INTRODUCTION

Due to the low durability performance of the construction-fabrication materials exposed to the impact of the aggressive coastal environment of the atmosphere, ashort project service life has been demonstrated in thecoastal infrastructures around the world. It is an engineering problem very difficult to solve worldwide, particularlyin highly developed countries in charge of the production and commercialization of materials for the Construction-Manufacturing Industry (CMI). Ashort projectservice life of infrastructureprojected to operate in coastal zones of high construction potentialcausescostly repair works very high on a global scale (Koch, et al, 2012; Castañeda, et al, 2014 and 2020).

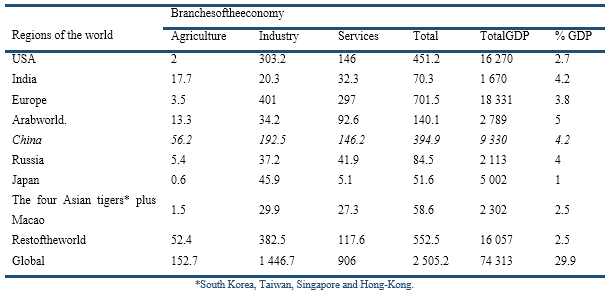

The People's Republic of China is the first country in producing and marketing materials for the CMI worldwide. Annual exports of approximately US$2,157 million representing 31% of GDP are reported. However, due to the low durability performance of the metallic materials most used in the CMI in its large coastal zone, the country is among the first regions in the world until 2020 in terms of global economic losses associated to atmospheric corrosion phenomenon in different sectors of the economy (Table 1). (Mohammad, 2020).

Table 1 Global losses (Billion US$) due to atmospheric corrosion in different sectors of the economy in regions of the world until 2020.

To carry out studies between two nations, one characterized by very high production and commercialization of metallic materials for CMI as China, and the other forpresenting a very high impact of the aggressive coastal environment of the atmosphere on the materials as Cuba, itis very necessary. Metallic materials are widely used in the construction and manufacture of infrastructure. Nevertheless, thermoplastic and thermosetting polymeric materialsshould be alsoevaluated in these types of research studies.

The main objective of this research project proposal is: To define the requirements by durability of metallic and polymeric construction-manufacturing materials of Chinese origin exposed to the impact of the aggressive coastal environment of Cuba's atmosphere.

According to the research projects carried out in the last century (MICAT, PATINA, ISOCORRAG, ICP/UNECE) (Morcillo, et, al 2002;Belén, et al, 2017),as well as in other studies more current carried out in the present century (TROPICORR, DURACON, PREVENIR), (Rocha, 2003; Troconis, et al; 2007), this experience has not been considered. Research studies carried out in coastal zones of high construction potential generally in Latin American, European and Asian countries, excluding China, evaluated the impact of the aggressive coastal environment of the atmosphereindependentlyon their own metallic materials most used in the CMI (carbon steel, zinc, copper and aluminum) based on atmospheric corrosionphenomenon. Regardingto the studies carried out at the beginning of this centuryon atmospheric corrosionphenomenon, the indoor exposure conditions to the atmosphere under the stove effect was usedin Latin American countries (TROPICORR) for metallic materials (carbon steel, copper, tin and nickel), simulating electronic equipment and components. In the case of the DURACON and PREVENIR projects, also in Latin America, atmospheric corrosion o reinforcement steel was evaluated in reinforced concrete specimensexposed to the impact of the aggressive coastal environment of the atmosphere. Thermoplastic and thermosetting polymeric materials that will be considered in this research project proposalwere not included in any of the studies carried outpreviously.

On the other hand, the influence of climate change from an increase in the global temperature of the atmosphere, the height above sea level and wind speed gradually accelerates the deterioration phenomena over time on CMI materials in coastal zones (Castañeda, et al, 2009 and 2018). Due to them frequent occurrence of meteorological events such as tornadoes, severe local storms and tropical cyclones, the wind speed results in a much higher impact of the aggressive coastal environment of the atmosphere (Marrero, et al, 2020).

As a scientific problem in this research project proposal is considered: To mitigate the anticipated deterioration in the infrastructure due to atmospheric corrosion and other deterioration phenomena; the China's construction-manufacturing materials, needs a higher durability performance, before proceeding with construction work in coastal zones of high construction potential.

