the optimal design for the case study to which it will be implemented.

For the first activity it is necessary to establish the total capacity of the system that is capable of satisfying the thermal demand of the building, in addition to determining the configuration that it will have, for example: type of system, total elements (chillers, air handling units, systems individual expansion, among others); its spatial distribution and hydraulic arrangement. Finally, the design must be supported through simulation and energy optimization.

In the second activity, it is necessary to consider more than one design proposal of an HVAC system for a building. The final selection of the most appropriate system will depend on the confrontation of several technical and economic criteria. Then the generalities of these two stages will be presented, as well as studies presented by several authors

Sizing procedure of HVAC systems

Selecting the appropriate size of air-conditioning equipment is critical to an efficient HVAC system. Sizing should always be done using a thorough calculation of the maximum space cooling loads and process loads. Loads for space cooling are calculated based on outdoor design conditions, solar loads, estimated cooling loads associated with internal loads from people and equipment, and infiltration and ventilation loads. Once the maximum cooling loads are determined the total size, in tons, can be determined. This step is very significant and affects the capital cost and operational performance of the cooling systems during the lifetime

To ensure this there are several methods: Instantaneous loads, E20 Carrier and CLTD / EE.UU. ASHRAE CLF, Transfer Functions, Thermal Balance and radiant time series (RTS). Currently simulating thermal loads is one of the most widespread resources available for the determination of thermal loads in buildings. It is supported by integrated software package methodologies. These programs can reduce the execution time of tasks and analyze a large number of possible solutions with minimal resources. For these applications on the market, there are a set of packages for thermal simulation of buildings, such as TRNSYS, DOE-2, ENERGY PLUS, COOL PACK, simulator UABC, Trane TRACE, DP-AIR (Polytechnic University of Valencia), Saunier Duval, DeST, among others. Different simulation programs and software’s available for building energy modeling was summary by Harish & Kumar (2016).

As a usual practice among designers is used the compute peak cooling load and multiply with a safety factor as the capacity of the cooling system. This strategy allows accommodate the uncertainties and ensure comfort under all conditions, but the risk of oversized could be important. According to Verhelst, et al. (2017), over-sizing can reduce if others types of safety factor are applied due to improved insulation, improved HVAC controllability and improved awareness of effects on building energy performance.

Other studies contradict that the cooling load obtained from the methods aforementioned are deterministic due the parameters used are constant and don’t take into account the uncertainties that can affect the outcome. Many engineering systems in buildings and their performance are closely associated with outdoor conditions and occupant loads. At present, methods to more accurately determine the cooling capacity through analysis and quantification of uncertainties have been employed by researchers. These analyses are based on several aspects: the typical meteorological day, which groups together a series of extreme meteorological data that rarely concur at the same time.

More sensitive parameters in the final result of the thermal cooling load were stated by Wang, et al. (2016); and Kang (2017). The heat gains derived from the equipment should not be the nominal power, according to manufacturer data; the degeneration of its functionality with respect to the time of use; the uncertainties generated by the composition of building materials and heat transfer phenomena; the possible changing nature of thermal demand over time; the uncertainties derived from the intermittent heat gains depending on the occupation of the building, together with the internal gains associated with the use of the equipment. Also, quantifying redundancy as a type of uncertainty and applying it in the calculation of thermal load is recommended.

Only certain deterministic state is considered by conventional design methods. Otherwise, many more possible scenarios are probabilistically considered by related-to-uncertainties new design methods. But despite these advantages, very little attention has been devoted to this field of knowledge due to high risk level involved, which, becomes unattractive from practical point of view (Yan, Cheng & Cai 2019).

According to the total unit to install, a basic configuration is a is a single cooling unit. This configuration has the advantage of lower initial cost, but when any cooling units fails, the entire system is interrupted, unacceptable for most installations, especially those where the use of these systems is vital. Thermal demand can vary over a wide spectrum in a multiple unit has an appropriate capacity, thus, operation can be alternated and works at maximum capacity and/or efficiency depending on the type of machine and this way, conserves energy.

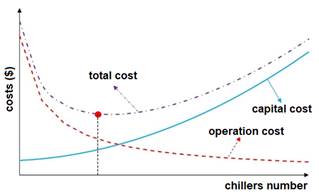

For example, chiller plant is susceptible to work at partial loads, installation of multiple chillers is more common than one. This increase in chillers of equal capacity in a plant benefits the increase in efficiency and the decrease in energy consumption. However, space-related limitations may affect the decision. In addition, plant total cost is another influence factor, see Fig. 1. This may be due to the increase in the rest of the elements that constitute it, for example, pumps, pipes, among others.

