Mi SciELO

Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Centro Azúcar

versión impresa ISSN 0253-5777versión On-line ISSN 2223-4861

cen. az. vol.43 no.4 Santa Clara oct.-dic. 2016

ARTICULO

Initialcapacity of bioenergetic production for the recycling of plastics in cabinda,angola

Capacidad inicial de producción de bioenergéticos para el reciclado de plásticos en cabinda, angola

David Muto Lubota1*,Tania Grancho Freitas1, Divanize de Jesus Sambovo Landa1,Juan Esteban Miño Valdés2and Binko Mamade Toure3

1 Universidad"11 de Noviembre" Cabinda, Angola.

2 Facultadde Ingeniería. Universidad Nacional de Misiones. Calle Rosas Nº325. CP 3360 Oberá,Misiones, Posadas, Argentina.

3 Universidad de N'Zerekoré, Republic of Guinea.

ABSTRACT

In this paper, the study of thepossibilities of the efficient use of forest residuals as raw materials, forthe production of bioenergetics that guarantees the operations of a plant for therecycling of plastic residuals is exposed. In the study, a conceptual model andthe procedures for the assimilation of technologies of bioenergeticproduction, reported in previous works, is validated (Muto et al., 2016). Dueto their significance, it is considered the uncertainty to the future changeswith emphasis to the growth of the demand of capacities of prosecution of urbansolid wastes (USW) and the readiness of the raw material. Suitable values of initial investment capabilities are determined fora first step forward so that a second stage investor that increasescapabilities must be run at 6 years for initial investment executedcapabilities. The first investment will recover in 2.8 years.

Key words: bioenergetics, initial investments, technologyassimilation, uncertainty, plastic.

RESUMEN

En el presente trabajo, se expone el estudio de lasposibilidades de que mediante el aprovechamiento eficiente de los residuosforestales como materia prima, para producción de bioenergéticosque garantice las operaciones de una planta de reciclaje de residuos deplásticos. En el estudio se valida un modelo conceptual y los procedimientospara la asimilación de tecnologías de producción de bioenergéticosreportados en trabajos anteriores (Muto et al., 2016). Por su importancia seconsidera la incertidumbre a los cambios futuros con énfasis al crecimiento dela demanda de capacidades de procesamiento de residuos sólidos urbanos (RSU) ya la disponibilidad de la materia prima. Valores adecuados de capacidadesinversionistas iníciales se determinan para una primera etapa con visión de queuna segunda etapa inversionista para incrementar capacidades se debe ejecutar alos 6 años de ejecutada la inversión para capacidades iniciales. La primerainversión se recupera a los 2,8 años.

Palabras claves: bioenergéticos, inversiones iníciales, asimilación de tecnologías,incertidumbre, plásticos.

INTRODUCTION

Undoubtedly there is a need to enhance the energymatrix with renewable energy sources to which new technologies will berequired, so that in studying alternative assimilation of technologies forrecycling of Urban Solid Waste (USW), which will require increasingly energycarriers, it is necessary to study the potential use of bioenergy for theseprocesses of recycling of USW.

It is a feature of the process of recycling of USWthat each waste has specific technologies that differently requires some formof energy. So, for example, the recycling process of paper requires electricityand steam due to the characteristics of the industrial processes, González(1982). The plastic recycling requires energy in the form of electricity, Grancho (2015) and aluminum requires the energy in the formof direct heat for melting Sambovo, (2015).Therefore, for energy assurance, through bioenergetics of each type of USW, aspecific study is required, that considers the technology and logistics toensure a stable supply of energy sources to the industrial process in which itis invested.

One aspect of great importance, it is also, that to bethe source of supply of biomass energy will be a problem of uncertainty in theavailability of biomass for attaining bioenergeticproductions. In addition, this is combined with uncertainty regarding thedemand for recycling capacity, so as it is known, the development itselfimplies that it increases, due to growth in consumption habits, the totalvolumes of USW and within them each of the types of waste. These problems ofuncertainty lead to that the investors' processes must evaluate the alternativeof investing in productive capacities in excess with reference to the firstyears of operation, in order to achieve the necessary production capacity whenproduction capacity increases by increased levels of the different componentsof the USW. Rudd and Watson (1968) raised this problem and later it wasconsidered in the existing problem in the availability of biomass when used asraw material (Oquendo et al., 2016). The applicationof these concepts have been included in a specific procedure for the study ofthe supply chain (Muto et al., 2016) which determines the initial investorability to solve the problem of recycling of USW and energy insurance.