Coastal zones are identified for havinghigh construction potential worldwide, not only by the growing development of the tourism industry. In order to take advantage of seawater in cooling systems, most of the chemical industries (refineries, thermoelectric plants, and others) are built at short distances to the coastline. Ports, which are of great economic interest, the infrastructure is built and manufactured using the metallic materials most used in the CMI.China has a very large built-up coastal infrastructure with approximately 350 ports, 179 refineries and 60 wind farms.

To ensure a long project service life in the coastal infrastructures such as China's, an increase in the costs when building or fabricating with requirements by durability established in the materials exist. However, in developed countries and coastal regions, the current worldwide trend is opposite (Table 1). The structures and manufacturing equipmentsare built and manufacturedrespectively without the requirementsby durability, dependent on the adequate quality of the materials and their primary and secondary protection systems, generally based on coatings, withoutalso considering the impact of the aggressive coastal environment of the atmosphere. Costs invested in unexpected repair works are often up to 10 times higher than the initial construction and manufacturing costs due to the rapid appearance ofdeterioration phenomena in the materials at the time of exposure(Hernández, 2006; Xianming, et al, 2012).The most common deterioration phenomena caused by the impact of the aggressive coastal environment of the atmosphere are: atmospheric corrosion in metallic materials and in reinforcement steel embedded in reinforced concrete, as well as aging of polymeric materials.

Atmospheric corrosion is understood as the electrochemical attack suffered by metallic materials exposed to the atmospheredirectly (open atmosphere) or indirectly (indoor exposure condition), causing their deterioration in a muchaccelerated manner over time (Viña, et al, 2021). The deterioration or degradation of thermoplastic or thermosettingpolymeric materials, exposed to natural exposure medium (atmosphere) in coastal zones, leads to a change in properties such as tensile strength, color and shape, under the influence of one or more environmental factors as heat and intensity of solar radiation. Changes in the properties leads to an "aging" (Schweitzer, 2006). In both cases, the materials most used in the CMI lose their mechanical, technological, physical and chemical properties quickly over time. A long project service life for the infrastructures exposed to the impact of the aggressive coastal environment of the atmosphere is not guaranteed. Due to its great extension, the atmosphere is the natural environment of exposure to which majority of the infrastructures built and manufactured with the materials most used in the CMI are exposed (Pierre, 2008). Among the metallic materials produced in China for the CMI that need to be further studied exposed to a very high impact of the aggressive coastal environment of the atmosphere, as that of Cuba are: copper and aluminum, widely used in the electro-electronic industry for the manufacture of equipment and components, and its alloys as bronzes, brasses and cupro-nickels in the copper. Duralumin and silumines as in the aluminum alloys are widely used in the manufacturing of equipment and accessories in the chemical industry. Stainless steels areincluded. Due to their light weight, aluminum and its alloys are also widely used in the aviation industry. The 90% of zinc production is destinedfor the manufacturing of galvanized steels. Carbon and galvanized steels are widely used in the construction industry due to their exceptional virtues of very high mechanical resistance. However, its chemical resistance (to atmospheric corrosion), when exposed to the impact of the aggressive coastal environment of the atmosphere, is low. Among the polymeric materials (thermoplastics) also from China, and the most used in the construction industry is the High Density Polyethylene (HDPE). Low density polyethylene (LPDE), polystyrene, Teflon and PVC (polyvinyl chloride) are widely used in the electro-electronic industry for the manufacture of equipment and components.

The parameter that can identify the impact of the aggressive coastal environment of the atmosphere is the aggressivity corrosion or corrosivity of the atmosphere. (Howland andCastañeda; 2017). It is the capacity of this natural exposure environment to cause and develop the atmospheric corrosion phenomenon in metallic materials and deterioration phenomena in other types of materials for the CMI. According to atmospheric corrosion specialty standards, the corrosivity category of the atmosphere depends of the annual atmospheric corrosion rate values determined on standardized dimensionssamplesof the metallic materials most used in the CMI (carbon steel, zinc, copper and aluminum). The categories can be classified as: very low (C1), low (C2), medium (C3), high (C4), very high (C5) and extreme (CX). Corrosivity categories of the atmosphere obtained, before proceeding with the construction-manufacturing works in coastal zones of high constructive potentialis a very valuable engineering tool that forces to establish the requirements by durability based on the adequate selection of materials for the CMI and its protection systems (Norma ISO 9223-2012). In other words, the durability begins with the construction or manufacturing design. An aspect that is generally forgotten or not considered.

