My SciELO

Services on Demand

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Revista Cubana de Ciencias Forestales

On-line version ISSN 2310-3469

Rev cubana ciencias forestales vol.9 no.1 Pinar del Río Jan.-Apr. 2021 Epub Apr 03, 2021

Original article

Impact of the management control process oriented to excellence in the enterprise Agroforestry Macurijes de Cuba

1Universidad de Pinar del Río "Hermanos Saíz Montes de Oca". Pinar del Río, Cuba.

The purpose of this research is to analyze the impact of the excellence-oriented management control process on the development of capacities in agroforestry enterprises, taking the Macurijes Agroforestry Enterprise as a case study. For this purpose, the alignment between the processes and the criteria of forest management for excellence was determined; indicators were defined in order to evaluate the level of enterprise performance with respect to excellence and strategic lines for continuous improvement were proposed. As a main result, the contribution of the excellence-oriented management control process to the effective use of the enterprise's capabilities in terms of the satisfaction of its stakeholders was demonstrated. As a general conclusion, it is deduced that the adoption of this approach contributes to achieve important economic, social and ecological benefits derived from the effective use of all the enterprise's capabilities.

Key words: Management control; Excellence; Social responsibility; Agroforestry development.

INTRODUCTION

The management control process has evolved from a perspective that focuses its meaning on control through budgets that emphasizes the evaluation of projected measurements versus realities (ex-post), to a perspective in which it is intended to influence the achievement of future results, so that the probability of meeting the objectives set (ex-ante) is increased. This process is aimed at improving strategic decision making, and for this purpose, it takes into account the potentialities that organizations have, which is why it is essential to use relevant and pertinent information that involves all levels and functions of the organization; therefore, it is exercised at the strategic, tactical and operational levels (Nogueira et al., 2009; Jaquinet et al., 2015). In the case of agroforestry enterprises, it is a basic and indispensable process through which the content, objectives and information flow are established in a timely and relevant manner for decision making, in order to achieve the established objectives, taking into account the requirements of the forest management project and the needs of the interested parties (Pérez et al., 2020a).

Currently, information is understood as a strategic resource (Comas et al., 2014; Tundidor et al., 2019) and is of vital importance for the management of processes in agroforestry enterprises; that is why, information systems must be integrated, where all subsystems of the enterprise are covered and not one in itself. In this way, the processing and interpretation of the information allows to improve the ways of acting of the managers on the way to the enterprise excellence.

The excellence approach, within the management control process, facilitates the decision-making process because it increases the managers' capacity to act by providing them with tools that contribute to the control of the enterprise's tangible and intangible resources and capacities, according to their needs and the development of their capabilities, in balance with the limits established for the management of forest assets and the international standards that evaluate sustainable forest management.

The enterprises of the forestry sector develop different practices according to the areas and regions of the world and very diverse ecological, economic and social conditions, and also execute the works of conservation, protection and improvement of the natural environment (FAO, 2020); so it is possible to affirm that given the characteristics of agroforestry enterprises, it is evident the need to deepen this aspect as an object of control, which for the purposes of this research, strengthens the essence of the agroforestry enterprise in balance with the Sustainable Development Goals (SDGs), with the objectives of international and national organizations that govern the activity and with the enterprise interests.

For the adoption of this excellence-oriented management control process, the criteria for forest management for excellence (CGFE) of Pérez (2019) are used, which are based on the proposals of Herrero (2005), the Lepaterique process in 2005, the Montreal process in 2005 and 2009, the Tarapoto process in 2005, Cué (2015) and the proposal of the International Tropical Timber Organization of 2016; they conceive from an integrative perspective the evaluation of sustainability in its three dimensions through management control. These criteria are:

Existence of conditions for excellence-oriented forest management.

Establishment, maintenance and conservation of forest ecosystem integrity.

Sustainable forest production.

Strengthening and contribution to the local economy.

It is therefore proposed that excellence-oriented management control is the systemic and strategic process, aimed at monitoring and measuring results based on performance standards, the evaluation of associated risks and relevant and timely information, which allows senior management to adjust actions to gradually achieve a state of sustained success that contributes to the satisfaction of the needs and expectations of stakeholders (...), and in the case of agroforestry enterprises involves the use of the forest management project and the CGFEs as a primary source of information (Pérez et al., 2020b).

The purpose of this research was to analyze the impact of the excellence-oriented management control process on the development of agroforestry enterprises, taking the Macurijes Agroforestry Enterprise as a case study. For the fulfillment of this objective, the theoretical elements of the excellence-oriented management control process for this type of enterprise are described; the materials and methods used are detailed and, finally, the results of the research are presented.