In the specific case of plastic recycling, under thecurrent conditions of Cabinda, it is needed to determine the capabilities toinstall for the production of electricity.

MATERIALS Y METHODS

For the execution of this work, a conceptual model andappropriate procedures for the assimilation of technologies substantiated tothe effect was employed (Muto et al., 2016). In the context of a country of theso- called third world, regarding the cost, time used and functionaloperations, for whose implementation requires a set of actions to process allthe information and solve problems arising from the uncertainty of technology(Ley, 2006).

The application of procedures have had asmethodological axis the establishment of the different elements that affectdecision-making, including the national demand perspective, the priceforecasts, the balance of demand and capacity per year, the technology study,consumption of raw materials and sources of supply, investment costs, annualproduction cost, size and location of the plant. It has been an essentialaspect in the consideration of uncertainty to future changes, (Rudd and Watson,1968).

RESULTS AND DISCUSSION

According to the procedure followed, presented andbased on (Muto et al., 2016), we follow the next steps:

3.1. Step 1. Determination of product demands and rawmaterials availability.

In Table 1, the demand for plastic processing existingamong Cabinda's USW is presented.

Table 2 shows the demand for electricity to processthis plastic in urban solid waste (USW).

In Table 3, the demand for raw materials for theproduction of bioenergetic according to theconversion factors for forest biomass is presented.

3.1.1. Availability of raw materials

Quantification and characterization of biomass energythat exists around a given location is the starting point for any project usingbiomass as raw material. In this study, aside from knowing the different typesof biomass energy, production systems associated with biomass energy arecharacterized by the diversity of exploitable resources. Undoubtedly, thissignificantly increases the complexity of the analysis because each projectrequires specific studies (availability, extraction, transportation anddistribution) to determine their viability.

The residual biomass, which can be used for energypurposes, is characterized by its diversity in terms of their origin andcharacteristics. Therefore, when making territorial studies, this diversity isa very large number of possible alternatives in terms of availability,extraction, logistics and biomass consumption, which significantly increasesthe complexity of them. This complexity is associated with a high degree ofuncertainty due to the multiple uses and interactions between each other andthe biomass market itself. That is, depending on the evolution of prices willbe more or less profitable to extract biomass from the forest. A first approachto the territory reveals that the main sources of biomass in the province of Cabindaare the forests and agricultural crops. On the one hand, the province ofCabinda has the most productive forest ecosystems throughout Angola because ofits orographic layout and weather.

However, despite this potential availability, thereality is that most of this material is immobilized and available in theforest. The absence of technical instruments of forest management, thefragmented structure of the property, the difficult accessibility of land foruse or the characteristics of biomasic resource(impurities, moisture, heterogeneity) that have hampered mobilization of forestresources.

3.1.2. Growth dynamics of the forest

According to the Institute of Managementof Public Forests (IDF, 2013), Maiombe's forest withits 300.000 hectares approximately, grows an average of 4x106 tonsyearly in natural biomass or its equivalent to 4.400.000 m3 yearly.However, the biomass considered useful for wood production in market value,that is, taking out the natural biomass, is the corresponding part to thosespecies whose utilization is unknown yet and the forest exploring wastes(branches, defective wood, stocks, etc) isapproximately 1x10 Kg/ yearly, equivalent to 100.000 m³ of wood. The forestgrowth rate is 0.3 m3/ hectares yearly for the type I forest and forthe type X forest is 0,5 m3/ha/ yearly.

Wastes generated in the forest can reach values of 30to 35% of the volume of wood for industrial purposes and this value, 5% of thevolume is intended for traditional energy purposes. In terms of volume, weobtain values of 494 m3/ha with 369 trees and 442.2 m3/hawith 365 trees, which leads us to consider that the forest is highlyproductive.