The current standard of the atmospheric corrosion specialty establishes that, although the corrosivity categories of the atmosphere are referenced for the metallic materials most used in the CMI, they can be used as a reference to different types of metallic alloys, ceramics and polymeric materials when the requirements for durability are established (Norma ISO 9223-2012). This engineering requirement was not required in the previous standards used in the studies carried out in the last century and at the beginning of the present century (Norma ISO. 9223-1992). To include in these types of studies other materials widely used in CMI such as polymeric materials, mainly thermoplastics and thermosets, is very necessary. Thermosetsmaterials such as Teflon are very resistant to high temperatures. Corrosivity categories of the atmosphere very high (C5) and extreme (CX) have caused deterioration and aging phenomena very accelerated in ceramics (bricks) and polymeric (elastomeric) materials, as well as in the reinforced concrete inthe aggressive coastal environment of Cuba's atmospherein coastal zones of high constructive potential (Reinosa, et al, 2007; Carvajal, et al; 2011 andCastañeda, et al; 2012). All material that withstands in the long term the very high impact of the aggressive coastal environment of Cuba's atmosphere, through the previous requirements by durability defined can be used in any coastal zone of high constructive potential worldwide. Along project service life of the infrastructures for more than 50 years, without the execution of unexpected costly repair works is guaranteed.

Studies on the impact of the aggressive coastal atmospheric environment in Cuba.

Several studies on the impact of the aggressive coastal environment of the atmosphere, or what is the same, of aggressivity corrosion of the atmosphere, have been carried out in coastal zones of high constructive potential in the last ten years in Cuba. The corrosivity categories of the atmosphere very high (C5) and extreme (CX) have prevailed for the metallic materials most used in the CMI (carbon steel, zinc, copper and aluminum), as well as for reinforced concrete structures (Howland, et al, 2019). The metallic materials used in previous studies and those currently in use are of European origin, mainly from Russia. Thermoplastic and thermosetting polymeric materialswere not included in the studies carried out. The most important studies were carried out in: the zoneof the highest potential for wind energy generation, located on the northern coast in the province of Holguín, in the eastern part of the country. The wind farm is located 60 mfrom the coastline (Castañeda, et al, 2015 and 2016). The special industrial harbor zone located at the west of Havana (Fernández and Castañeda, 2015). The lucid avenue of the Havana Seawall was included (Valdés, et al, 2019). Other studies were carried out at the Havana oil refinery and in the oil extraction zones located just east at Havana (Valdés, et al, 2020; Castañeda, et al, 2020 and 2021). Due to the very high relative humidity and chloride deposition rate levels, the humid deposition of chloride ion salts deposited in saline solutionform, has been the fundamental factor in the origin and development of the atmospheric corrosion phenomenon in carbon steel, and galvanized steel and aluminum. On the other hand, the deposition of sulfur compounds or sulfate ion salts, also in saline solutionform, has had a great influence on copper. In order to guarantee a long project service lifefor the all infrastructure being built in coastal zones of high construction potential in Cuba, the results obtained have allowed the elaboration of standards. Requirements for durability of materials obtained are included. (NC: ISO 12944-2018; NC-120:2019). This experience was precisely valued by the National Research Institute of Electro-Electronic Equipment of Guangzhou China for the execution of this research project, through the existing publications in indexed journals.

Corrosivity category of the atmosphere higher than extreme (CX) for carbon steel has been obtained in the studies carried out in the zones of the Havana Seawall (Castañeda, et al; 2023). Values around 6 870 g m-2a-1higher than the maximum value established in the classification interval of extreme [1500 < CX ≤ 5 500 g m-2 a-1] are reported at short distances from the coastline (Norma ISO 9223; 2012). A thickness loss of 0.874 millimeters per year was obtained. The intense deterioration due to atmospheric corrosion in two of the three carbon steel specimens, placed in a zone of the Havana seawall at a short distance from the coastline during a time of exposure of one year is shown. (Fig. 1).

According to forecasting models, this new category may remain in both zones up to 20 years of exposure of this metallic material, which is widely used in the construction industry worldwide in coastal zones (Castañeda, et al; 2018). So far, only one annual atmospheric corrosion rate value (6 791.04 g m-2a-1) indicative of a corrosivity category of the atmosphere higher than extreme (>CX) for carbon steel, was reported in the late 1990s in the coastal atmospheric corrosion station in La Vozat north of Maracaibo, Venezuela, located at a distance of 15 m from the coastline (Corvo, et al, 1997). The highest annual atmospheric corrosion rate value for carbon steel reported in Cuba in the 1980s was 3566 g m-2a-1 (CX), in a coastal zone of high constructive potential at short distances from the coastline and very close to the Havana seawall zone (Corvo, et al, 2008).