MATERIALS AND METHODS

Characterization of the agroforestry organization under study

The Macurijes Agroforestry Enterprise is located at Km 9 ½ of the Guane to Mantua Highway in the westernmost region of the province of Pinar del Río, covering part of the territory of the municipalities of Guane and Mantua. Its geographical limits are: To the Northeast it borders with the municipality of Minas de Matahambres (Minas Agroforestry Enterprise) and with the coastline from Baja Cove to Garnacha Cove; to the East with the municipality of San Juan y Martínez (Pinar del Río Agroforestry Enterprise); to the South with the municipality of Sandino (Guanahacabibes Agroforestry Enterprise) and to the Southeast, with the coast of the Gulf of Mexico between the mouths of the Cuyaguateje and Puercos rivers.

The organizational structure includes seven basic enterprise units (UEBs), including two silvicultural UEBs with eight forest management units, three timber harvesting UEBs (two for lumber and one for wood preservation), one logistics UEB and one agricultural UEB.

The main productions are sawn timber, logs, round logs, tobacco drying chassis, charcoal for export, pallets, modules of storage boxes, and other products made from wood, valued both in local currency and in foreign currency. It is also engaged in the production and marketing of carpentry products, construction services, repair and maintenance of rustic works, reproduction and wholesale marketing of cattle, sheep, goats and pigs, as well as agricultural production of viands, vegetables, condiments and other non-timber forest products, such as resins, forest guanos and forest seeds. It also provides wood preservation services, forest management, forest development and management and construction of rustic works.

The enterprise's stated mission is to satisfy the needs and expectations of our customers in terms of variety and quality of timber and non-timber forest products, guaranteeing the sustainability of the forest, based on technological development, experience and specialization accumulated in the activity and social responsibility. The vision corresponds to: To be a leading enterprise at the national level in the sustainable production of forest products, with economically efficient, ecologically effective and socially efficient results".

Work methodology developed

For the development of the research a methodology containing four phases was applied.

Phase 1. Analysis of the alignment between CGFE and company processes

Source of information: the enterprise's management project, the analysis reports of the enterprise's subsystems, the CGFE and the evaluations of the working group that was formed for the development of the research.

An impact matrix was constructed, in whose rows the processes were placed and in whose columns the established criteria were placed. The impact of process (i) on the fulfillment of criterion (j) was then evaluated, with a value from 1 (low impact) to 10 (high impact). The average value for each process and criterion was calculated.

The level of concordance between the working group's assessments was evaluated using Kendall's coefficient and the relative weight was calculated to assess the level of importance of each of the processes in the criteria using the AHP method.

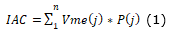

The criteria alignment index was calculated from the matrix of impact between the CGFE and the processes, as a premise for its calculation, the values in the matrix were analyzed, verifying that each criterion had reached a high impact (9 or 10) in some process. The criteria alignment index was calculated according to the expression "1" of Comas et al., (2015) (Equation 1).

Where:

IAC |

Index of criteria alignment |

Vme (j) |

Average value of the criterion |

P (j) |

Relative weight of the criterion |

N |

number of criteria |

To evaluate the index, the following levels were analyzed: High (6.50 - 10), Acceptable (5 - 6.49), Low (4.00 - 4.99) and Very low (4.00 - 4.99). (0 3,99).

Finally, the process alignment index was calculated with the criteria by expression "2" of Comas et al., (2015) (Equation. 2).

Where:

IAPr |

Process alignment index |

Vme (j) |

Average process value |

P (j) |

Relative weight of the process |

N |

number of processes |

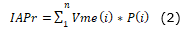

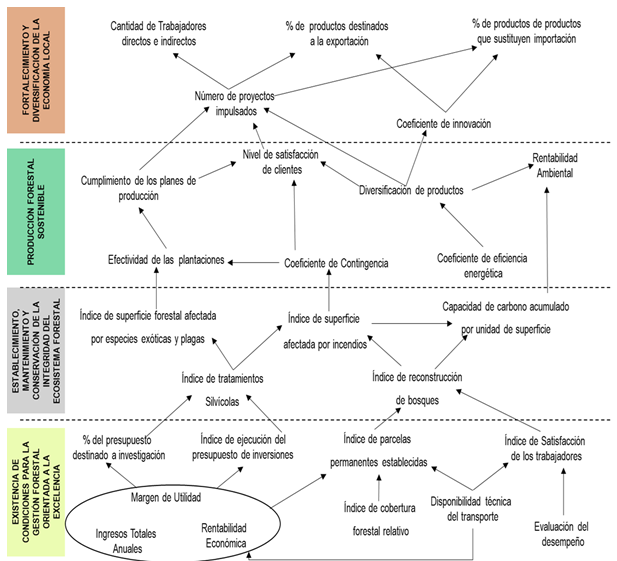

The alignment matrix between the FBGCs and the processes was constructed based on the results of the CAR and the PARR on a double-entry matrix that configures four quadrants (Figure 1).