Forest wastes are wood, charcoal, sawdust, twigs andleaves from the tree pruning. Such waste have features 100% natural, they havehigh density of charring fire, it is a solid organic material, and easilyabsorbs water (Muto et al., 2014). Although the volume of waste generated inagricultural production is very high (hundreds of millions of tons annually) arelatively small part would be profitable today to power because of the lack ofappropriate technology/costs of collection and transport. There are, however,several studies analyzing the potential of many agricultural residues for theproduction of biofuels, considering aspects of logistics and current use (ifthey are already normally removed from the field (Muto et al., 2016).

For energy production, forest resources can beutilized, i.e. biomass from forestry practices of cleaning, sanitary pruningand the remains of wood that can be used, branches and bark, tops and stumps orroots. Forest residues have the advantage of constant availability. Thisproperty makes biomass renewable energy easier to manage, allowing us to createa reserve of energy for times when other sources are not available.

Table 5 shows the amounts of forest biomass by thezones of location and distance from the town of Cabinda where necessarily willbe located the plant of plastic recycling and the processing facility fromforest waste to electric power, by development strategy defined by thegovernment of Cabinda. In Table 6, the distances between the different areasare presented.

3.2. Step 2: Surveillance onavailable and emerging technologies.

Interior and exterior relevant informationon technological trends is periodically monitored.

The current socioeconomic scenario is marked by theglobalization of markets, mainly caused by the substantial improvement ofcommunications and transport, in which has greatly influenced the developmentof Information Technology and Communications (ITC) allowing the exchange ofknowledge at any time globally.

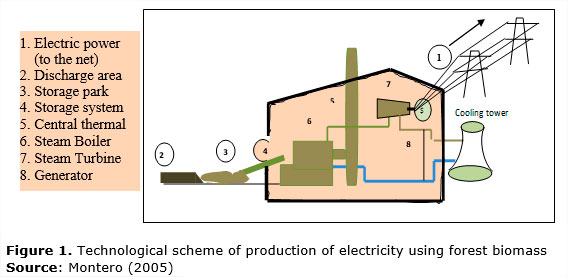

In the case study, it was consulted a variety ofdetected sources which shows that the types of documents to monitor is verybroad: from scientific and technological information (Patents, scientificarticles, standards, etc.) to information relating to news, events, courses,supply and demand for technology, research projects, also carried out semi-automatically.According to this search, it was selected the technology proposed in Figure 1.

The main equipment used forcombustion of forest residual biomass are steam boiler and the steam turbine(e.g. of a small plant).

A description of the equipmentfor direct combustion of biomass is done:

· Steam boiler: biomass is burned directly to obtain hot gases andthermal energy generation (by exchanging heat of the combustion gases withwater), and / or electricity (superheating the water until steam).

· Steam Turbine: drivenby pressurized steam and its rotor are moved and transmit the rotation to thegenerator.

· Generator: itsrotor as move generates electricity.

· Cooling tower: Inladen, it cools the water for steam condensation.

Therefore, according to thedesired application of combustion and magnitude in energy efficiency (power ofthe system of energy generation), there are various scales by which technologydiverges in configuration and magnitude. For the analysis of combustiontechnology, they have distinguished three scales according to the installedpower.

· Small-scale (5-500 kW): Rangingfrom domestic homes up to boilers to supply hot water or heat to residentialand community levels.

· Medium scale (500 kW 5 MW):Includes boilers for residential supply, buildings and / or small districts,depending on the installed power. The energy produced is thermally and / orelectrically, depending on the equipment installed. For higher powers 1MW,there are usually installed gas turbines or steam for electricity generation.The supply of biomass from forests involves a regional scope.

· Large-scale (> 5MW): Theseare plants aimed at generating electricity, which can supply thermal energy tocover the heat demand of the territory (hotels, restaurants, industrialestates).

3.3. Step 3: Alternativediagnosis of the availability of raw material

This is another step that isrecommended when the raw material is insufficient or is not compatible withexisting technologies in the market, which is not the case.

