Mi SciELO

Servicios Personalizados

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista de Salud Animal

versión impresa ISSN 0253-570X

Rev Salud Anim. vol.36 no.2 La Habana Mayo.-ago. 2014

SHORT COMMUNICATION

Influence of culture medium components on Mycoplasma gallisepticum growth

Influencia de los componentes del medio de cultivo en el crecimiento de Mycoplasma gallisepticum

Tania Pérez BuenoI*, Lilian Sánchez MirandaI, Ileana Rosado Ruiz-ApodacaII, Tito Díaz BravoIII, Mercedes Rodríguez EdreiraIV, Siomara Martínez MarreroI

INational Center for Animal and Plant Health (CENSA). Carretera de Jamaica y Autopista Nacional. Apartado 10, San José de Las Lajas, Mayabeque. Cuba.

IINational Center of Medical Genetics. Ave. 31 Esq. 146 No. 3102, Reparto Cubanacán, La Habana. Cuba.

IIILatin American School of Medicine. Carretera Panamericana Km 3½, Santa Fe, La Habana. Cuba.

IVHigher Polytechnic Institute «José A. Echeverría». Calle 114 e/ 119 y 129, Marianao, La Habana. Cuba.

ABSTRACT

The composition of a culture medium produced in Cuba to grow Mycoplasma gallisepticum was evaluated using a response surface methodology. Initially, the influence of Mycoplasma base, horse serum and yeast extract on biomass production was assessed in a 23 factorial experimental design. Then, a central composite design was applied. Mycoplasma base and horse serum factors were selected for this study. In 7 L and 35 L bioreactors, the variations carried out in the culture medium composition were estimated. The experimental results were fitted to a second order polynomial model equation. Finally, the optimal growth conditions established were at concentrations of 1,88% Mycoplasma base and 18,16% horse serum (v/v) with 0,6% of yeast extract. For the conditions tested, at a bioreactors scale, a high cellular yield of M. gallisepticum (higher than 0,5 ODu/mL) was obtained.

Key words: culture medium optimization, Mycoplasma gallisepticum, statistical experimental design.

RESUMEN

Se evaluó la composición de un medio de cultivo de producción nacional para el crecimiento de Mycoplasma gallisepticum, utilizando la metodología de superficie de respuesta. Inicialmente se estudió la influencia de los componentes Micoplasma base, suero equino y extracto de levadura para la producción de biomasa, mediante un diseño factorial 23 y a continuación se aplicó un diseño compuesto central. Los valores de los componentes del medio de cultivo, definidos a escala de laboratorio, fueron experimentados en fermentadores de 7 L y 35 L. Los resultados del diseño compuesto central fueron ajustados en un polinomio de segundo orden, alcanzando un crecimiento óptimo a las concentraciones de 1,88% de Micoplasma base y 18,16% de suero equino (v/v) fijando el extracto de levadura en 0,6%. Se alcanzaron rendimientos celulares de M. gallisepticum superiores a 0,5 ODu/mL en fermentadores de 7 L y 35 L.

Palabras clave: optimización de medio de cultivo, Mycoplasma gallisepticum, diseño estadístico experimental.

Mycoplasma gallisepticum (MG) is a significant respiratory and reproductive pathogen of domestic poultry (1, 2). Economic losses due to downgrading reduced feed, egg-production efficiency and medication costs have become MG infection in one of the costliest diseases faced by the poultry industry (3, 4). The current measures to combat MG infection have included flock testing and eradication programs, as well as the use of antibiotics in both prophylactic and therapeutic application and vaccination (5, 6).

The Mollicutes (mycoplasmas) are among the most nutritionally fastidious groups of microorganisms and have been notoriously difficult to cultivate (7). The culture medium for the cultivation of mycoplasma species requires a complex formulation of ingredients currently regarded as essential nutrients. The most frequently used basic formulations containing a broth base, composed by beef heart infusion, peptone and other ingredients, yeast extract, glucose and sterol (animal serum), were added to this broth base.

Varela et al. (8) designed a broth base for MG growth which expressed good cell yields compared with commercial media for mycoplasmas like DIFCO and OXOID (9). This culture medium was used in biomass production of MG for vaccination (10).

In the field of fermentation technology, study of the culture medium is a very important aspect for improving product yield and reducing process variability, as well as for reducing the development time and overall costs (11). Due to the complexity of the culture medium and the difficulties to cultivate MG, the response surface methodology (RSM) is an approach that can be used to study the effect of several variables and to seek the better conditions for a multivariable system (12,13,14).

Therefore, the aim of this work was to study the composition of a culture medium produced in Cuba to grow MG, by using a central composite design (CCD).