Source: Own elaboration adapted from Comas et al. (2015).

Source: Own elaboration adapted from Comas et al. (2015).Fig. 1 - Alignment matrix between criteria and enterprise processes

The information shown in Table 1 was taken into account for the evaluation of the alignment (Table 1).

Table 1 - Possible courses of action according to the criteria and process alignment matrix

| QUADRANT | INTERPRETATION | ACTION |

| I | The CGFEs are aligned with the enterprise's processes. | Continue to develop the enterprise's strategy and define the indicators to measure the enterprise's performance based on the GFCFs. |

| II | Not all the GFCFs have their concretization in the processes. | Review the defined processes and identify those that do not contribute to the excellence management criteria. |

| III | Not all of the enterprise's processes contribute to the development of the CGFE. | Identify those distinctive qualities of each of the criteria and redefine them according to the context of the enterprise. |

| IV | There is no alignment between the criteria for excellence and the enterprise's processes. | Readapt forest management criteria for excellence to the context of the enterprise and assess the need for process reengineering. |

Phase 2. Definition of performance indicators

The indicators to evaluate the enterprise performance were defined in the processes associated with each criterion of forest management for excellence.

For this purpose, the following were taken into account:

The indicator's ability to represent processes and criteria.

Importance of the information resulting from the indicator to evaluate the enterprise's performance.

Cause-effect relationship with other indicators.

Importance given to the indicator (ratings given by the working group establishing the weighting of the indicators by criteria).

The following elements were taken into account for the mapping of cause-effect relationships:

Associate the indicators with the CGFEs.

Create a cause-effect relationship matrix.

Insert the indicators in each criterion in an orderly fashion, since the cause-effect relationship only exists between the indicators that are in the same criterion and the higher ones, thus simplifying the work.

Analyze the relationships between the indicators to verify that they really follow a cause-effect relationship.

Represent the relationships through a map that allows the visualization of the relationships.

Phase 3. Calculation of the enterprise's performance level

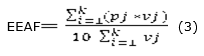

To assess the enterprise's performance, the results of the indicators were determined and the results are compared with the previous period to evaluate its compliance in a range from 1 to 10. Finally, the mathematical expression "3" was used to determine the enterprise's level of performance with respect to excellence (Equation 3).

Where:

Pj |

score given to the indicator |

Vj |

relative weight or weighting of the indicators |

K |

number of indicators |

The number ten represented the range of evaluation of the result of the performance standards of the indicators, from 1 to 10 where 1 (very bad) and 10 (very good), taking as a favorable limit the value (5). This mathematical formula made it possible to evaluate the level of performance based on the CGFEs and their location on the evaluation scale in Table 2 of the level achieved, which made it possible to guide actions for improvement (Table 2).

Table 2 - Scale of evaluation of the enterprise performance level

| Level | INTERVALS | PERFORMANCE | ORIENTATION | |

| I | 0,80 | 1, 00 | Excellent enterprise | Orientation towards excellence (total quality) |

| II | 0,60 | 0,80 | Enterprise with an emphasis on continuous improvement | Orientation towards quality management (efficiency) |

| III | 0,40 | 0,60 | An enterprise with a proactive approach to improvement. | Effectiveness (results) orientation |

| IV | 0,2 | 0,40 | Enterprise with a reactive approach to improvement | Efficiency orientation (use of resources) |

| V | 0 | 0,20 | Enterprise with no formal approach to improvement | No results or poor results or results of little significance |

Phase 4. Analysis of deviations and actions for continuous improvement

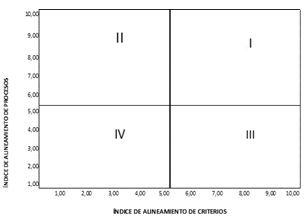

In this phase, after having obtained the level achieved by the enterprise with respect to its enterprise performance, the results were analyzed for each criterion of forest management for excellence and globally. In addition, taking as a reference the elements described in the NC ISO 9001: 2015 standard with respect to the needs and expectations of the interested parties, the impact of the enterprise's performance was checked taking into consideration the indicators within the CGFE that correspond to those of the standard.

Finally, improvement actions were proposed based on the indicators that were found to be below the established limits.

RESULTS AND DISCUSSION

Results of phase 1. Analysis of the alignment between the FBGCs and the enterprise's processes

Table 3 shows the results of the impact matrix between the enterprise's processes and the FBGCs as part of the alignment between them, according to the evaluations given by the working group, which obtained a level of agreement according to Kendall's coefficient of 0.86, which is significant. After determining the impacts, the averages of each process and each FBGC were calculated (Table 3).