3.4. Step 4.Scaling technology

In this step, dueto their specialized nature we seek alliances with third parties and in thiscase in particular with universities or research centers.

In the same, wecreate a group of specialists responsible for the development, design,selection and making of the assembly of the power plant, according to the typeof raw material and the materials to produce.

Requirements shouldbe taken into account such as operational flexibility and productive capacity.The technology decides which design should contribute to lower costs forproduction, so these plants should be well conceived from the beginning inorder to prevent pollution and generation of carbon dioxide.

3.5. Step 5: Planning ofalternatives of chain supply

The procedure developed forthis step includes as a first requirement the planning of the logistics supplyof raw materials that has been recommended in previous work (Muto et al.,2016).

The actual behavior for thiscase study outlined below:

The situation corresponding to the majority ofexisting farms today is that the remains extended are scattered over the plot.One aspect of crucial importance in optimizing the collection of the remains isthe integration of operations of this residual biomass concentration in theconventional use of forestry. Once the material is concentrated, the majorlimitation affecting the handling of residual forest biomass is the low bulkdensity, difficult and expensive transport. Therefore, harvesting technologiesare based either on trituration in compression chips or waste to form high-densityunits. Regardless of the methods used for timber extraction biomass, there arecurrently three technology options for extracting forest residues. Thelogistics system includes the collection, transport, storage, handling andpretreatment of biomass energy, i.e. all activities between the points oforigin of the plant biomass to generate electricity.

The logistics system is in thecase study, because there is a variety of types of energy biomass with verydiverse backgrounds, the accessibility of biomass will be different dependingon the topography and infrastructure of the site and the features that mustsupply. Thus, it can be a direct route from the mountain or field to the plantthat includes the collection, pre-treatment, storage, and transshipment incertain possible points. A description of each of the stages is the following:

3.5.1. Stage 1: Cutting and extraction zone

Cutting and extraction: the first phase will takeplace in the forest or on the mountain and involve the cutting and extraction.By cutting, it means forest or agricultural operation where the wood or plantis obtained and the residue is generated, after the cuts will proceed to theextraction or removal of material to accessible places for the teams that madethe crushing. For operations related to extraction, mobile machinery must beadapted to the specific conditions of each type of crop or specific use andthere are usually: a) tractors with the respective attachment; b) Hydraulic Sarmentador of one or two boxes; c) Autoloaders; d) packingmachines.

The packing of waste, both agricultural and forest isa very suitable solution to reduce transport costs, preserving thecharacteristics of biomass and ease its storage. It is considered waste biomassin the form of trunks, branches, stumps, sprouts and sanitary cuts, which havealready been killed, processed and debarked in mount, manually or mechanized,moving to short distance. The case study should combine the two systems, manualtransports and autoloaders, due to remote access areas; we can also useshort-distance transport that allows accumulating the raw material at a pointeasily accessible.

3.5.2. Stage 2: Biomass Logistic Centre (BLC)

Forest biomass, by its very nature, requires a numberof modifications on the raw material with specific machinery so that it meetsthe requirements of the equipment of the power plant:

· Particle size reduction: is thehomogenization and size reduction of biomass energy, use systems chipping,grinding, milling, screening and disintegration.

· Moisture reduction: primarilyto reduce transport costs, is achieved by drying. It is the most expensivestage of the previous transformations. There are two forms of drying, thenatural and the forced drying.

· Densification or compaction: isto reduce the volume of biomass energy, achieving to minimize the cost oftransportation and storage. At the same time degradation by fermentation, isavoided. There are several alternatives such as pelletizing, briquetting andpacking.

· Removing unwanted components: is to remove foreign debris,such as metals, plastics, stones. Screening techniques, gravity separation andmagnets are applied.

· Storage: taking into accountthe type of vegetation of Cabinda and characteristics of the raw material is tobe used covered warehouses and establish mechanisms for effective monitoring tominimize any risk.

