Introduction

Microalgae culture acquire a great protagonism, being considered eco-friendly, since they efficiently recycle nutrients from liquid and gaseous media, incorporating them into their metabolism for biomass generation. 1

They rank among the most important biological resources that have the capacity to adapt to different environments, even in severe and extreme climatic conditions. Some are extremophile in terms of temperature (thermophilic), pH (acidophilic and alkalophilic). They represent the fastest growing plants on Earth; they can grow a hundred times faster than trees, so much that their weight can be doubled daily.2)

Microalgal biotechnology has gained importance in recent years due to the development of new environmental technologies, given that its growth requires low cost substrates and can be effective for obtaining high added value compounds. 3

In general, microalgae are grown in wastewater to obtain carbohydrates, lipids and proteins that are mainly focused on the production of fuel and animal feed. However, it is known that microalgae produce high value bioactive compounds, which may have different pharmaceutical and cosmetic applications. (4

They have the potential to reduce greenhouse gases (GHG), especially carbon dioxide emissions and the ability to assimilate nitrogen and phosphorus from wastewater.1,5,6 This efficient photosynthetic system is capable of converting solar radiation into chemical energy accumulated in the biomass with an efficiency comparable to higher yielding plants, such as sorghum, sugar cane, elephant grass and corn, in addition to the biomass It is usable and contains between 40 and 50% of proteins, not counting the content of vitamins, fats and other biofactors that act favorably on human health.7

The current production of microalgae biomass is low, only 9,000 tons of dry matter per year; the price of biomass is high, from 30 to 300 € kg-1, however, the size of these markets grows considerably. 8

The large-scale cultivation of microalgae seeks to obtain important quantities of a valuable product; therefore, the productivity of the system must be maximum. Understanding of the factors that determine optimal growth is critical: culture medium, gas exchange, pH, temperature and lighting regime. Temperature is a very important environmental factor due to its great influence on the development of microalgae. The effect of temperature on the biochemical composition mainly affects two different mechanisms: the rate of temperature dependence of chemical and biochemical reactions, and the temperature dependence for photosynthetic carbon fixation in several types of macromolecules, such as example proteins, carbohydrates and lipids. 9

The temperature is proportional to the production of microalgae, reaching optimal values for each species. Above this, respiration increases and photorespiration reduces overall productivity. The optimal values, in general, are between 28 °C and 35°C. 1

When it is a closed farming system, the temperature can be controlled easily by several mechanisms but in an open system, it is more difficult to control, since it depends on the meteorological conditions of the region. 10

The objective of this work is to evaluate the incidence of the suspension temperature in the biomass concentration of the mixed Chlorella Vulgaris culture in an open culture system existing in the pork hatchery "El Brujo" in Santiago de Cuba.

Materials and methods

Microorganism and general experimentation conditions

The cultivated species is the microalga Chlorella vulgaris, conserved in the collection of microalgae of the CIES at an average temperature of 25 oC.

The statistical data was taken from experiments carried out in a thin-film photobioreactor of 3500 m2 that is part of an integral waste treatment system located in El Brujo porcine feedlot areas in Santiago de Cuba, (figure 1). The other experimental conditions are referred by Alfaro and collaborators. 7

Meteorological Variables

The values of temperature, solar radiation, wind speed and relative humidity were taken from Actinometric station, coupled to a data acquisition system (Data logger MP-110) from the Solar Energy Research Center.

Results and Discussion

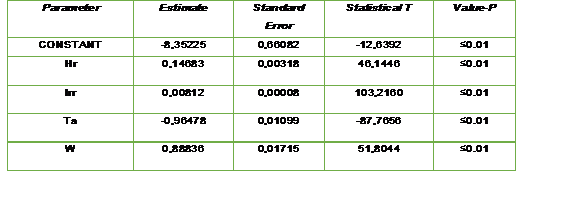

In an open culture system, the meteorological variables of the geographical location where it is located influence the temperature of the culture medium. To assess the incidence of the environmental parameters Relative humidity (Hr), Incidental solar irradiation (Irr), Ambient temperature (Ta) and Wind speed (W), in the culture temperature (Ts), multiple linear regression analysis is performed,(Table 1).

The multiple correlation coefficient, R2, obtained was 0.882, indicating that 88.2% of the variability of the response is caused by the effect of the factors.

The analysis of variance (table 2), determines that all the factors are statistically significant (p <0.05), that is, they influence the value of the response.

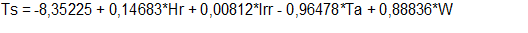

The adjusted model equation that describes the relationship between the temperature of the crop and the 4 independent variables is:

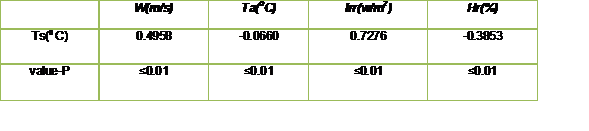

To assess the incidence of the environmental parameters Relative Humidity (Hr), Incidental Solar Irradiation (Irr), Ambient Temperature (Ta) and Wind Speed (W), in the Cultivation Temperature (Ts), a multivariate analysis is performed. Table 3 shows Pearson's product moment correlations between each pair of variables. The range of these correlation coefficients ranges from -1 to +1, and they measure the strength of the linear relationship between the variables. The P-value tests the statistical significance of the estimated correlations.