Table 3 - Matrix of impact between the FBGCs and the processes

| PROCESSES | CRITERIA | ||||

| C1 | C2 | C3 | C4 | AVERAGE | |

| Quality management | 7 | 5 | 10 | 9 | 7,75 |

| Commercial management | 5 | 3 | 7 | 10 | 6,25 |

| Economic and financial management | 9 | 5 | 8 | 9 | 7,75 |

| Human talent management | 10 | 9 | 8 | 6 | 8,25 |

| Silviculture | 9 | 8 | 7 | 5 | 7,25 |

| Use | 6 | 6 | 8 | 9 | 7,25 |

| Livestock production | 3 | 4 | 2 | 9 | 4,5 |

| Maintenance | 9 | 10 | 7 | 5 | 7,75 |

| Transportation | 7 | 6 | 9 | 7 | 7,25 |

| Innovation management | 8 | 7 | 8 | 9 | 8 |

| Environmental management | 9 | 10 | 7 | 8 | 8,5 |

| AVERAGE | 7,454545 | 6,636364 | 7,363636 | 7,818182 | |

In order to calculate the strategic alignment index, it was analyzed that all the processes reached at least a high impact (9 or 10) in the matrix, to corroborate that all the CGFE are represented in the processes. The relative weight of each criterion and process was also determined through the AHP method, to assess their level of importance.

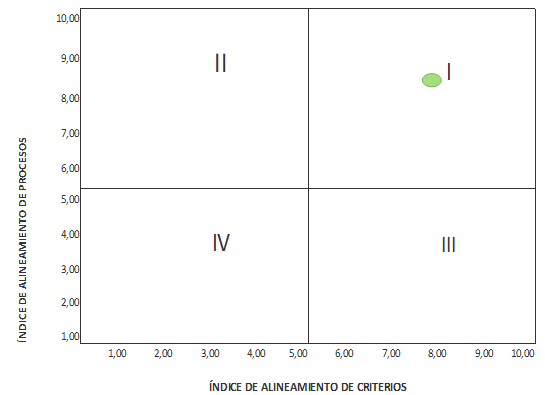

The analysis of the index of alignment between criteria in the enterprise, whose value was 8.074, showed that there is a high alignment between the CGFE; therefore, the defined criteria have their concretion in the processes (Table 4).

Table 4 - Calculation of the index of alignment of the CGFEs

| CRITERIA | AVERAGE | RELATIVE WEIGHT | |

| C1 | 8,272727 | 0,282 | 2,333 |

| C2 | 7,000000 | 0,195 | 1,365 |

| C3 | 8,454545 | 0,273 | 2,308 |

| C4 | 8,272727 | 0,250 | 2,068 |

| CRITERIA ALIGNMENT INDEX | 8,074 | ||

On the other hand, in order to construct the alignment matrix, the process alignment index was determined, whose value was 8.125 (Table 5).

Table 5 - Process Alignment Index Calculation

| PROCESSES | MEDIA | PESO RELATIVO | |

| Quality management | 8,5 | 0,07 | 0,595 |

| Commercial management | 7,25 | 0,09 | 0,6525 |

| Economic and financial management | 8,75 | 0,05 | 0,4375 |

| Human talent management | 9,00 | 0,15 | 1,35 |

| Forestry | 8,00 | 0,15 | 1,2 |

| Use | 8,5 | 0,16 | 1,36 |

| Livestock production | 5,00 | 0,07 | 0,35 |

| Maintenance | 8,25 | 0,05 | 0,4125 |

| Transportation | 7,25 | 0,05 | 0,3625 |

| Innovation management | 8,5 | 0,07 | 0,595 |

| Environmental management | 9,00 | 0,09 | 0,81 |

| PROCESS ALIGNMENT INDEX | 8,125 | ||

The alignment matrix between the processes and the CGFE of the Macurijes Agroforestry Enterprise (Figure 2) shows that it is in the first quadrant, so it is possible to continue with the development of the enterprise's strategy and define the indicators to measure the performance of the enterprise based on the CGFE.

Results of phase 2. Definition of performance indicators

As a core aspect of the management control process, indicators were defined (Table 6), (Table 7), (Table 8) and (Table 9), which constitute the control panel that allows monitoring the enterprise's performance, evaluating compliance with the CGFE, as well as the enterprise's orientation towards excellence.