3.5.3. Step 3: Power Plant

After the discharge of the materials with energytarget in the central warehouse of the power plant, a prior natural drying tothe residue is performed, in order to reduce its moisture content and increasethe calorific value, it proceeds the management and weighing battery.

3.5.3.1. Transport

Short distance transportation of solid waste from themountain to the logistics center is done by: Dingo Autoloader AD6A-24

The long-distance transportation to the center is doneby using a rigid trailer truck, road train (rigid truck with trailer) or mobilefloor truck mainly used only for the transport of crushing solid waste.

3.5.4. Step 4. Determination of the optimal initialcapacity of the plant considering the uncertainty of future changes:

Based on the experience in previous studies, Rudd-Watson (1968) and similar works for the industry of sugar cane developed by (Oquendo and González, 2005), has proposed a procedure shownin (Muto et al., 2016).

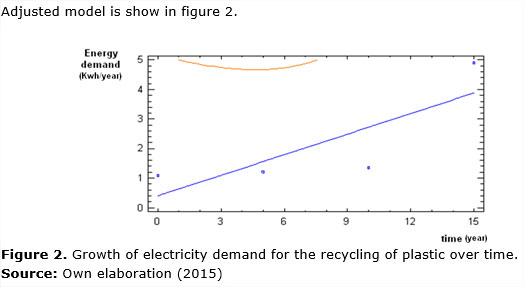

This procedure includes twostages; one to study the uncertainty in the demand of the installationproduction and another for the uncertainty in the availability of raw materialsfor biofuels. The necessary growth in electricity production has been estimatedbased on the amounts of plastic to recycle as summarized in Table 2 byconsidering future changes in Table 1.

The first step of the methodincludes adjusting an equation of growth in demand for bio-energy and rawmaterial availability Figure 2.

3.5.5. Electricitydemand

Simple regression -Energy demand vs. Time

Adjustedmodel is show in figure 2.

Were:

b1 =Slope

i = interest rate financier (%)

bo = Coefficient of the equation of the curve

C*i = Optimal initial capacity (kg/day)

q = time to carry out the first expansion (year)

C* = Capacity tocarry out the expansion (kg/day)

Ct = Total Capacity(kg/day)

From thisinformation and applying the methodology proposed in step 5 of the procedurefor determing the ability of initial investment, alsoconsidering financial uncertainty (Muto et al., 2016) the results forelectricity demand obtained are expressed in Tables 7 and 8. In the case ofelectricity, when it also includes the time performing the first extension.

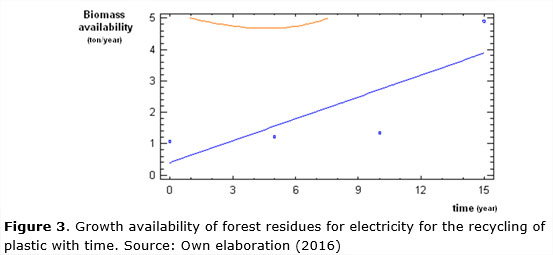

3.5.6. Biomass Availability

The mathematical expression of the relationship ofbiomass availability with time is expressed as follows:

Table 9 summarizesthe results of the analysis, it is concluded that the limit of the ability ofinitial and subsequent investment is given by the actual power demand forplastic recycling since there is full availability of forest residues.

The results of Table 9 allow us to understand that the limiting aspect for initial investors'values is the demand of electricity for plastic recycling since there is alarge surplus of forest biomass in relation to the demand that is set to ensureenergy resources required for this action. Consistent with these results weproceeded to estimate the investor heats of facilities and other economicindicators when the plant is producing at full capacity in the sixth year.

3.6. Step 5. Optimizing transportation costsof forest biomass for processing USW of Plastics

To determine transportation costs of forest biomass tothe plant of power generation considering the different sources of rawmaterials the problem of minimizing transportation costs is formulated as follows:

Decision variables

Bi - Binary variable indicating whether aprocessing plant is installed at the location i. i = 1… n

Xij - Number of tons of forest biomass to transport betweenlocations i and j. i= 1 … n,j = 1… n

Parameters

Li - Involved locations. Collection centers of forestbiomass and other possible locations to install the processing center. i = 1… n

Pi - Production of forest biomass in each location. i = 1… n

LDj - Subset of locations where forest biomass isconsumed.