To determine the individual capacity that the different units of the system will have, the type of system must be considered. In case of installing direct expansion (DX) systems, the cooling capacity must be in accordance with the thermal zone. These systems are very sensitive to failure if you have not properly calculated the thermal load. In the case of centralized systems, the dilemma lies in installing symmetric or asymmetric units. For example: a plant can be configured in two ways, with symmetric or asymmetric chillers. Symmetrical chiller plant is when all machines have the same nominal capacity. This configuration is the most used in practice, from 50 chiller plants studied, 44 were of symmetrical configuration was reported by Huang, et al. (2018). It has the advantage of ease maintenance because of sharing common elements. On the other hand, its main disadvantage lies in the low plant efficiency while working at partial loads. Asymmetric configuration are different capacity chillers. More system efficient adjustment to load variations is allowed to achieve with this configuration and it can represent a saving potential.

At present, load distribution between chillers is carried out through recommendations, resulting very limited this field of study. For example, use of symmetric chillers, is recommended by EE.UU. ASHRAE 90.1-2013 standard (American Society of Heating, Refrigerating and Air-Conditioning Engineers, 2013). Similar statement is made by Cuban Standard NC 220-3:2009 (Cuba. Oficina Nacional de Normalización, 2009).

Finally, the hydraulic arrangement only concerns all-water and air-water centralized systems. A chiller plant can be configured in three different ways: series, parallel or mixed chillers. A hybrid or mixed configuration is when a series of chillers are configured in series, while operating in parallel with another arrangement of chillers also configured in series. Although there is no general criterion about which provision is the best to use (since there are different design, exploitation and external factors that determine the advantages and disadvantages of each interconnection form). However, most plants are interconnected in parallel (Kapoor & Edgar 2015).

Optimization procedures for designing process

HVAC design optimization problems can be classified into two types. The first type is optimization of static design parameters as building envelopes, HVAC system and components, ductwork and hydraulic systems and the second type is optimization of the dynamic input variables, which usually comprise control scheduling and set points. Optimize an HVAC component it requires the evaluation of different system alternatives at the initial design stage by modeling, simulation, and optimization techniques.

For example Reda, et al. (2016), optimized based on a computer simulation the design variables: solar collector area, the volume of the hot storage tank, the volume of the cold storage tank, and thermostat set point of the auxiliary heating element of a small scale solar assisted, silica gel-water, adsorption cooling system. The decision support approach provided by the authors was: Optimized different configuration based on the energy performance. The design parameters for varying were: slope of the solar collectors, solar collector area, the volume of the hot storage tank, the volume of the cold storage tank, and thermostat set point of the auxiliary heater. Finally evaluated the economic and environmental benefits of the optimized solutions based on Present Net Value Method. Select the final optimized solution with the lowest solar saving. Other study was presented by Wang, et al. (2016), with the optimization of a Hybrid combined cooling, heating, and power systems (solar energy and natural gas). The optimization objective was set the capacity configurations variables: solar installation ratio, battery size, heat storage tank. The fitness function of the optimization problems was based on maximize energy efficiency and minimize economic cost. The intelligent tools that were used was Demand-supply matching method by a Genetic algorithm.

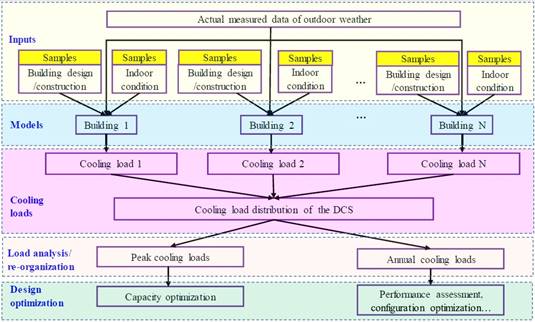

Gang, et al. (2016), refers that studies on the optimized design of District Cooling System (DCS) are very limited, in their papers the application of the uncertainty-based design optimization method was examined in several aspects: the performance assessment, system sizing, configuration selection and technology integration. In the particular case of systems sizing the capacity of the DCS was determined at different risk levels. Based on the annual cooling load distribution, the performance distribution of the DCS with different configurations and technologies were obtained. The optimized DCS was determined by balancing the risk and benefit. In fig. 2 the Steps to implement the uncertainty-based design optimization method are illustrated.

It is emphasized that to obtain a robust result in the solution of an optimization problem, it is necessary to use artificial intelligence tools. The optimization of an HVAC system is a nonlinear combinatorial mathematical problem, restricted with continuous and discrete variables, and as such, it is a challenge for standard optimization methods.