According to the results presented in the MICAT project (Ibero-American Map of Atmospheric Corrosion) concluded in the first five years of the 1990s, where 75 coastal atmospheric corrosion station were distributed among the 14 participating countries in Ibero-America (Belén, et al, 2017). The corrosivity category of the atmosphere extreme (CX) for carbon steel was obtained only in four coastal atmospheric corrosion stationlocated at short distances from the coastline. The highest value of annual atmospheric corrosion rate was determined in the locality of Cojímar, located east of Havana City at 150 m from the coastline (Table 2).

On the other hand, corrosivity categories of the atmosphere for other metallic materials such as copper, zinc, aluminum, has been classified between very high (C5) and extreme (CX) from one to 20 years in coastal zones of Cuba in the last century and in the present (Mendoza andCorvo, 2000; Corvo, et al, 2009).

Due to its geographical condition as an island, Cuba is an ideal country to carry out these types of studies based on evaluating the impact of the aggressive coastal environment of the atmosphereon the durability of materials for the CMI of highly developed countries, before proceeding with the construction and manufacturing worksin the coastal zone. Hence, the interest shown by the National Research Institute of Electro-Electronic Equipment of Guangzhou China, in exposing to the impact of the aggressive coastal environment of Cuba's atmosphere at short distances from the coastline, its metallic materials for the CMI either bare or with its primary and secondary protection systems, generally based on coatings.

Others studies of great magnitudebased on evaluating the impact of the aggressive coastal environment of the atmosphere on the metallic materials most used in the CMIhave been carried out in the present centuryin coastal zones of high constructive potential located in: India (Natesan, et al, 2006), Saudi Arabia (Syed, 2008), Brazil (Kenny, et al, 2009), Colombia (Castaño, et al, 2010), United Arab Emirates (Ganther, et al, 2011), Mexico (Mariaca, et al, 2014), Spain(Alcántara, et al, 2015), Chile (Vera, et al, 2018), Russia (Panchenko, et al, 2017), Ecuador (Guerra, et al, 2018), Thailand(Palsson, et al, 2019), Canary Islands-Spain (Santana, et al, 2019)and even in China itself (Zhi, et al, 2020). Each country evaluated its own metallic materials for the CMI, mainly carbon steel. Polymeric materials were not included in any of the studies carried out. Acorrosivity category of the atmosphere higher than extreme (>CX) for carbon steel was not found. Due to its high mechanical strength, carbon steel has been the metallic material most studied. This appreciated metallic material has yield strength (σf) and breaking strength (σB) much higher compared to zinc, copper and aluminum.

Studies on the impact of the aggressive coastal atmosphere environment in the people's Republic of China.

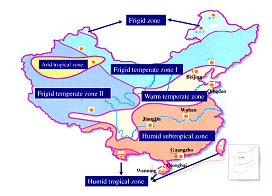

Due to its large territorial extension, the People's Republic of Chinahas different types of climates (Fig. 2). According to a very comprehensive study about the impact of the aggressive coastal environment on the atmosphere reported in the second five-year period of the present century, 13 outdoor exposure sites were placed in different climates for a time of exposure of 10-year. Seven of the outdoor exposure sites were placed in coastal zones of high construction potential. Anoutdoor exposure site was precisely placed in the port city of Guangzhou (Fig. 2) (Dong, et al, 2007). To demonstrate the atmospheric corrosion resistance of the metallic materials most commonly used in the CMI of national production exposed to the impact of coastal atmospheric environment, was the main objective of the study. This is the experience we intend to carry out in Cuba.

The metallic materials most used in the CMI, including low alloy steels and thermoplastic and thermosetting polymeric materials, will be exposed tothe impact of the aggressive coastal environment of Cuba's atmospherealso for time of exposure from one to 10 years, with corrosivity categories of the atmosphere very high (C5), extreme (CX) and greater than extreme (> CX). As has been shown, these corrosivity categories of the atmosphere are not typical in coastal zones of high construction potential in China.Any construction material, as well as its protection systems that are durableexposed to these categories, based on the requirements for durability that will be defined in the course of the research, itis a supreme guarantee to proceed with theconstruction and manufacturing worksof the infrastructurein any coastal zone of high constructive potential worldwide.