The strain M. gallisepticum S6 (ATCC 15302), deposited in CENSA´s culture collection (15), was grown in Mycoplasma broth medium (BioCen, Cuba), supplemented with horse serum and yeast extract (supplemented MBM) (8). The horse serum was supplied by LABIOFAM (Cuba), and the yeast extract was obtained from BioCen (Cuba). The horse serum was prepared by filtrating and heating for 30 minutes.

For the laboratory studies, 7,5 mL of cell suspension were inoculated into the 75 mL supplemented MBM in a 150 mL Erlenmeyer flask. This culture was incubated at 37 °C and 90 rpm for 14 h (9).

For the fermentation studies, the inoculum was introduced into 7 L and 35 L bioreactors (Chemap-Braun, Germany), containing 5 L and 30 L respectively of the supplemented MBM. The fermentation parameters controlled were: pH 7,8, temperature 37 °C, 120 rpm and 0 vvm, operated in a batch-wise mode up to 20 h of culture time in both bioreactors (9, 16).

The biomass concentration was measured by sampling the culture and reading the optical density (OD) at a wavelength of 540 nm.

The number of colonies formed (CFU) was determined by plating suitable dilutions of cultures on agar medium and the colonies counted after incubation for 48 hours at 37°C. The procedure was performed as described in a previous paper (16). Samples were taken in duplicate every four hours.

The influence of the culture medium components was studied in shake flask experiments, specifically, the concentration of Mycoplasma base (Mb), horse serum (Hs) and yeast extract (Ye).

Factorial design: A 23 factorial experimental design and a midpoint were applied to the screening of the variables indicating where to improve yields (17). The variables (factors) were the concentrations of Mycoplasma base (X1), horse serum (X2), and yeast extract (X3) in the supplemented MBM. The cell concentration measured as OD was the response variable (Y).

The variables were tested in three coded levels: low (-1), medium (0) and high (+1). The coded values corresponded for the variables as follows: X1: -1 (20 g/L), 0 (25 g/L), +1 (30 g/L); X2: -1 (160 mL/L), 0 (200 mL/L), +1 (240 mL/L); X3: -1 (6 g/L), 0 (10 g/L), + 1 (14 g/L). The midpoint (coded value 0) corresponded to the quantities commonly used (Control).

Central Composite Design: Once the direction improving yields was known, a star design (with the coded value a = ± 1,682) (18) was performed to determine a better statistical model which described the relationship between the variables Mb and Hs. The variable yeast extract was kept fixed at the value indicated in the factorial design. The levels studied in the CCD are shown in Table. The X value for a (Xa) was calculated for the equation:

Where:

15 g/L and 120 mL/L for X1 and X2 respectively

5 g/L and 40 mL/L for X1 and X2 respectively

For calculating the optimal point, a second order polynomial equation was fitted to the experimental results of CCD as it represented the behavior of such a system more appropriately.

This equation was:

Y = b0 + b1X1 + b2X2 + b1b1X12 + b2b2X22 + b1b2X1X2

Where Y was the response variable (DO), b0 the intercept/constant, b1 and b2 the linear coefficients, b1b1 and b2b2 the squared/quadratic coefficients, b1b2 the interaction coefficients, and X1, X2, X12, X22 and X1X2 were the levels of the independent variables.

Runs were performed in triplicate. The whole statistical procedure of the experimental designs was carried out with the software package Statgraphics Plus® for Windows 5.1 and Microsoft Office Excel software. The quality of the fitness of the polynomial model equation was expressed by the coefficient of determination R2, and the significance was defined as p<0,05.

The biotechnological production process is the result of time-consuming and expensive research and development. For most favorable returns, it is necessary to improve the culture medium, the producer strain and other process parameters to reach a maximal productivity or the highest production capacity (19).

Factorial design: Due to the complexity of the culture medium for growing MG, a RSM was conceived to determine the most favorable composition of the medium for the microorganism growth. In the initial step, a 23 factorial design served as a test to identify the effect of the concentration of Mb, Hs and Ye on MG yields, which indicated that the variable Hs and its interaction with the variables Mb and Ye were not significant in the region studied (p<0,05). The direction of the highest yields was obtained with lower concentrations of Mb and Ye.

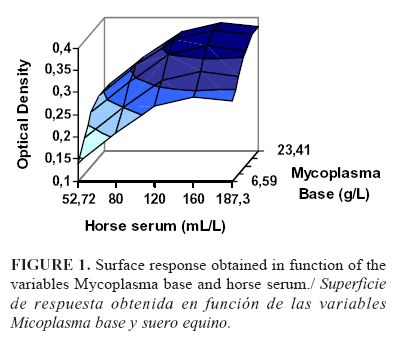

Central Composite Design: A CCD was used to continue this study. Lower concentrations of Mb and Hs were used; additionally, Ye concentration was kept at 6 g/L.