Values (p <0.05), indicate correlations significantly different from zero, with a confidence level of 95 %, observing that all the factors are statistically significant, that is, they influence the value of the response. Of these, solar irradiation is the one with the greatest influence, showing that 72,8% of the temperature variability depends on solar irradiation.

The statistical summary of the analyzed data was in table 4. The values of average temperature in the crop oscillate in the range of 29 ± 2 oC.

Biomass concentration at different average temperature values

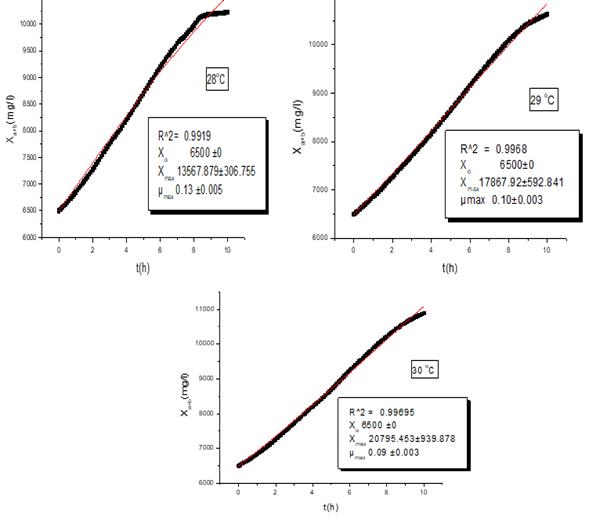

By means of a non-linear regression analysis, adjusting the data to the logistic or Verhuls growth model the maximum concentrations obtained are analyzed by comparing three values of average daily temperature (28oC, 29oC, 30oC), under the same growing conditions,(figure 1). The results show that the maximum concentration of biomass is 20,8 g.L-1 corresponding to the day of 30 o C of average temperature.

In a recent review of the optimal conditions of Chlorella cultivation Daliry and collaborators 11 report that the optimum temperature for Chlorella vulgaris is approximately 30°C, at which maximum productivity is reached. The range of temperature values reported by the authors as optimal coincides with the values obtained in this experiment, validating that the climatic conditions of the study region in Santiago de Cuba are favorable to achieve high productivities of mixed biomass of microalgae and bacteria.

Masojídek and collaborators 12 report studies carried out in a thin layer cascade photobioreactor in environmental conditions similar to ours (22 oC-36 oC), obtaining high productivities in a range of biomass concentration of 6,5-13,5 g.L-1 and estimate that sunlight was used efficiently. The low productivity, they suppose, was related to photoinhibition or photolimitation. The values reported in the present study coincide with these authors, reaching an optimum range of biomass concentration of (6,5-11) g.L-1 to obtain high biomass productivities.

Fig.1 Adjust to the microalgae and bacteria concentration data (Xa + b) to the kinetic model of Verhulst at three average temperatures in the crop (28oC, 29oC, 30oC)

Behavior of solar irradiation

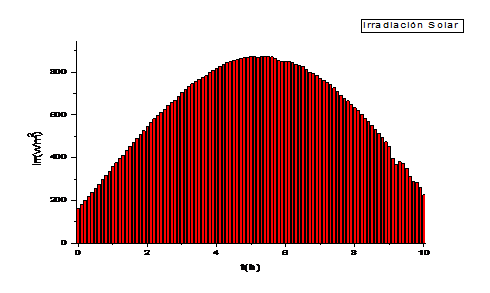

As the intensity of the specific radiant light depends on the direction of observation, it is advisable to use the integrated variables in all spatial directions and the visible spectrum in the modeled mathematical formulation. By integrating the solar irradiation data, the area under the curve can be visualized during the daytime. (Equation 2)

The attenuation of light in photobioreactors creates a heterogeneous radiation field within the crop, affecting local kinetics. Therefore, it is necessary to take into account the effects on the available growth in each point of the reactor. Figure 2 shows the behavior of solar irradiation at 10 o'clock on the day of maximum biomass concentration. The data obtained show the gradual increase until reaching the maximum values at noon, corresponding to 875,17 W/m2. The Accumulated solar intensity in the day was 6226,12 W/m2h.

Area Peak at Width Height

------------------------------------------------------------

6226,12 W/m2h 5,5 h 7,6 h 875,17/m2

Conclusions

The values of temperature in the crop are influenced by the meteorological variables of the locality, being the solar irradiation the one that has greater incidence reaching its peak values at noon.

The values of temperature in the culture medium are in the optimum range to obtain high concentrations of biomass.

The maximum biomass concentration value (20, 8 g. L-1) was obtained on the day analyzed at 30 OC average temperature.