Table 6 - Indicators for criterion I

| Criterion I: Existence of conditions for excellence in forest management | |

| 1 | Total annual income (TI) |

| 2 | Profitability (R) |

| 3 | Profit margin (MU) |

| 4 | % of research budget (I) |

| 5 | Investment Budget Execution Rate (IP) |

| 6 | Worker Satisfaction Index (IST) |

| 7 | Performance Evaluation (PE) |

| 8 | Technical status of transport (ETT) |

| 9 | Relative forest cover index (RFI) |

| 10 | Index of established permanent plots (Ppe) |

Source: Own elaboration based on proposals by Herrero (2005) and Cué (2015).

Table 7 - Indicators for criterion II

| Criterion II: Establishment, maintenance and conservation of forest ecosystem integrity | |

| 1 | Index of Silvicultural Treatments (ITS) |

| 2 | Forest rebuilding index (IRB) |

| 3 | Index of forest area affected by exotic species and pests (Ise) |

| 4 | Index of area affected by fire (Isi) |

| 5 | Accumulated carbon capacity per unit area (CCS) |

Source: Own elaboration based on proposals by Herrero (2005) and Cué (2015).

Table 8 - Indicators for criterion III

| Criterion III: Sustainable forest production | |

| 1 | Plantation Effectiveness (Ep) |

| 2 | Compliance with planned production volume (PV) |

| 3 | Diversification of production (DvP) |

| 4 | Coefficient of Energy Efficiency (CEe) |

| 5 | Environmental profitability (AR) |

| 6 | Contingency Coefficient (CCo) |

| 7 | Customer Satisfaction Level (CSL) |

Source: Own elaboration based on proposals by Herrero (2005) and Cué (2015).

Table 9 Indicators for criterion IV

| Criterion IV: Strengthening and contribution to local economy | |

| 1 | % of products for export (PEx) |

| 2 | % of products substituting imports (PM) |

| 3 | Innovation coefficient (CIN) |

| 4 | Number of projects promoted (NPI) |

| 5 | Number of direct and indirect workers (TDI) |

Source: Own elaboration based on proposals by Herrero (2005) and Cué (2015).

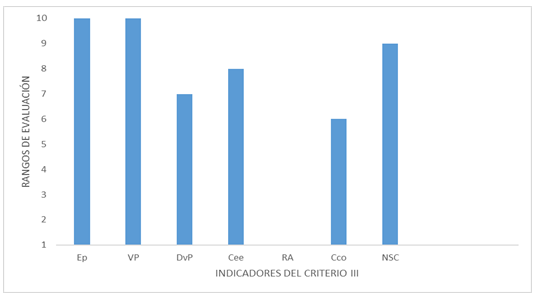

A cause-effect relationship map was also drawn up, which translates into an action tool for enterprise decision making.

The indicators were associated by criteria and a cause-effect relationship matrix was created (Figure 3).

Results of phase 3. Calculation of the enterprise's performance level

The methods for calculating the indicators of the forest management criteria for excellence were applied, taking into consideration the sources of information declared for each one. With the results of the behavior of the indicators, the level of performance of the enterprise was determined, which showed a result of (0.72) that places it in level II, which means an orientation towards quality management (effectiveness) according to the information in Table 2.

This result shows a paradigm shift in enterprise management, since its focus of action moves from inputs to the generation of results and impacts that will be perceived by stakeholders. For this, it is important to permanently seek excellence in its management, through continuous self-evaluation and projection.

Results of phase 4. Analysis of deviations and actions for continuous improvement

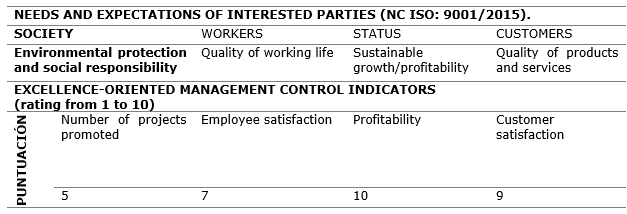

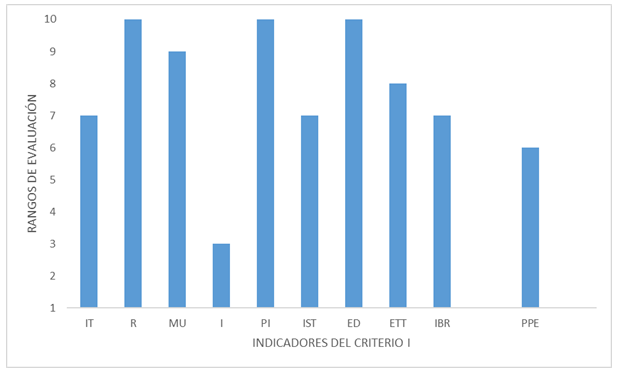

The results of the indicators for each criterion were evaluated on a scale of 1 to 10 (5 being the favorable limit value) according to their level of performance as shown in Figures 4, 5, 6 and 7.