![]()

Dij - Distance between locations iand j. i = 1 … n,j = 1…n

Dj - Demand for forest biomass in each location. j = 1 … m

Cpalm - Cost of transporting a ton of forest biomassdistance of one kilometer

![]() - Function that indicates how an amount offorest biomass is converted

- Function that indicates how an amount offorest biomass is converted

into electrical energy.

Objective function

Restrictions

In one location you can install a processing plant,but this is not mandatory, this is expressed by the binary variable Bi:

To limit the total number of processing plants, youmust add a restriction:

The following restriction assures that each locationwhere forest biomass occurs can only send a maximum amount of forest biomass:

Every place where electricity is consumed must receivea minimum amount of biomass for processing and conversion:

Due to the large availability of forest biomass thesolution of the problem of transportation is simplified, since the decision istransport residual forest biomass available from the zones, 4 of Cabinda, 3 of Cacongo that are the closest and the necessary rest of theZone 2 Buco –Zau.

For these conditions, the minimum cost oftransportation, to meet the demand that causes the determined initialinvestment is 4 727.51 USD / year.

3.7. Step 6. Technical, economic and environmentalassessment of new technology

To analyze the costs of investment and productioncosts in line with the proposed methodology and the information available by(Peters and Timmerhauss, 1981) were determined andupdated by the current cost index year 2016 forecast as it recommended in thescientific literature (González et al., 2012).

Once the fundamental plant equipmentis sized, economic analysis was made, on the basis of calculating theinvestment cost, production cost, and profit and profitability indicators.

3.8. Determination of the total investment cost andannual output of the processing plant from palm oil into biodiesel

3.8.1.Determination of investment costs

The basic investment studies were referenced to thestudy by Grancho (2015), accordingly for aninstallation capacity of 108,000 KWh per year being the results of estimatedcosts of equipment of 20 191 USD, which along with raw material inputs, allowsfor a production capacity of 237 268.88 KWh estimate the value of equipment costsand the total cost of the investment with the help of recommendations of(Peters and Timmerhauss, 1981).

Being:

CIcpn : Fixedinvested Capital of the new capacity ($)

CIcpnt : FixedInvested Capital of the reference capacity ($)

cpn : NewCapacity (kg/d)

cpt : ReferenceCapacity (kg/d)

Being; CFI = 124 979.47+ 0.05 CFI,then:

CFI = 124 979.47/0.95 = 131 557.33 USD

For the determination of the totalproduction costs it is necessary to consider all inputs of raw materials andadd the transportation costs of Forest Solid Wastes to Power Generation Plantadjacent to the Plastic Recycling Plant.

Adding the minimum cost ofTransportation the CTMP is: 4 727.51 USD / year for the production of Energy offorest residues.

C. MP = 527 264.2 + CT = 527 264.2 +4 727.51 = 531 991.71 USD / year

Estimates of Total Costs of AnnualProduction should be made for different production capacities to be achieved inthe years of operation of the facility, which will gradually grow as theinstalled capacity of electricity generation is demanded by the demandprocessing plastic residues.

For the determination of these TotalAnnual Production costs were selected the percentages of capacity utilizationachieved with the different possibilities of electricity demand. Table 11 presents the results of the costs of power generation capacities for 100percent utilization of the installed capacity of power generation.

CTP – 0.414 CTP = 574 826.74 = 0.586CTP

CTP =574 826.74 /0.586 = 980 933.USD/year

Cost-effectiveness studies require to determine theeconomic conditions in the first 10 years of production in which necessarilythere have to be a period of under-utilization of installed capacity due to thelack of plastics raw material recycled in the USW which will be covered graduallyin the first 5 years. According to this, production levels and annual cost willbe as reflected in Table 12.

3.9. Step 7. Incorporation of technology

In this step, according to the results of the economicindicators of the investment proposal is adequate the formal proposal for adraft of implementation of a plant for recycling plastics and electrical energyrequired for this process using for this forest biomass.