Selection methodologies examples. Process of selecting alternatives of an HVAC system. Examples of methodologies used

Selection of HVAC system configuration is typically decided in the early stage of the design process when the maximum opportunities for energy efficiency occur. All the technologies have certain technical and economic benefits. Few are better than other for a specific application and many alternatives can be used for cooling proposes. Generally, once all objectives were analyzed and identified one or two HVAC systems, a detail qualitative evaluation must make. A brief report that addresses the following was proposed: the goal; criteria for selection; important factors, including advantages and disadvantages; other goals; security concerns; basic design; HVAC system analysis and selection matrix; system narratives; budget cost and recommendations. Different methods could be used to complete analytical analysis. Simplest as rate each item in qualitative form or more complex as a numerical rating. Finally, the highest numerical value obtained will become the recommended HVAC systems to accomplish the goal. Different investigations and design methodologies are presented:

Wang (2000), exposed more details requirements to take into account during the selection of the air-conditioning systems. That was:

Applications and Building Occupancies. This is due to the air conditioning systems are used for different applications or building occupancies they need different design criteria, operating hours and different systems characteristics.

System capacity. Is usually that the system’s capacity closely related to the selection of HVAC systems.

Indoor Air Quality. Depends mainly on the minimum ventilation control according to to the requirements of the facility in question.

Zone thermal control and sound problem. Comprises the accuracy of control and control mode that could provide each air conditioning systems. The author suggests that sound problems often are the result of improperly designed systems and poor selected fans.

Energy efficiency. Each type of air conditioning system has its own efficiency and energy use intensity as shown in table 2, 3and 5 of the present article. It’s necessary to estimate the combined effect of the whole systems which include the primary and secondary loop, or other components. Also considered the energy conservation measures such as economizer, heat recovery devices, variable speed drivers, occupancy sensor, thermal store etc.

Fire safety and Smoke control.

Space limitations. The design engineer seldom has sufficient information to render the optimum HVAC design for the project, and its space requirements are often based on a percentage of total area or another experiential rule of thumb. The final design is usually a compromise between what the engineer recommends and what the architect can accommodate.

Maintenance. A rule of thumb is that 20% of the cost of the building is in the first cost, with the other 80% being an operation, maintenance, and renewal of the building and building systems over the life cycle.

Initial and operating cost. Generally, the more complex systems become and the more features it has, the higher will be the initial cost.

As a practical application, Augelis & Papadopoulos (2009), applied a multi-criteria analysis for design an HVAC system which goal is implemented an HVAC system that can transform to use of raw materials and energy consumption. Authors based their criteria of selecting and comparing different options in four main categories or fields: economic criterion, energy criterion, user’s satisfaction criterion (IAQ and thermal comfort) and environmental criterion. The economic criterion was analyzed by the feasibility of the investment using the net present value (NPV) method. The energy criterion was described by the annual specific energy consumption. The thermal comforts by the mean hourly operate temperature and the IAQ was determined by the carbon dioxide concentration per hour and user. Finally, the environmental criterion was considered by the greenhouse emissions produced by the construction and operation of the HVAC systems during its lifetime.

For the selection method of different options, authors used weightiness factors and indifference, preference and veto limits. Those were formulating subjectively according to the goal and the decision-makers preferences. The methodology proposed was the following steps:

Modeled the HVAC systems using simulation tools in order to obtain: estimate indoor climate for the evaluation the thermal comfort and IAQ, energy consumption value that used as input for energy cost analysis.

Sizing and configuration different HAVC system.

Using the multi-criteria method Electre III for multi-objective optimization were as a result of then rank all the alternative under three economics scenarios.

In this study case, the options were presented more feasibility value was the selection. However, they appointed that the application of a multi-criteria analysis with a large number of criteria may unnecessarily complicate both the solving process and the conclusions drawn.

In other papers Arroyo, et al. (2016), employ the choosing by advantages (CBA) method for selecting an HVAC system for a Net Zero Energy (NZE) Building. According to them the CBA method is superior to the multi-criteria decision making method as the analytical hierarchy process and weighting, rating and calculating process, due its ability to provide transparency, support consensus building and allow for continuous improvement. The researchers confirm also that the decision process can be categorized as an iterative process. The main characteristic of the CBA method was: the decision was only based on the advantages, this are rather than the classic advantages and disadvantages. The advantages most weights based on the importance, through criteria, factors or other type of data. Cost is a constraint not a value so, it cannot mix with factors that are used to gauge a value. As a final point was suggested other authors the CBA method most applicable by a design team compose mainly by specialist of different areas, an example, in the case study analyzed in the paper the team was compose by: the owner, architect, contractor, mechanical engineer, lighting design, electrical design historical architect and structural engineer.

In order to include solar cooling technologies as an option for HVAC selections choices, researchers published different methodologies for assessing those advances HVAC schemes. Tsoutsos, et al. (2010), proposed the following steps for evaluating and optimizing an absorption solar cooling plant:

Study the maximum, minimum and average heating and cooling demands of the building for determining the technical characteristics of the systems.

