INTRODUCTION

Software in recent decades has become an effective tool in the designing and management of irrigation systems, with the aim of maximizing agricultural production with efficient use of natural resources, as a low-cost alternative, quick and easy to use (Kisekka et al. 2016, Ferreira and Assunção, 2015, Pinheiro and Alves, 2017).

In the Ministry of Agriculture of the Republic of Cuba, pressure irrigation systems are the ones with the highest consumption of electric power, between 18% and 20% (López et al. 2017a). Hence, it arises the need of analyzing the design, operation and evaluation of these systems. In Cuba, in the nineties, the software "PIVOT" was developed for the design of central pivot irrigation systems by hydraulic and electric drive, but this does not include the hydrogeological parameter, the hydraulic in all its extension and the economic ones ( López et al. 2017b).

There have been several authors who have developed methodologies and software for the design and evaluation of central pivot irrigation systems such as Allen (1991); Valin et al. (2012); Moreno et al. (2012); Irmak, (2015); Almedia et al. (2017); Camejo et al. (2017); but they have as limitations the analysis of the topography of the terrain, the hydraulics of well, the curves of the centrifugal pumps, the types of emitters in the lateral and economic aspects. For this reason, the importance of developing software based on optimal methodologies that integrate all the variables for the design of central pivot irrigation systems is inevitable, and thus contribute to increase the efficiency and productivity of irrigation.

In this sense, the objective of this work is to develop a software for the hydraulic design of central pivot irrigation systems under specific operating conditions that include the hydrogeological, hydraulic, soil, agronomic and economic variables to obtain the design flow.

METHODS

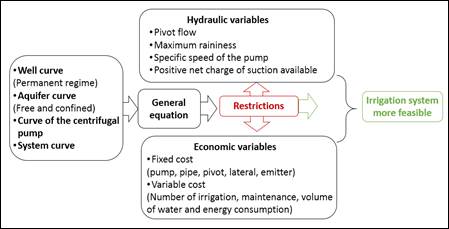

The CurvePivot 2.0 software was implemented based on the mathematical model proposed by López et al. (2017b), attributing new working conditions, both for free and confined aquifers, considering a linear flow in a permanent regime in the well; as well as agronomic, operational and economic variables that determine the design of the central pivot as shown in flow diagram 1.

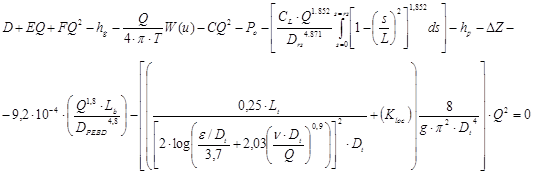

The general equation of the mathematical model that integrates the combination of the aquifer curve, the well, the centrifugal pump and the curve of the irrigation system is explained by the following expression:

Where:

Q |

- pump flow rate (m3 s-1) |

D, E, F |

- adjustment coefficients of the curve |

hg |

- suction height of the static water level in the well (m) |

T |

- transmissivity (m2 s-1) |

W(u) |

- "u" function of the well |

CQ2 |

- descent into the well (m) |

Po |

- pressure of the last emitter on the lateral (m) |

CL |

- roughness coefficient of the pipe |

Drs |

- internal diameter of the lateral pipe (m) |

s |

- integration from the start of the lateral to the distance rs (m) |

L |

- length of the irrigation lateral (m) |

hp |

- height of the pivot (m) |

ΔZ |

- topographic difference between the point of the pivot and the extremity of the lateral (m) |

Lb |

- length of the emitter support pipe (m) |

DPEBD |

- internal diameter of the emitter support pipe (m) |

Lt |

- length of the suction and discharge pipe respectively (m) |

Dt |

- internal diameter of the suction and discharge pipe, respectively (m), the diameters are considered equal |

ε |

- absolute roughness of the pipe (m) |

v |

- kinematic viscosity (m2 s-1) |

Kloc |

- local loss coefficients (dimensionless) |

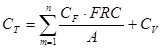

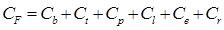

The economic diameter for the design flow was determined in the expression (1), from the analysis of the fixed and operation costs of the system, using the commercial diameters existing in the market for central pivot irrigation systems, the expression is shown by the following equation:

Where:

C T |

- total cost ($ ha-1 year-1) |

C F |

- fixed cost ($ year-1) |

C v |

- variable cost ($ ha-1 year-1) |

A |

- irrigation area (ha) |

FRC |

- investment recovery factor (%) |

r |

- real interest rate |

t |

- useful life of the investment (years) |

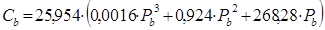

The fixed costs in formula (2), are the sum of the costs of the pump, the impulsion pipe, the pivot, the lateral; as well as the type of emitter and pressure regulator. While the cost of the pump is a function of its power and the cost of the pivot depending on the diameter, according to studies by Montero et al. (2012), that are expressed by the equation:

Where:

C b |

- cost of the pump ($) |

C t |

- cost of the impulse pipe ($) |

C p |

- cost of the pivot ($) |

C l |

- cost of the lateral ($), depending on the number of the towers and the diameter |

C e |

- cost of the emitter type ($) |

C r |

- cost of the pressure regulator ($) |

P b |

- power of the pump (kW) |

D |

- diameter of the pivot (mm) |

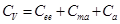

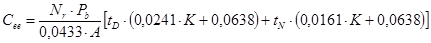

The variable costs of formula (2) depend on the operation of the irrigation system, which is defined as the sum of the cost of energy, the cost of maintenance and the cost of water that are expressed by the equation:

Where:

C ee |

- cost of electricity consumed ($ ha-1 year-1) |

C ma |

- maintenance cost ($ ha-1 year-1) |

C a |

- cost of water ($ ha-1 year-1) |

C W |

- cost of the volume of water extracted (0,01 $ m-3according to Resolution No. 421/2012 |

t D |

- daytime work time per month (h) |

t N |

- nightly work time per month (h); the irrigation area (ha) |

Tm |

- annual maintenance rate (%) |

PS |

- purchase and installation price of the irrigation equipment ($) |

K |

- adjustment coefficient for variation of the price of the fuel according to Resolution No. 28 / 2011 |

N r |

- number of irrigations (dimensionless) |

ƞ b |

- efficiency of the pump (decimal) |

H b |

- manometric height of the pump (m) |

ϒ |

- specific weight of the water (9,806 kN m-³). |

RESULT AND DISCUSSION

The CurvePivot 2.0 software was developed. It allows the hydraulic design of central pivot irrigation systems for specific operating conditions, including hydrogeological, hydraulic, soil, agronomic and economic variables.

The program was designed with a simple interface that allows the user greater concentration on the content of the work. It was used as WPF technology contained in the Framework. Net in its version 4.0 and as a programming language C # was used in its version 5.0 and as Interface Development Enviroment Visual Estudio 2015, compatible with the Windows XP version onwards.

The user accesses in a logical and orderly manner indicated below from the information stored and entered as insert, select and import data from Microsoft Excel, remove and update data, diameters and materials of the pipes, types of towers, emitters and soils, sample of results, obtaining equations and curves of the system; sample of the point of operation of the system and runoff and print tables or figures. The software consists of three vital interfaces:

The first part, to the group of tabs which group the input fields (well, pump, pipe and central pivot) together with a result table, always visible to the user.

The second part is accessed through the run-off button on the navigation bar by entering the input fields for the runoff calculation and the result table.

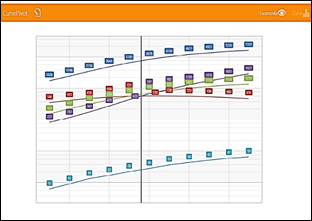

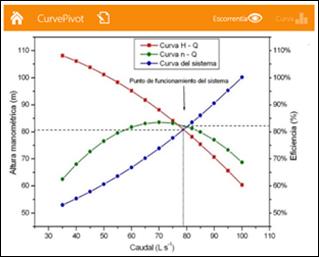

The third part, the user accesses by the curved button of the navigation bar to access the curves generated by the pump and irrigation system.

The following figures show an example of the features and operation of the CurvePivot 2.0 Software for the design of the center pivot. Figure 2 shows the main screen of the computer system; while, in Figure 3, the screen to enter the exploitation data of the well and the aquifer is observed. Some of those data are transmissivity, storage coefficient and the coefficients of losses of the well according to the constructive characteristics, as well as the groundwater levels of the aquifer.

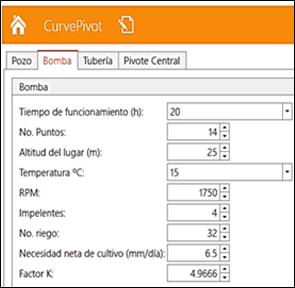

Figure 4 shows the data input screen of the centrifugal pump and agronomic variables. The pump curve, the operating time of the pump, number of impellers, irrigation number, maximum crop evapotranspiration, the coefficient of adjustment for variation of the price of fuel such as the K factor, among others are selected. Figure 5 shows the data entry screen of the discharge pipe.

Figure 6 shows the data entry screen of the central pivot, the characteristics of the lateral pipe and emitter are selected, as well as the efficiency of the system. Figure 7 shows the data screen of the type of soil and crop to be irrigated.

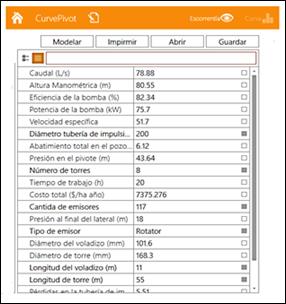

Figure 8 shows the results screen of the irrigation system, such as the depletion of the well, the operating parameters of the centrifugal pump, diameters and lengths of the pipes, working pressure, tower number, speed of the last tower and total cost of the irrigation system. This screen allows the most appropriate technical and economic selection to increase the efficiency of realization of irrigation projects with central pivots in real operating conditions. In this way, a reduction of expenses of material, human and energy resources and the time to perform the calculations and analysis is achieved, guaranteeing a greater technical and economic control of the design of the irrigation system with the minimum resources.

Figure 9 shows the curves of the operating point of the system (Hb v Q; η v Q and system curve), which facilitates the interpretation and visualization of the technical results for the increase in the useful life of the pump, from the stabilization of the operating point allowing lower maintenance cost due to the mechanical seals, bearings and less probability of misalignment of the shaft.

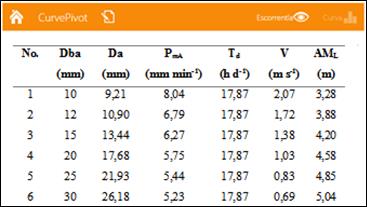

Figure 10 shows the results of the runoff at the end of the lateral. These values enable the appropriate selection of the emitter type to avoid runoff at the end of the lateral, depending on the type of emitter, which favours the rational use of water and energy in the irrigation system.

CONCLUSIONS

The CurvePivot 2.0 software was developed, which constitutes a technological innovation of utmost importance that allows realizing the optimal hydraulic design of central pivot irrigation systems for specific operating conditions.

The implementation of the CurvePivot 2.0 software allows the efficient elaboration of central pivot irrigation projects in less time, facilitates the interpretation and visualization of the economic technical results that have an impact on the increase of irrigation productivity; as well as the reduction of environmental impacts.

texto en

texto en