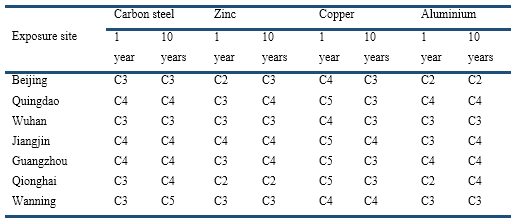

Atmospheric corrosion deterioration of metallic materials depended on the corrosivity categories of the atmosphere determined at the seven outdoor exposure sites located in coastal zone of high construction potential in China. These categories were lower than those determined in the tropical coastal climate of Cuba. The category very high for carbon steel (C5) was obtained only in the coastal zone of Wanning after ten years of exposure of the specimens (Table 3). Due to high depositions of sulfur compounds and NO2 concentrations in China's atmosphere, copper was the metallic material most affected (Ma, et al, 2009 and 2010). These are two aggressive agents very dangerous for copper and its alloys.

Other atmospheric corrosion studies more recent reported in 2020 were also carried out in the coastal cities of Wanning and Guangzhou in southeast China for two other types of low alloy steel (Q235 and Q345) that tend to be referred to as Weathering Steel. Both metallic materials widely used also in the construction industry were exposed to corrosivitycategories of the atmosphere medium ([250 < C3 ≤ 400 g m-2a-1] - Guangzhou) and high ([400 < C4 ≤ 650 g/m-2a-1] - Wanning) in theoutdoor exposure sites placed in both coastal cities during one year of study (Huang, et, al, 2020).

Atmospheric corrosion studies using the atmospheric corrosion monitoring sensors (acms).

Despite the novel results demonstrated in Cuba, the atmospheric corrosion had been never before studied in the metallic materials most used in the CMIusingthe ACMS. This same situation occurred in all studies referenced previously carried out in the last century, as well as in the present one. No references have been found in Latin America where atmospheric corrosion for the materials most used in the CMI has been studied using ACMS. However, a preliminary study based on the use of electrochemical copper sensors in acidic, neutral and alkaline under immersion conditions and thin film, as in the atmospherewas carried out by researchers from the Corrosion Research Center of the Autonomous University of Campeche (Corvo, et al 2015).

The first experience in Cuba will be acquired from the execution of this research project proposal. An ACMS as the one shown, with its corresponding computer support, will be donated by the National Research Institute of Electro-electronic Equipment of Guangzhou China (Fig. 3).

The sensor will be installed under outdoor exposure conditions in the coastal atmospheric corrosion station of the Center for Industrial Quality Technology belonging to the Ministry of Industry (MINDUS), located 150 m from the coastline in the Cojímartown at east of Havana City, Cuba (23.16807, -82.30876). This station has been widely used in atmospheric corrosion studies in Cuba from the 1980s to the present (Fig. 4) (González, 2005). Precisely in this station, standardized specimens of metallic and polymeric materials from China will be tested.

Fig. 4 Coastal atmospheric corrosion station located 150 m from the coastline in the ojímartown at east of Havana City, Cuba.

Due to unreliability in results achieved in the atmospheric corrosion phenomena under accelerated conditions of exposure in climatic and/or saline chambers for short periods of time, ACMS have been used lately (Martínez, et al, 2019). Transient processes occurring in the atmosphere that influence the impact of the aggressive coastal environment are not simulated by the chambers. It works under stationary and not transient conditions. The penetration of marine aerosol, variations in relative humidity, temperature, solar radiation intensity, wind strength and direction, aggressive agent’s deposition, as chloride and sulfate ion salts in saline solution form on the materials surface exposed, occur during the day (Meira, et al, 2018). These processes tend to accelerate the atmospheric corrosion phenomenon in metallic materials, in the reinforcement steel in reinforced concrete and aging in polymeric materials.

The ACMS allow the determination of the atmospheric corrosion rate instantaneously, that is to say, in real time, as well as in cumulatively time, coupled to Potentiostat-Galvanostat equipment. Electrochemical techniques of direct current (DC) and alternating current (AC) such as Polarization Resistance (PR) and Electrochemical Impedance Spectroscopy (EIS) respectively are used (Cao, et al, 2005, Cai, et al, 2005). These sensors have also allowed the determination of the thickness of the condensed water film and its residence time (Time of Wetness) on metallic materials using the EIS (Wall, et al, 2005, Wan, et al, 2019). In both cases, simulating Very Low (C1) and low (C2) corrosivity categories of the atmosphere for the metallic materials most used in the CMI. These categories are not very typical in an aggressive coastal atmosphere environment such as that of Cuba.

On the other hand, the ACMS have also been used in the interior of cars in Japan for the last ten years, with the purpose of really knowing when maintenance work should be started, without going to the costly repair work (Fig. 5 a) y b) (Mizuno, et al, 2014).