Selection of the solar cooling technology to be applied.

Sizing study.

Carry out studies on an optimized solution for the solar fractions by varying the technical characteristics that mainly concern to the principally plant elements.

Economical evaluation of optimized solutions and optimization of systems and finally remarks

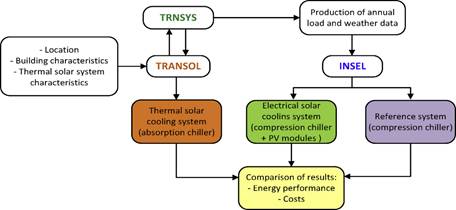

For compare and select the best energetic and economic choice between solar thermal cooling systems to compose by an absorption chiller and electrical chiller assess by photovoltaic arrays, Eicker, et al. (2015), proposed a methodology for evaluating by computational tools as can see in fig. 3. The computational programs for energy simulation procedure used was: TRANSOL to the design and predict the solar thermal installation and INSEL to simulate the solar irradiation, photovoltaic modules, and the electrical chillers and finally TRNSYS for load calculation

An interest consideration was made by the author for improved the design of both schemes: The backup system of photovoltaic cooling systems was considered the public grid. The backup systems of the absorption cooling systems (ACS) was considered an electrical chiller. In the ACS schemes were included the Domestic Hot Water and space heating for accounted additional energy savings. In both systems was including a cooling storage tank.

A critical step in all methodologies exposed before was sized and modeled the thermal or photovoltaic solar collector surface, due is the main drive source of the systems. The energy provides by they can determine the capacity of the air conditioning systems and the technologies used and their efficient have a strong influence on the hole systems. The solar penetration ratio should be selected carefully such to take advantage of the efficient use of solar energy and not to exceed the maximum allowable area for installing the solar collectors. A design procedure to determine the appropriate sizes of the water heating system components e.g.: collector effective area, hot water storage tank size and minimum auxiliary heat supply rate.

Collector area has a significant influence on the performance and economic feasibility of a solar cooling system. If huge cooling demand should be satisfied by solar cooling systems, large dimensioned of the component it’s required, causing higher operational cost. Furthermore, the larger cooling demand causes more running hours of the other equipment such as pumps etc, and more investment cost. The non-continuous aspect of solar energy can cause an interruption in the cold supply during nights; in this case, a thermal storage tank is a perfect design option. In case of solar cooling installations, the recommended ratio between storage tank volume (V) and collector field area (Ac) is 0.05m ≤ (V/Ac) ≤ 0.18 m, according to Rodríguez-Hidalgo, et a.l (2012). In the design of storage units the main points for taking into account are

Be compatible with all the other units in the plant.

Confirmed to the overall operational strategy of the plant like operational temperature range, number of hours of storage required, charging and discharging rate, integration with solar collection system etc. It should be ensured its long-term stability, i.e. the number of cycles that both container and storage medium can withstand without degradation of their properties.

The long-term stability of the system can be compromised by two factors, poor stability of the properties of materials under extensive thermal cycling and/or corrosion and chemical incompatibility between the PCM and its container.

Accordingly, the best-suited storage material, heat exchanger between the thermal storage material and heat transfer fluid (HTF) etc. should be chosen.

Choosing the best solution, it’s also a difficult task. It’s been observed in literature a high heterogeneity in comparative study cases, explained by the variability of the system design, its operating conditions and the mathematical models used in the case of simulation studies. In general approach the correct answer just depends on a deep study, the establishment of standard performance indicators as the efficiency, the technical maturity, the economic feasibility, the environmental impact, the most advantageous climatologically conditions and the design parameters.

Conclusions

Selecting the appropriate size of air-conditioning equipment is critical to an efficient air conditioned system and affects the capital cost and operational performance of the cooling systems during the lifetime. Sizing should always be done using a thorough calculation of the maximum space cooling loads and process loads, however, besides the deterministic method that usually employs the designer engineers, different studies were exposed that take into account the uncertainties derived from outdoor conditions and occupant loads. Also for the more accurate outcome, optimization studies that involve the design process were presented.

When one or two Air Conditioned systems were identified as an optimal option, a detail qualitative evaluation must make. Different methods could be used to complete analytical analysis. Simplest as rate each item in qualitative form or more complex as a numerical rating. Finally, the highest numerical value obtained will become the recommended HVAC systems to accomplish the goal. Different investigations and design methodologies expose in literature were presented

In view of rising energy demands in HVAC sector, various alternative and innovative systems gained increased consideration due to their low energy requirements and environmental implications as the solar cooling systems. Different methodologies described in papers were provided. Especial attention must make to the select of the main components as solar collector array and thermal storage. Finally, successfully solar cooling installations were presented.