CONCLUSIONS

1. The application of a specificprocedure is feasible to plan the initial size of an Electric productionfacility of Forest Biomass in the supply chain process of conversion of biomassinto energy carriers.

2. The costs of transportation of forestbiomass in the conditions envisaged do not affect the economic feasibility ofthe project.

3. The initial capacity to be installedto convert forest biomass into electrical energy is not limited by theavailability of the raw material, but by the needs of recycling plastics sothat future actions should be made to remove that restriction and increase thepossibilities for recycling of plastics through appropriate collection andstorage of this urban solid waste.

4. The initial capacity to be installedto convert forest biomass into electrical energy is not limited by theavailability of the raw material, but by the needs of recycling plastics sothat future actions should be made to remove that restriction and increase thepossibilities for recycling of plastics through appropriate collection andstorage of this urban solid waste.

REFERENCES

González, E., Modelación y optimización deun proceso tecnológico para la producción de cartón para ondular., Tesispresentada en opción al Grado Científico de Doctor en Ciencias Técnicas,especialidad Ingeniería Química, en la Universidad Central Marta Abreu de lasVillas, Cuba, 1982.

González, E., Pedraza, J., Ley, N.,Espínola F., Moya M., Aspectos técnico económicos en la proyección de instalacionesde la industria de la caña de azúcar, en el libro Aspectos técnico económicosde los estudios previos inversionistas para la producción de etanol de caña deazúcar., Editorial Cooperación Iberoamérica y Espacio Mediterráneo, Jaén,España, 2012.

Grancho, T., Posibilidad de producción ysustentación energética de la producción del plástico mediante el reciclaje desus desechos., Tesis presentada en opción al grado de Ingeniero Químico, en laUniversidad Central Marta Abreu de las Villas, Cuba, 2015.

IDF., Informe anual de Instituto deDesenvolvimento Florestal en Cabinda, 2013.

Ley, N., Contribución a los métodos deasimilar de tecnologías, aplicado a un caso de producción de biocombustibles.,Tesis presentada en opción al Grado Científico de Doctor en Ciencias Técnicas,especialidad Ingeniería Química, en la Universidad Central Marta Abreu de lasVillas, Cuba, 2006.

Muto, D., Hernández, G., do Rosario,J.F.B., Mamade, B. y Pedraza, J., Disponibilidad debiomasa como fuente de productos químicos y energía en Cabinda, Angola., CentroAzúcar, Vol. 41, No.3, 2014, pp. 14-27.

Muto Lubota, D.,González, E., Hernández, G., Miño, J., Modelo Conceptual y procedimientos paraasimilar tecnologías de producción de bioenergéticosde biomasa residual., Centro Azúcar, Vol. 43, No 3. 2016, pp. 29-38.

Oquendo, H., y González, E.,Consideraciones en la incertidumbre en el desarrollo de un procesoinversionista, Capítulo 10 del libro: Vías para el diseño de nuevasinstalaciones de la industria de procesos químicos fermentativos yfarmacéuticos, Editorial Científico-Técnica, La Habana, 2005, pp. 245-263.

Oquendo, H., González, E., Ley N., Nápoles,M., Cálculo de capacidades de producción iniciales óptimas considerandoelementos de incertidumbre., Centro Azúcar, Vol. 43, No. 2, 2016, pp. 24-34.

Peters, M.S., and Timmerhauss,K.D., Plant Design and Economics for Chemical Engineers., Singapore, Mc Graw –Hill, Chemical Engineering Series, 1981.

Rudd, D.F. and Watson, C.C., Strategy ofProcess Engineering., New York Mc Graw- Hill, 1968,pp. 309-329.

Sambovo, D.J., Posibilidad de producción ysustentación Energética de la producción del aluminio mediante el Reciclaje desus desechos. Tesis presentada en opción al grado de Ingeniero Químico, en laUniversidad Central Marta Abreu de las Villas, Cuba, 2015.

Recibido:Marzo 16, 2016;

Revisado:Abril 25, 2016;

Aceptado:Julio 28, 2016