Among the indicators related to criterion I (Figure 5), those with the highest favorable impact were: profitability, investment budget execution rate and performance evaluation; while the one that has an unfavorable impact is: % of the budget allocated to research. This result is in correspondence with the national panorama regarding research funding, which, according to Torres et al., (2018), is hindered by the absence of financial and material resources that prevent following up on research, resistance to change on the part of the enterprises to introduce the results and the absence of rules and regulations that tribute to their generalization and the lack of knowledge of the personnel involved and managers.

Fig. 4 - Analysis of the indicators of Criterion I "Existence of conditions for excellence-oriented forest management"

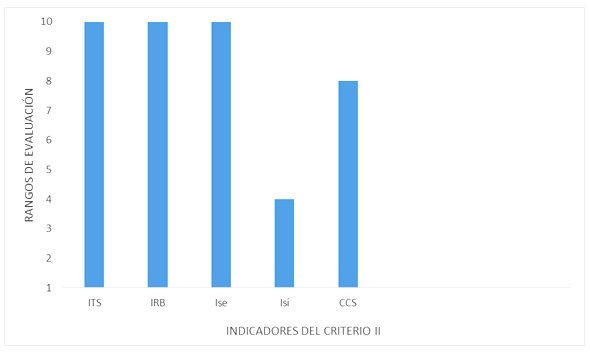

In the case of criterion II, the indicators that obtained a favorable evaluation were: the index of forest cover affected by exotic species and pests, index of forest reconstruction, index of silvicultural treatments. In the case of area affected by fire and carbon sequestration, they were evaluated unfavorably (Figura 5).

In the first case, it is vitally important to analyze the causes of the occurrence of fires in the areas comprising the enterprise, given that these events are considered the third cause of the loss and degradation of large areas of forest land (Gutiérrez et al., 2015) cited in Pérez et al., (2017).

Regarding the carbon sequestration indicator, it was evaluated unfavorably, as there was no evidence of records of carbon sequestration analysis in the enterprise, which limits the decision-making process with respect to the forest, in order to ensure the survival of the forest ecosystem and the improvement of its environmental, socio-cultural and economic functions. Carbon sequestration estimates make it possible to establish strategies aimed at mitigating climate change, which is why it is vitally important for the enterprise to obtain and use this information for the comprehensive evaluation of the enterprise's performance.

Fig. 5 - Analysis of indicators for Criterion II "Establishment, maintenance and conservation of forest ecosystem integrity"

In criterion III, production diversification is one of the indicators that behaved unfavorably, as a consequence of a low level of innovation and incentives for research that do not allow the results generated from science to reach the implementation stage, which is in correspondence with the information resulting from criterion I. Environmental profitability is another indicator that reflects a behavior below the favorable range, which is relevant for the reuse of forestry residues, since the international and national market promotes techniques and actions to eliminate polluting sources and obtain the maximum profitability of the enterprise's resources (Figure 6).

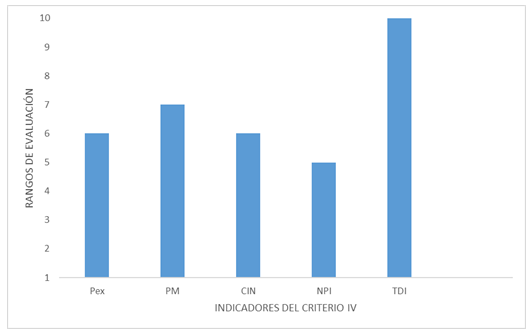

The behavior of the indicators associated with criterion IV showed that the enterprise can further strengthen the generation of products for export and import substitution, which guarantee the contribution in monetary terms and/or in products to the locality, according to the results shown in Figure 7. Given that import substitution of this type of products, with higher added value in which the enterprise has the potential to increase its production capacity in a sustainable manner, it is essential to reduce the sector's trade deficit (Torres et al., 2018) (Figura 7).

In the case of the indicator that expresses the number of projects promoted by the enterprise, its performance was below expectations, which is an element that affects the integral development of the enterprise and the territory. Since both public and enterprise planning mechanisms have been showing a transition from centralization schemes to a greater recognition of the importance of the territory as a factor of development, it is important to note that the number of projects promoted by the enterprise has been increasing (Capote et al., 2018).