A multiple regression analysis was performed with the result that, in this region, the two variables (Mb and Hs) evaluated and their quadratic interactions were significant, and the mathematical model represented was:

OD = 0,350 + 0,029X1 + 0,040X2 - 0,019X12 - 0,013X22

R2= 0,9265 pmodel = 0,0

Where X1 and X2 represent the coded levels of Mb and Hs, respectively.

As it can be seen, the statistical model obtained was significant and indicated that the equation could explain 92,65% of the response variability. The optimum of these two variables in the region studied corresponded to 18,8 g/L of Mb and 181,6 mL/L of Hs using 6 g/L of Ye. The effect of the culture medium concentration on cell concentration is shown in Figure 1.

The RSM applied for this statistical study had been used for several purposes including medium optimization, metabolites production and extraction conditions. Previously, Pérez et al. (20) studied the culture medium for growing MG produced by OXOID (England) by using this methodology, whit no effect on the expression of antigen proteins, but the yields were low compared with the present work.

Hwang et al. (13) reported that the culture medium composition for biomass production of M. hyopneumoniae was optimized by means of the RSM. They confirmed that fresh yeast extract, horse serum and porcine serum were the major factors influencing mycoplasma protein production. Other authors (21) increased the Human Epidermal Growth Factor expression levels and reduced their degradation rate by optimizing the culture conditions. In other case, Ruiz et al. (22) established a method for obtaining pharmaceutical grade plasmid DNA from Escherichia coli culture together with an optimized purification process.

In order to confirm whether the results obtained by the model could be experimentally reproduced, MG was grown using these conditions (modified supplemented MBM), and cell concentration values of 0,459 ± 0,050 OD units were reached.

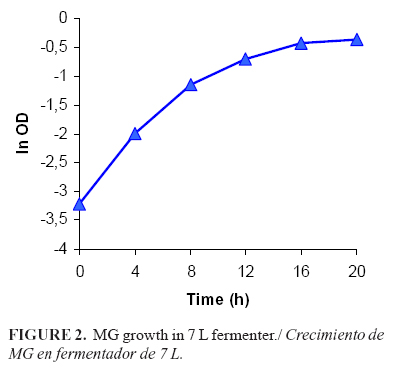

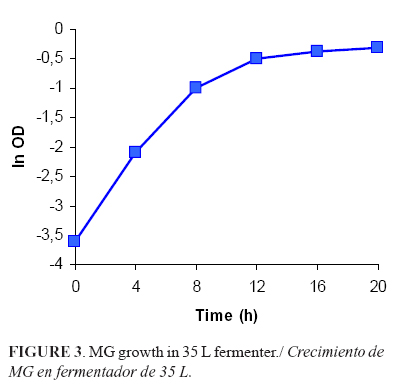

The modified supplemented MBM has been proven in batch fermentation with bioreactors. The growth kinetics in bioreactors 7 and 35 L are represented in Figures 2 and 3 respectively.

During the first 8 hours of growth, a considerably increase of the optical density was observed. Figures 2 and 3 show that this medium reached the end of the exponential growth phase between 8 and 12 hours with a value of the specific growth rate (m) of 0,262 ± 0,002 h-1 in the 7 L bioreactor at 12 hours, which corresponded to a cell yield of 0,599 ± 0,006 OD units and 6.1010 ± 0,48 CFU/mL, higher than (p<0,05) what was obtained with the culture medium before applying the experimental optimization techniques (16). In the 35 L bioreactor at 12 hours, the specific growth rate was 0,213 ± 0,02 h-1 with cell yields of 0,514 ± 0,015 OD units and 5,8.1010 ± 0,43 CFU/mL, yields similar to those obtained at the scale of 7 L.

In summary, the composition of a Cuban culture medium for MG growth was studied with a significant impact on increasing the biomass production at a laboratory or larger scale fermentation process with lower costs.

REFERENCIAS

1. Szczepanek SM, Tulman ER, Gorton TS, Liao X, Lu Z, Zinski J, et al. Comparative Genomic Analyses of Attenuated Strains of Mycoplasma gallisepticum. Infect Immun. 2010;78(4):1760-1771.

2. Colas M, Merino A, Santana Y, Miranda Y, Bacallao N, et al. Serological study of agents associated to chronic respiratory syndrome in laying hens. Biotechnol Appl. 2010;27(3):232-236.

3. Levisohn S, Kleven SH. Avian mycoplasmosis. Rev Sc Tech. 2000;2:425-442.

4. Stipkovits L, Egyed L, Palfi V, Beres A, Pitlik E, Somogyi M, et al. Effect of low-pathogenicity influenza virus H3N8 infection on Mycoplasma gallisepticum infection of chickens. Avian Pathol. 2012;41(1):51-57.