In other words, is important to ensure that automobiles, when frequently transit through by coastal zones, maintain their initial conditions of project service life over time, such as aesthetics, functionality and safety.

Atmospheric corrosion has also been studied recently on the European continent using ACMS. However, the ACMS were placed in urban zones. The corrosivity categories of the atmosphere wereclassified as Very low (C1) and low (C2) for carbon steel (Kreislova and Vlachova, 2021). Another very similar experience was obtained in South Korea (Li, et al, 2006). The ACMS were not exposed to the impact of the aggressive coastal environment of the atmosphere with corrosivity categories from high (C4) to extreme (CX) for the metallic materials most used in the construction industry. It was demonstrated that these sensors constitute a safe and effective tool for the monitoring and study of atmospheric corrosion, but in zones where there is no severe impact of the aggressive coastal environment of the atmosphere, such as Cuba.

Atmospheric corrosion studies in the People's Republic of China using ACMS have been carried out from the beginning of the 21st century to the present (Pei, et al, 2020). Atmospheric corrosion has been measured in building metallic materials such as carbon steel and copper in the coastal harbor city of Qingdao (Fig. 6) (Pei, et al 2020).

Fig. 6 ACMS electrochemical sensor placed in the atmospheric corrosion station of Qingdao City, China.

However, ACMS have not been exposed to corrosivity categories of the atmosphere very high (C5), extreme (CX) and higher than extreme (>CX) in coastal zone of high constructive potential. This is another scientific interest based on demonstrating the effectiveness of electrochemical ACMS in Chinese-made in the future no very long time, exposed to the impact of the aggressive coastal environment of Cuba's atmosphere.

A very significant data miningusing these sensors in China exposed to very short exposure periods under real atmospheric exposure conditions had been guaranteed. The results obtained have facilitated the development of models for forecasting the impact of the coastal atmospheric environment on CMI materials using automated software that supports the use of random data, Artificial Neural Networks and vector regression models. (Kamrunnahar and Urquidi-Macdonald, 2010 and 2011). The results obtained showed that the automated softwares that support the use of random data were more effective in determining the most influential factors in atmospheric corrosion in the metallic materials most used in the CMI, as well as in establishing more accurate and precise mathematical statistical models based on forecasting the impact of the coastal atmospheric environment, that it to say the corrosivity categories of the atmosphere. This experience will be acquired from the ACMS that will be placed in the coastal atmospheric corrosion station located in Cojímar to the east of Havana City, Cuba.

The coastal aggressive environment of the atmosphere based on obtaining the aggressivity corrosion, has been predicted from two to 20 years in Cuba and worldwide generally using the forecasting model established in the standards of the atmospheric corrosion specialty ((Norma ISO 9224, 2012). A very high precision and accuracy obtained have been demonstrated in coastal zones of high construction potential of Russian (Panchenko, et al, 2017). The comparison, between forecasting models obtained from the specialty standards, and the data mining provided by the electrochemical ACMS exposed to the severe impact of the aggressive coastal environment of the atmosphere such as that of Cuba, would be a scientific novelty. The results obtained could demonstrate of ACMS effectiveness for future commercialization in Cuba and in countries of the Caribbean region with coastal zones of high construction potential.

CONCLUSIONS

The durability of the materials most used in the CMI of Chinese origin, will be studied on the impact of the aggressive coastal environment of Cuba's atmosphere, through the Research project proposal between the two countries.Research studies between two countries, one characterized by a very high production and commercialization of metallic materials for CMI such as China, and the other by a very high impact of the aggressive coastal environment of the atmosphere on the materials such as Cuba, were not found. The requirements by durability that are intended to be defined will guarantee higher a long project servicelife to all the infrastructure to be built or manufactured, mainly in any coastal zone worldwide. A very significant economic benefit for developing countries is expected. In this way, the infrastructure exposed to the impact of the coastal atmospheric environment in any coastal zone worldwide, will never reach its residual service life without functioning and economic-social contribution, leaving behind its ultimate service life. According to the bibliographic review, Cuba, as an island with a tropical coastal climate, in addition to the high relative humidity and deposition of chloride ion salts in the form of saline solution, is an ideal country for the execution of these studies. A new corrosivity category of the atmosphere higher than extreme (>CX) for carbon steel was reported. The corrosivity category of the atmospherereported in China for the metallic materials most used in the CMI have been lower than those determined in the tropical coastal climate of Cuba.