Fig. 7 - Analysis of the indicators for Criterion IV "Strengthening and contribution to the local economy"

In general, it was determined that the KFCs performed favorably in the enterprise, even though some deviations were found. The CGFEs on which senior management should focus actions for improvement towards excellence, taking into consideration the results of the indicators, were: "Sustainable production" and "Establishment, maintenance and conservation of the forest ecosystem". In addition, the indicators for the evaluation of the CGFEs were aligned with the elements that reflect the impact of the enterprise's performance on the stakeholders according to the ISO: 9001/2015 NCs, in order to assess its impact on them (Table 10).

The results in Table 10 show that, of the stakeholders involved, emphasis should be placed on "Society", which, according to the standard, addresses the need for "Protection of the natural environment and social responsibility", in line with the evaluation of the indicator "Number of projects promoted", which has the lowest score, even though it is within the acceptable limit (5).

Finally, four strategic lines were determined for the continuous improvement of the enterprise's performance, in response to the deviations found in the evaluation of the CGFE. The lines that were formulated respond to:

Identify the enterprise's potential with respect to the diversification of production, which will contribute to the increase of exports and import substitution.

Promote the presentation of projects for the development of the locality as part of the enterprise's social responsibility.

Contribute to the maintenance and conservation of the natural environment through the use of alternative energies for the enterprise's processes, the monitoring of contingency funds and the reuse of natural waste from the production process, both for the generation of new products and for sale, which will increase the enterprise's profitability.

To train the enterprise's human resources to promote enterprise development.

CONCLUSIONS

The implementation of the excellence-oriented management control process in the Macurijes Agroforestry Enterprise contributed to the development of capabilities for the improvement of decision-making, which was reflected in the evaluation of the enterprise's performance level through the CGFE. Consequently, in order to gradually reach a state of sustained success that contributes to satisfying the needs and expectations of stakeholders, it will be necessary to promote the enterprise's integral development, taking into consideration strategic lines focused on diversifying production, designing and implementing projects, conserving the natural environment, and increasing the efficiency and effectiveness of human resources.

The excellence-oriented management control process provides a broader view of the enterprise's current situation with respect to enterprise excellence, analyzes its possible projection and, based on this, provides information to guide its performance towards continuous improvement.

Acknowledgments

To the Agroforestry Enterprise Group of the Ministry of Agriculture, who facilitated the development of the research. To the directors and workers of the Macurijes Agroforestry Enterprise for their involvement and active participation in the research.

REFERENCIAS BIBLIOGRÁFICAS

CAPOTE PÉREZ, R., TORRES PÁEZ, C.C. y CASTILLO SÁNCHEZ, L. del, 2018. Retos de la Administración Pública para la gestión del proceso de financiamiento del desarrollo local. Cooperativismo y Desarrollo [en línea], vol. 6, no. 2, pp. 179-197. ISSN 2310-340X. Disponible en: http://coodes.upr.edu.cu/index.php/coodes/article/view/206. [ Links ]

COMAS RODRÍGUEZ, R., NOGUEIRA RIVERA, D., BARTUTIS, F. y RODRÍGUEZ, M., 2015. Integración de herramientas para el control de gestión. Análisis de un caso de estudio. Enfoque UTE [en línea], vol. 6, no. 3, pp. 1-19. DOI 10.29019/enfoqueute.v6n3.65. Disponible en: https://www.researchgate.net/publication/320993065_Integracion_de_herramientas_para_el_control_de_gestion_Analisis_de_un_caso_de_estudio. [ Links ]

COMAS RODRÍGUEZ, R., NOGUEIRA RIVERA, D. y MEDINA LEÓN, A., 2014. El control de gestión y los sistemas de información: propuesta de herramientas de apoyo. Ingeniería Industrial [en línea], vol. 35, no. 2, pp. 214-228. ISSN 1815-5936. Disponible en: https://rii.cujae.edu.cu/index.php/revistaind/article/view/516 [ Links ]

CUÉ GARCÍA, J.L., 2015. Criterios e indicadores del manejo forestal sostenible: una alternativa para su monitoreo. Revista Cubana de Ciencias Forestales [en línea], vol. 3, no. 2, pp. 183-193. ISSN 2310-3469. Disponible en: http://cfores.upr.edu.cu/index.php/cfores/article/view/128. [ Links ]

HERRERO ECHEVARRIA, J.A., 2005. Criterios e indicadores de manejo forestal sostenible: una vision de futuro. Agronfor [en línea]. La Habana: Ministerio de la Agricultura, Disponible en: https://agris.fao.org/agrissearch/search.do%3FrecordID%3DXF2015034562+&cd=1&hl=es-419&ct=clnk&gl=cu. [ Links ]