5. Kleven SH. Experiences with live vaccines for Mycoplasma gallisepticum. CENSA, Libro de resúmenes: Taller Internacional de Vaccinología Veterinaria. La Habana (Cuba) 2001.

6. Gharaibeh S, Hailat A. Mycoplasma gallisepticum experimental infection and tissue distribution in chickens, sparrows and pigeons. Avian Pathol. 2011;40(4):349-354.

7. Miles RJ. Cell nutrition and growth. In: Maniloff J (ed). American Society for Microbiology. Mycoplasmas. Washington: 1992, p. 23-37.

8. Varela A, Paret A, Pérez T, Sánchez L, Rosado I, Martínez S. Medio de cultivo para el crecimiento de micoplasmas. Patente concedida por la Oficina Cubana de la Propiedad Industrial. (Cuba). 2003.

9. Pérez T. Desarrollo de una tecnología para la obtención de un candidato vacunal contra la micoplasmosis aviar. Rev Salud Anim. 2004;26(2):143.

10.Pérez T, Sánchez L, Rosado I, Pérez J, Correa H. Caracterización de una emulsión oleosa de células inactivas de Mycoplasma gallisepticum. Rev Mex Cienc Farmacéut. 2008;39(2):5-10.

11.Mu W, Chen C, Li X, Zhang T, Jiang B. Optimization of culture medium for the production of phenyl lactic acid by Lactobacillus sp. SK007. Bioresour Technol. 2009;100:1366-1370.

12.Sánchez L, Moreno AM, Pérez T, Espinosa I. Optimización de un medio de cultivo para el crecimiento de Gardnerella vaginalis. Rev Cubana Invest Bioméd online. 2009;28(2). ISSN 1561-3011. Disponible en: http://scielo.sld.cu/scielo.php?script=sci_arttext&pid=S0864-03002009000200011&lng=es.

13.Hwang MH, Damte D, Cho MH, Kim YH, Park SC. Optimization of culture media of pathogenic Mycoplasma hyopneumoniae by a response surface methodology. J Vet Sci. 2010;11(4):327-332.

14.Li P, Xu L, Mou Y, Shan T, Mao Z, Lu S, et al. Medium Optimization for Exopolysaccharide Production in Liquid Culture of Endophytic Fungus Berkleasmium sp. Dzf12. Int J Mol Sci. 2012;13(9):11411-11426.

15.Chiong A, Sánchez L, Rosado I, Pérez T. Obtención del Banco de Producción de Mycoplasma gallisepticum. Rev Salud Anim. 2003;25(1):62-65.

16.Sánchez L, Pérez T, Rosado I. Producción de Mycoplasma gallisepticum empleando bioreactores del tipo tanque agitado. Tecnol Ciencia Ed. 2002;17(1):42-47.

17.Díaz T, Pita U. La optimización experimental en la industria farmacéutica y biotecnológica internacional. Experiencias en Cuba. I Encuentro Internacional sobre enseñanza de la Química. Editorial ISPJAE. 1996.

18.Barberà E, Tomás X, Molins MB, Moya M. Aplicación del diseño experimental al estudio de medios de cultivo: H. salinarium. Afinidad. 1991;48(431):9-31.

19.Valdés J, Mantilla E, Márquez G, Bonilla RM, Lugo VM, Pérez M, et al. Physiological study in Saccharomyces cerevisiae for overproduction of a homogeneous human epidermal growth factor molecule. Biotechnol Appl. 2009;26(2):166-167.

20.Pérez T, Sánchez L, Díaz T, Rosado I, Rodríguez R. Aplicación del diseño experimental al estudio de un medio de cultivo para el crecimiento de Mycoplasma gallisepticum. Rev Salud Anim. 2001;23(2):80-83.

21.Valdés J, Mantilla E, Márquez G, Bonilla RM, Lugo VM, Pérez M, et al. Improving the expression of Human Epidermal Growth Factor in Saccharomyces cerevisiae by manipulating culture conditions. Biotechnol Appl. 2009;26(1):34-38.

22.Ruiz O, Limonta M, Valdés J, Márquez G, Díaz M, Frómeta W, et al. Physiological and nutritional studies of Escherichia coli and a new combination of separation methods to obtain highly pure and homogeneous plasmid DNA for gene therapy. Biotechnol Appl. 2012;29(4):271-274.

Recibido: 22-11-2013.

Aceptado: 27-3-2014.

*Corresponding author: Tania Pérez Bueno. Tel. (+53)47 86 3014; (+53)47 849164; E- mail: bueno@censa.edu.cu.