JAQUINET ESPINOSA, R., FRÍAS JIMÉNEZ, R.A., FRÍAS PEDROSO, L., NOGUEIRA RIVERA, D. y GARCÍA GUTIÉRREZ, B.N., 2015. Control de gestión: Facultad de Ciencias Económicas e Informática, Universidad de Matanzas. Ingeniería Industrial [en línea], vol. 36, no. 1, pp. 70-81. ISSN 1815-5936. Disponible en: http://scielo.sld.cu/scielo.php?script=sci_abstract&pid=S1815-59362015000100008&lng=es&nrm=iso&tlng=es. [ Links ]

NOGUEIRA RIVERA, D., MEDINA LEÓN, A., HERNÁNDEZ PÉREZ, G., NOGUEIRA RIVERA, C.N. y HERNÁNDEZ NARIÑO, A., 2009. Control de gestión y cuadro de mando integral: énfasis en la perspectiva financiera-aplicación en una empresa de servicios de informática. Revista de Administração - RAUSP [en línea], vol. 44, no. 3, pp. 222-235. ISSN: 0080-2107, 1984-6142. Disponible en: https://www.redalyc.org/articulo.oa?id=223417462004 [ Links ]

ORGANIZACIÓN DE NACIONES UNIDAS PARA LA AGRICULTURA Y LA ALIMENTACIÓN (FAO), 2020. Monitoreo del progreso hacia la GFS [en línea]. 2020. S.l.: FAO. en: http://www.fao.org/forestry/sfm/85101/es/. [ Links ]

ORGANIZACIÓN INTERNACIONAL DE NORMALIZACIÓN, 2015. Sistemas de Gestión de la Calidad-Requisitos [en línea]. 2015. S.l.: s.n. Disponible en: http://www.cucsur.udg.mx/sites/default/files/iso_9001_2015_esp_rev.pdf. [ Links ]

PÉREZ PEREDA, E., RAMÍREZ FERNÁNDEZ, L., MASSÓ MATOS, J., DURAN MANUAL, F., 2017. Acciones para disminuir el peligro de incendios forestales en los municipios San Antonio del Sur e Imías, Guantánamo. Revista Cubana de Ciencias Forestales , [en línea]. v. 5, n. 2, p. 226-246, aug. 2017. ISSN 2310-3469. Disponible en: http://cfores.upr.edu.cu/index.php/cfores/article/view/213. [ Links ]

PÉREZ MARTÍNEZ, J., 2019. Modelo de control de gestión orientado a la excelencia para empresas agroforestales [en línea]. Tesis de Doctorado en Ciencias Económicas. S.l.: Universidad de Pinar del Río «Hermanos Saíz Montes de Oca». Disponible en: https://rc.upr.edu.cu/jspui/handle/DICT/3558 [ Links ]

PÉREZ MARTÍNEZ, J., FERNÁNDEZ HERNÁNDEZ, M.E. y NUEZ HERNÁNDEZ, D. de la, 2020a. Indicadores para el control de gestión orientado a la excelencia, por un desarrollo integral forestal. Cooperativismo y Desarrollo [en línea], vol. 8, no. 1, pp. 57-67. ISSN 2310-340X. Disponible en: http://coodes.upr.edu.cu/index.php/coodes/article/view/254. [ Links ]

PÉREZ MARTÍNEZ, J., FERNÁNDEZ HERNÁNDEZ, M.E. y NUEZ HERNÁNDEZ, D. de la, 2020b. Control de gestión orientado a la excelencia; una aproximación teórica desde las ciencias sociales. Revista Caribeña de Ciencias Sociales (enero 2020). Disponible en: https://www.eumed.net/rev/caribe/2020/01/gestion-orientado-excelencia.html//hdl.handle.net/20.500.11763/caribe2001gestion-orientado-excelencia [ Links ]

TORRES CALA, Y., GONZÁLEZ PÉREZ, M.M., RAMÍREZ CRUZ, Z. y MUÑOZ GONZÁLEZ, R., 2018. El proceso de innovación en el sector forestal cubano y su contribución a la economía nacional. Revista Cubana de Ciencias Forestales [en línea], vol. 6, no. 2, pp. 146-161. ISSN 2310-3469. Disponible en: http://cfores.upr.edu.cu/index.php/cfores/article/view/329. [ Links ]

TUNDIDOR MONTES DE OCA, L., NOGUEIRA RIVERA, D. y MEDINA LEÓN, A., 2018. Organización de los sistemas informativos para potenciar el control de gestión empresarial. Cofin Habana, vol. 12, no. 1, pp. 88-110. ISSN 2073-6061. Disponible en: http://scielo.sld.cu/scielo.php?script=sci_abstract&pid=S2073-60612018000100007&lng=es&nrm=iso&tlng=es [ Links ]

Received: September 21, 2020; Accepted: February 26, 2021

text in

text in